Imagine a device that precisely controls the flow of liquid in your plumbing or HVAC system, ensuring optimal performance and efficiency. That’s exactly what a double regulating valve does. But how does it work, and where can it be applied? If you’re new to the world of valves, you’re in the right place. This beginner-friendly guide will take you through the fundamentals of double regulating valves, explaining their working principles and mechanisms. You’ll discover their diverse applications, from HVAC systems to plumbing, and learn about the benefits they offer. By the end of this article, you’ll be equipped with the knowledge to select and install the right double regulating valve for your needs. Ready to dive in? Let’s get started!

Introduction to Double Regulating Valves

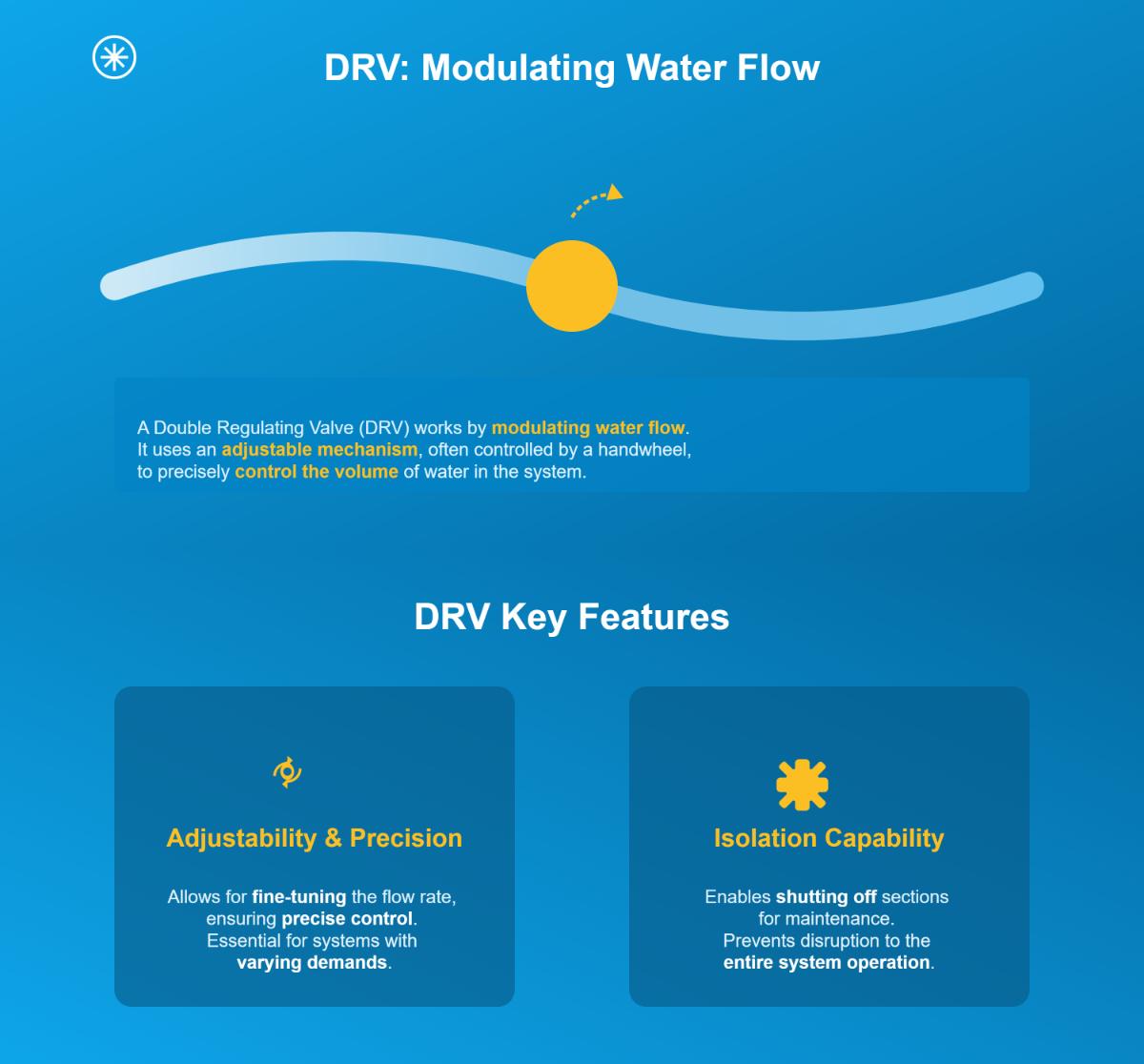

Double Regulating Valves (DRVs) are essential components in HVAC (Heating, Ventilation, and Air Conditioning) and plumbing systems, designed for precise water flow and pressure control. DRVs modulate water flow through an adjustable internal mechanism, typically using a handwheel, allowing for precise setting and consistent performance. This feature is particularly useful during system commissioning and maintenance, as it allows for easy isolation of sections without disrupting the entire system. By enabling accurate balancing of water flow, DRVs help ensure optimal system efficiency and performance, reducing energy consumption and improving overall comfort.

Types of Double Regulating Valves

- Fixed Orifice DRVs: Maintain a constant flow rate based on the orifice size and pressure differential, ideal for stable flow demands.

- Variable Orifice DRVs: Allow for flow rate adjustments by changing the orifice size, suitable for systems with varying loads.

- Pressure Independent Control Valves (PICVs): Combine balancing and control functions, ensuring exact flow rates regardless of system pressure changes.

Key Features and Benefits

- Precision Flow Control: Ensures stable system performance.

- Pressure Management: Mitigates pressure surges, protecting the system.

- Isolation Capabilities: Allows section isolation for maintenance without disrupting – Energy Efficiency: Maintains optimal flow rates for energy savings and extended system lifespan.

Applications of Double Regulating Valves

DRVs are utilized in a variety of applications, including:

- Fan Coils and Air Handling Units: To ensure efficient heating and cooling operations.

- Boiler Systems: For regulating hot water flow in different temperature systems.

- Domestic Hot Water Systems: To maintain consistent water temperature.

- Industrial Heating Systems: For system balancing and commissioning.

Installation and Maintenance Tips

- Material Selection: Choose durable materials like brass or stainless steel.

- Verification: Ensure the valve’s fail position aligns with system requirements during installation.

- Regular Calibration: Maintain valve accuracy with advanced measurement tools.

Working Principle of Double Regulating Valves

Mechanism of Double Regulating Valves

Double Regulating Valves (DRVs) control water flow within a system through an internal mechanism that adjusts the valve opening. This mechanism typically consists of a movable element, such as a disc or plug, which changes the size of the passage through which the water flows. By turning the handwheel or actuator, the operator can increase or decrease the flow rate, ensuring the desired flow is maintained despite pressure fluctuations.

Operation of Double Regulating Valves

Manual Adjustment

DRVs are generally operated manually using a handwheel, which moves the internal mechanism to either open or close the valve. The exact position of the valve can be set during the system’s commissioning phase and locked in place to maintain the required flow rate. This locking feature is essential for ensuring that the settings remain consistent over time, even after routine maintenance or system shutdowns.

Flow Regulation

The primary function of DRVs is to regulate the flow of water through a system by adjusting the valve opening to control the water volume. The valve can be finely tuned to achieve precise flow rates, which is crucial for maintaining system balance and efficiency. Additionally, many DRVs come equipped with pressure test points that allow for accurate measurement and verification of flow rates.

Pressure Management

DRVs play a critical role in managing pressure within fluid systems. They help absorb and mitigate pressure surges, which can occur due to sudden changes in flow demand or system pressure. This helps protect the system from damage and ensures smooth operation. This pressure management capability is particularly valuable in HVAC and plumbing systems, where maintaining consistent pressure is essential for optimal performance.

Types of Double Regulating Valves

Fixed Orifice DRVs

Fixed orifice DRVs maintain a constant flow rate based on the size of the orifice and the pressure differential across the valve. These valves are ideal for systems with stable flow demands, where the flow rate does not need to be adjusted frequently.

Variable Orifice DRVs

Variable orifice DRVs allow for adjustments in the flow rate by changing the size of the orifice. These valves are suitable for systems with varying loads, where the flow rate needs to be adjusted to match changing demand conditions.

Pressure Independent Control Valves (PICVs)

PICVs are advanced DRVs that maintain a constant flow rate even when system pressure changes, making them highly efficient for dynamic systems with fluctuating pressure conditions.

Key Features

- Locking Mechanism: Keeps the valve set at the desired position for consistent flow rates.

- Pressure Test Points: Allow for precise flow regulation by measuring differential pressure.

- Advanced Models: PICVs provide exact flow rates with each spindle turn, making system balancing easier and more efficient.

By understanding the working principle of Double Regulating Valves, operators can effectively manage and optimize their fluid systems, ensuring reliable performance and efficiency.

Valve Mechanism

Internal Mechanism

The internal mechanism of a Double Regulating Valve (DRV) is crucial for controlling water flow in the system. This mechanism typically includes a movable disc or plug that can be adjusted to vary the size of the opening through which water flows. By turning a handwheel or actuator, the user can open or close the valve to the desired position, effectively controlling the flow rate.

Flow Control

The main purpose of a DRV is to regulate water flow by adjusting the internal mechanism to modify the flow passage. The handwheel or actuator allows precise control over the valve position, which in turn adjusts the flow rate. Once set, the valve can maintain this flow rate consistently, even if the valve is closed and then reopened.

Locking Mechanism

To ensure that the settings remain consistent over time, DRVs are equipped with a locking mechanism. After the desired flow rate is set, the valve can be locked in place. This feature prevents unintentional changes to the flow settings, ensuring efficient and reliable system operation.

Pressure Management

DRVs maintain consistent system pressure by adjusting the flow rate, which helps prevent damaging pressure surges. The ability to manage pressure effectively is a key feature of DRVs, contributing to the overall stability and safety of hydraulic systems. This precise control ensures that components and equipment operate optimally, reducing the risk of wear and tear and extending the lifespan of the system.

Pressure Test Points

Many DRVs come equipped with pressure test points. These are small ports on the valve body that allow for the measurement of differential pressure across the valve. Operators can verify the flow rate and correct valve settings by connecting pressure gauges or sensors to these test points. This feature is essential for accurate system balancing and efficient operation.

Types of Mechanisms

Globe Valve Mechanism

Globe valves use a linear motion to move a disc or plug against a seat. This design minimizes turbulence and provides precise control over the flow rate. Globe valves are ideal for applications requiring fine adjustments.

Ball Valve Mechanism

Ball valves utilize a spherical ball with a hole through the center. Rotating the ball by 90 degrees opens or closes the flow passage. This mechanism is known for its simplicity and quick operation, making it suitable for high-pressure systems.

Butterfly Valve Mechanism

Butterfly valves use a rotating disc to control flow. The disc can be turned to various angles, allowing for precise flow adjustments. Butterfly valves are lightweight and cost-effective, making them suitable for large-scale systems.

Calibration and Adjustment

Proper calibration of DRVs is crucial for optimal performance. During system commissioning, the valve should be adjusted incrementally, with careful monitoring of the system’s response. Using digital flow meters and pressure sensors helps establish baseline performance and ensures that the valve settings are accurate.

Understanding the internal mechanism and features of Double Regulating Valves is essential for effectively managing and optimizing fluid systems. This knowledge allows operators to maintain consistent flow rates, manage pressure efficiently, and ensure reliable system performance.

Applications of Double Regulating Valves

HVAC Systems

Double Regulating Valves (DRVs) play a crucial role in HVAC systems, managing water flow in components like fan coil units, air handling units, and chilled water systems. By precisely controlling water flow, DRVs ensure desired temperatures are maintained efficiently, optimizing the performance of heating and cooling systems. This precise control helps in providing consistent comfort and reducing energy consumption.

Plumbing

In plumbing systems, particularly in residential settings, DRVs help maintain consistent water temperatures in fixtures such as showers and faucets, preventing sudden changes due to other water usage activities like toilet flushes. This ensures a comfortable and stable water supply, enhancing user experience and preventing discomfort caused by abrupt temperature fluctuations.

Industrial Applications

In industrial settings, DRVs are used to precisely control flow and pressure in systems that handle high temperatures and pressures, ensuring reliable performance and safety. Their ability to manage such demanding conditions makes them suitable for various industrial applications, maintaining operational efficiency and system integrity.

System Balancing

In multi-branch piping systems, DRVs balance the flow across different branches, ensuring each section receives the correct amount of fluid, which is crucial for optimizing system performance and energy use. Proper system balancing achieved through DRVs helps in reducing energy consumption and improving the efficiency of the entire fluid distribution system.

Commissioning and Maintenance

During the commissioning phase of a fluid system, DRVs are set to achieve the desired flow rates. This initial setup is crucial for ensuring that the system operates efficiently from the start. Additionally, DRVs facilitate easy adjustments during maintenance without disrupting the entire system.

Benefits of Using Double Regulating Valves

- Enhanced Efficiency: By maintaining stable flow rates and pressure, DRVs contribute to the – Improved Comfort: Consistent water temperature and flow in residential applications enhance user experience, making DRVs essential for comfort in heating and cooling systems.

- Longevity of Systems: Properly functioning DRVs help extend the life of HVAC and plumbing systems by preventing damage caused by pressure fluctuations and ensuring optimal performance over time.

Double Regulating Valves in HVAC Systems

Key Functions of Double Regulating Valves in HVAC Systems

Double Regulating Valves (DRVs) play a pivotal role in maintaining the efficiency and performance of HVAC systems. Here are some of their key functions:

- Precise Flow Control: DRVs accurately adjust water flow rates, optimizing system performance.

- Pressure Management: DRVs manage and stabilize pressure variations, preventing damage from surges.

- Temperature Control: By maintaining consistent flow and pressure, DRVs ensure stable temperatures and reduce energy consumption and costs.

Applications in HVAC Systems

Double Regulating Valves are vital in various HVAC applications:

Fan Coils and Air Handling Units

In fan coil units and air handling units, DRVs adjust water flow for desired temperature control, ensuring consistent indoor climates and improving system efficiency.

Chilled Water Systems

DRVs are often installed in chilled water systems, particularly on return lines, to maintain steady flow rates despite pressure fluctuations. This stability ensures that the cooling systems operate efficiently and effectively.

Central Heating Systems

In central heating systems, particularly in high-rise buildings, DRVs help balance water flow across different floors and zones. This balancing act is critical for maintaining consistent heating levels and avoiding hot or cold spots within the building.

Comparison with Balancing Valves

While both balancing valves and double regulating valves are used to manage water flow in HVAC systems, they serve slightly different purposes:

- Balancing Valves: Primarily used for detailed flow management in larger systems to ensure even fluid distribution across all branches.

- Double Regulating Valves: More suitable for smaller systems requiring precise flow and pressure control. DRVs combine both regulating and isolating functions, eliminating the need for separate valves.

Installation and Maintenance

Proper installation and regular maintenance of DRVs are essential for their optimal performance:

Installation Tips

- Compatibility: Ensure that the valve’s specifications match the system requirements.

- Accessibility: Install the valve in a location that is easy to access for future adjustments and maintenance.

- Alignment: Make sure the valve is properly aligned with the system’s piping to prevent leaks and ensure smooth operation.

Maintenance Guidelines

- Regular Checks: Periodically verify that the valve settings are correct and adjust if necessary.

- Preventive Maintenance: Inspect the valves for signs of wear or blockages and address any issues promptly to prevent system disruptions.

Advanced Features

Some Double Regulating Valves come with advanced features to enhance their functionality:

- Pressure Independent Control Valves (PICVs): These valves maintain constant flow rates regardless of pressure changes in the system, simplifying control and improving reliability.

- Digital Controls: Modern DRVs may include digital controls for easier and more precise adjustments, enhancing

By integrating Double Regulating Valves into HVAC systems, operators can achieve improved efficiency, reliability, and comfort while also benefiting from reduced operational costs and a smaller environmental footprint.

Double Regulating Valves in Plumbing

Role of Double Regulating Valves in Plumbing Systems

Double Regulating Valves (DRVs) are crucial in modern plumbing systems, helping maintain consistent water flow and pressure. They play a critical role in ensuring system balance, providing users with a stable and comfortable water supply.

Key Functions in Plumbing

Flow Control and Stability

DRVs regulate the flow of water through plumbing systems by adjusting the valve opening. This precise control ensures a consistent flow rate, which is vital for maintaining stable water temperatures and pressures, especially in buildings where multiple water outlets are used simultaneously.

Pressure Management

One of the main benefits of using DRVs in plumbing is their ability to manage pressure surges. Sudden changes in water demand, such as flushing a toilet or using a washing machine, can cause significant pressure variations. DRVs absorb these surges, protecting the plumbing system from damage and maintaining a steady water supply.

Applications in Plumbing Systems

Domestic Hot Water Systems

At home, DRVs are often used in hot water systems to keep temperatures consistent. They ensure that water remains at a stable temperature, even when other fixtures in the house are used. This provides comfort and prevents the risk of scalding or cold shocks.

Multi-Story Buildings

In multi-story buildings, maintaining consistent water pressure across all floors can be challenging. DRVs help balance the water flow between different levels, ensuring that all floors receive an adequate and consistent water supply. This is crucial for maintaining the performance and comfort of the plumbing system in high-rise buildings.

Commercial Plumbing

In commercial buildings, such as hotels and office complexes, DRVs play a vital role in managing the water supply to various fixtures and appliances. They help maintain consistent water pressure and flow rates, ensuring the smooth operation of plumbing systems and enhancing user experience.

Advantages of Using Double Regulating Valves in Plumbing

Enhanced Comfort

DRVs enhance user comfort in both residential and commercial settings by maintaining stable water flow and pressure, ensuring a reliable water supply without unexpected changes.

Energy Efficiency

DRVs contribute to energy efficiency by optimizing the flow of hot water systems. By maintaining the desired flow rates and preventing wastage, they help reduce energy consumption and operational costs.

System Protection

DRVs protect plumbing systems from damage caused by pressure surges and fluctuations. By managing these variations effectively, they extend the lifespan of the plumbing components and reduce the need for frequent repairs.

Installation Considerations

Proper Placement

When installing DRVs, it’s important to place them at strategic points in the plumbing system where flow and pressure need to be controlled. This ensures optimal performance and effectiveness.

Regular Maintenance

To ensure that DRVs function correctly, regular maintenance is essential. Periodic checks and adjustments help maintain their performance and prevent potential issues.

By integrating Double Regulating Valves into plumbing systems, users can achieve greater comfort, efficiency, and system longevity, making them a valuable addition to any modern plumbing setup.

Benefits of Using Double Regulating Valves

Double Regulating Valves (DRVs) offer precise control over fluid flow in systems, allowing operators to set exact flow rates tailored to the system’s needs. DRVs are instrumental in managing both flow and pressure within fluid systems. They absorb and mitigate pressure surges caused by sudden changes in demand, stabilizing variations and protecting the system from potential damage, ensuring smooth operation.

By maintaining required flow rates, DRVs optimize water circulation, contributing significantly to energy savings. In multi-branch systems, DRVs help balance flow across different branches, ensuring each section receives the correct amount of fluid, reducing energy consumption and improving system efficiency.

In HVAC systems, DRVs ensure consistent water flow, which is crucial for maintaining stable indoor temperatures and improving

DRVs often feature locking mechanisms that allow settings to be easily retrieved after maintenance work. This design simplifies the process of isolating sections of a system for repairs without disrupting

DRVs are versatile and can be used in a variety of applications, including HVAC, plumbing, and industrial systems. Their ability to provide precise flow control and pressure management makes them suitable for a wide range of fluid control scenarios. This versatility ensures that DRVs can meet the needs of different systems, regardless of their complexity or specific requirements.

Step-by-Step Installation Guide

Planning and Selection

Before installing a Double Regulating Valve (DRV), it’s important to plan and select the right valve for your system. Assess the system’s pressure and flow requirements to choose between a Variable Orifice DRV (VODRV) or a Fixed Orifice DRV (FODRV), depending on the system’s stability and load variations. Ensure you have the necessary tools, such as wrenches, screwdrivers, pressure gauges, and flow meters.

Installation Steps

Position the Valve

Identify a suitable location on the pipeline where the DRV will be installed, ensuring it is accessible for future maintenance. Install isolation valves on both sides of the DRV for easy maintenance and adjustments without shutting down the entire system.

Mount the Valve

Align the DRV with the pipeline to ensure proper flow direction, indicated by an arrow on most DRVs. Secure the valve to the pipeline using the proper fittings. Ensure the connections are tight enough to prevent leaks, but avoid over-tightening to prevent damage.

Initial Setup

Set the valve opening using the handwheel based on preliminary calculations or system design specifications. Lock the handwheel in place to maintain the setting during the commissioning phase.

Commissioning

Balance the System

Perform a balancing procedure using pressure test points or flow meters to measure the flow rate through the DRV. Adjust the valve incrementally to achieve the required flow rate as per the system’s design. Verify the flow balance across different branches of the system to ensure even distribution, making necessary adjustments to other DRVs if required.

Final Adjustments

Fine-tune the valve settings to achieve precise flow control, ensuring that the flow rate matches the system’s operational requirements. Lock the handwheel again after making the final adjustments to secure the settings.

Maintenance and Troubleshooting

Regular Inspection

Regularly inspect the valve for wear, damage, or leaks, and promptly address any issues to prevent system disruptions. Clean the valve components and apply lubrication as needed to ensure smooth operation.

Troubleshooting

Identify flow imbalances or performance issues within the system using diagnostic tools, and adjust the DRV settings as necessary to correct these imbalances. Replace worn or damaged parts to maintain optimal functionality.

Selecting the Appropriate Valve for Different Applications

Understanding the System Requirements

Before selecting a Double Regulating Valve (DRV), it’s essential to understand the specific requirements of your system. You need to know the system’s pressure, flow requirements, the type of fluid being controlled, and the operating conditions. Accurately assessing these factors ensures that the chosen valve will perform effectively and efficiently.

Identifying the Type of Double Regulating Valve

Fixed Orifice Double Regulating Valves (FODRVs)

Fixed Orifice DRVs maintain a constant flow rate based on the orifice size and pressure differential. These valves are ideal for systems that have stable flow demands and do not require frequent adjustments. Their simplicity and reliability make them suitable for applications where precise and consistent flow control is needed.

Variable Orifice Double Regulating Valves (VODRVs)

Variable Orifice DRVs allow for adjustments in the flow rate by changing the orifice size. These valves offer flexibility. They are ideal for dynamic systems where load conditions fluctuate. This makes them suitable for systems with varying loads, where the flow rate needs to be adjusted to match changing demand conditions.

Pressure Independent Control Valves (PICVs)

Pressure Independent Control Valves combine balancing and control functions, ensuring constant flow rates regardless of system pressure changes. These valves are highly efficient for dynamic systems with fluctuating pressure conditions, providing precise control and simplifying system management.

Considering Flow Control Requirements

Determine if your system requires a fixed or variable flow rate. For applications with consistent flow demands, a Fixed Orifice DRV may be sufficient. However, if your system experiences varying loads, a Variable Orifice DRV or a PICV might be more appropriate. Understanding your flow control needs ensures you choose the best valve for your system.

Evaluating Pressure Management Needs

Consider whether your system needs to handle pressure variations or maintain constant flow rates under different pressures. PICVs are particularly useful in systems where pressure conditions change frequently, as they can maintain consistent flow rates. For systems with stable pressure, Fixed or Variable Orifice DRVs might be adequate.

Installation and Maintenance Considerations

Choose a valve designed for easy installation and maintenance, including features like isolation ball valves on both upstream and downstream sides to facilitate maintenance without system disruption. Additionally, select valves made from durable materials like brass or stainless steel to ensure long-lasting performance.

Material and Build Quality

Selecting a valve made from high-quality materials is crucial for ensuring durability and reliability. Brass and stainless steel are common materials that offer excellent resistance to corrosion and wear. The build quality of the valve should also be considered, as it impacts the valve’s performance and longevity.

Application-Specific Selection

HVAC Systems

In HVAC systems, particularly in fan coils and air handling units, precise control over water flow and pressure is necessary for efficient heating and cooling operations. DRVs should be selected based on the specific needs of the HVAC system, ensuring optimal performance and energy efficiency.

Plumbing Systems

For plumbing systems, DRVs are used to manage and maintain flow and pressure, ensuring stable water temperature and preventing fluctuations in both chilled water and hot water systems. The selected valve should provide reliable performance to enhance user comfort and system reliability.

Industrial Heating and Cooling

In industrial settings, DRVs are used for balancing high, medium, and low-temperature water systems. The valve should be capable of handling the specific temperature and pressure conditions of the industrial application, ensuring consistent performance and efficiency.

Frequently Asked Questions

Below are answers to some frequently asked questions:

How does a double regulating valve work?

A double regulating valve (DRV) works by modulating water flow through an adjustable mechanism, typically operated manually with a handwheel. This mechanism can be opened or closed to control the volume of water passing through the system. DRVs are designed to provide precise control over the flow rate, which is crucial for maintaining desired conditions in systems with varying demands.

Key features of DRVs include their adjustability, which allows for fine-tuning the flow rate, and their isolation capability, which enables sections of the system to be shut off for maintenance without disrupting the entire operation.

What are the main applications of double regulating valves?

Double Regulating Valves (DRVs) are mainly used in systems where precise control of water flow and pressure is essential. Their primary applications include HVAC systems, where they balance water flow in heating and cooling circuits to maintain comfort levels and operational efficiency. DRVs are also crucial in industrial heating systems, ensuring consistent process conditions which are vital for product quality and system longevity. In commercial buildings, these valves help manage water flow and temperature, reducing energy waste and maintenance costs. Additionally, DRVs are used in domestic hot water systems to maintain consistent water temperatures and in ring main piping circuits for system balancing and commissioning.

How do I select the appropriate double regulating valve for my application?

To select the appropriate double regulating valve (DRV) for your application, begin by defining your system’s requirements. Determine if the valve will be used for heating, cooling, or both, and if precise pressure control is necessary. Identify the desired flow rate and pressure drop that the valve needs to manage.

Next, choose between Variable Orifice Double Regulating Valves (VODRVs) and Fixed Orifice Double Regulating Valves (FODRVs). VODRVs are suitable for applications needing adjustable flow rates, while FODRVs provide higher accuracy and are ideal for applications requiring precise flow measurement.

Consider the installation space and ensure the valve fits within the available area, checking if the valve allows bi-directional flow or has specific flow direction requirements. Evaluate the material and durability; valves made from dezincification resistant brass (DZR) or stainless steel are preferred for longevity.

Lastly, consult manufacturer data to match the valve specifications to your system requirements and verify compatibility with other components. Ensure proper installation and testing to confirm the valve’s performance under operational conditions.

What are the benefits of using double regulating valves in HVAC systems?

Double Regulating Valves (DRVs) offer several benefits when used in HVAC systems. They ensure consistent temperature maintenance by regulating water flow to all areas of a building, which enhances occupant comfort and system performance. DRVs contribute to energy efficiency and cost savings by providing precise flow control and reducing energy waste, thus lowering operational costs. They also improve system reliability by balancing water flow, preventing issues such as water hammers that can damage pipes and equipment, thereby reducing maintenance needs. Additionally, DRVs adapt to variable loads without manual adjustments, making them versatile for different HVAC applications. Their built-in flow measurement capabilities simplify maintenance and installation, streamlining system design.

Can double regulating valves be used in plumbing systems?

Yes, double regulating valves (DRVs) can be used in plumbing systems. They are essential for controlling water flow and pressure, ensuring consistent performance and efficiency. In domestic hot water systems, DRVs help maintain stable water temperature and pressure, enhancing user comfort. Additionally, they are used in boiler systems to regulate hot water flow, preventing overheating or underheating. DRVs provide isolation capabilities, allowing for maintenance without disrupting the pre-set flow rate. Their versatility and precise control make them suitable for various plumbing applications, contributing to overall system reliability and longevity.

What are the steps for installing a double regulating valve?

Installing a double regulating valve involves several systematic steps to ensure proper function and flow regulation. Begin by inspecting the valve for any damage and ensuring it is clean. Select a suitable location for the valve that allows easy access for operation and maintenance. Confirm the flow direction arrow on the valve body matches the piping flow direction. The valve can be installed in either a horizontal or vertical orientation, but a vertical upright position is recommended.

Prepare the pipes by ensuring adequate straight lengths upstream (5 diameters) and downstream (2 diameters) for accurate flow measurement. Align the valve flanges with the piping to avoid stress on the valve body and tighten the bolts in a crosswise pattern to ensure even pressure and a good seal.

After installation, conduct a pressure test to check for leaks. Adjust the valve to set the desired flow rate using the handwheel and refer to the indicator that shows the valve’s position. Utilize the test points on the valve for measuring differential pressure and calculating flow rates during commissioning. Following these steps will help ensure your double regulating valve is installed correctly and functions effectively.