What makes carbon steel the backbone of countless engineering marvels? The answer lies in its versatility and robust performance, encapsulated perfectly in the SAE J403 standard. Delving into the intricate world of SAE J403, this article aims to unravel the complex chemical composition and mechanical properties that make this carbon steel a cornerstone in various industries. From its essential role in automotive manufacturing to its applications in construction and general engineering, we’ll explore how SAE J403 stands out among other steel grades. Join us as we dissect the elements that contribute to its strength and flexibility, and discover why adherence to these standards is crucial for ensuring quality and reliability in your projects. Ready to delve deeper into the fascinating realm of SAE J403 and understand its pivotal role in modern engineering? Let’s get started.

Introduction to SAE J403 and Standards Compliance

Overview of SAE J403 Standard

SAE J403 is a key standard developed by the Society of Automotive Engineers (SAE) that specifies the chemical composition requirements for various grades of carbon steel. This standard is essential for ensuring the consistency and quality of carbon steels used across multiple industries. Initially developed to meet the demands of the automotive industry, SAE J403 now influences sectors such as construction, oil and gas, and general engineering.

Importance in the Manufacturing and Engineering Industries

This standard provides a reliable framework for specifying the chemical composition of carbon steels, which in turn affects their mechanical properties like hardness, strength, and ductility. By adhering to SAE J403, manufacturers can ensure their products meet necessary performance criteria and are suitable for their intended applications. Standardization also facilitates interoperability and compatibility between components produced by different manufacturers, streamlining production processes and reducing the risk of material failure.

Overview of SAE Standards and Their Significance

SAE standards, including J403, are crucial in the automotive and engineering industries because they reflect the latest technological advancements and industry needs. Developed through a rigorous process involving industry experts, these standards ensure quality, safety, and innovation. SAE standards cover a wide range of materials and specifications, providing a comprehensive framework that supports various engineering applications and international collaboration.

Comparison of SAE J403 with ASTM Standards

While SAE J403 focuses on the chemical composition of carbon steels, ASTM standards often specify both chemical composition and mechanical properties, such as tensile strength and yield strength. This distinction allows SAE J403 to offer greater flexibility in applications where specific mechanical properties are not as critical, whereas ASTM standards provide a more complete specification for applications requiring precise performance characteristics.

Importance of Compliance in Industry Applications

Compliance with SAE J403 ensures the safety, reliability, and performance of engineering products by maintaining quality control and meeting regulatory requirements. Adhering to these standards helps manufacturers reduce variability in material properties, meet regulatory requirements, and ensure the longevity and durability of components and structures. In industries such as automotive, construction, and oil and gas, where material failure can have catastrophic consequences, compliance with standards like SAE J403 is essential for mitigating risks.

Chemical Composition of SAE J403

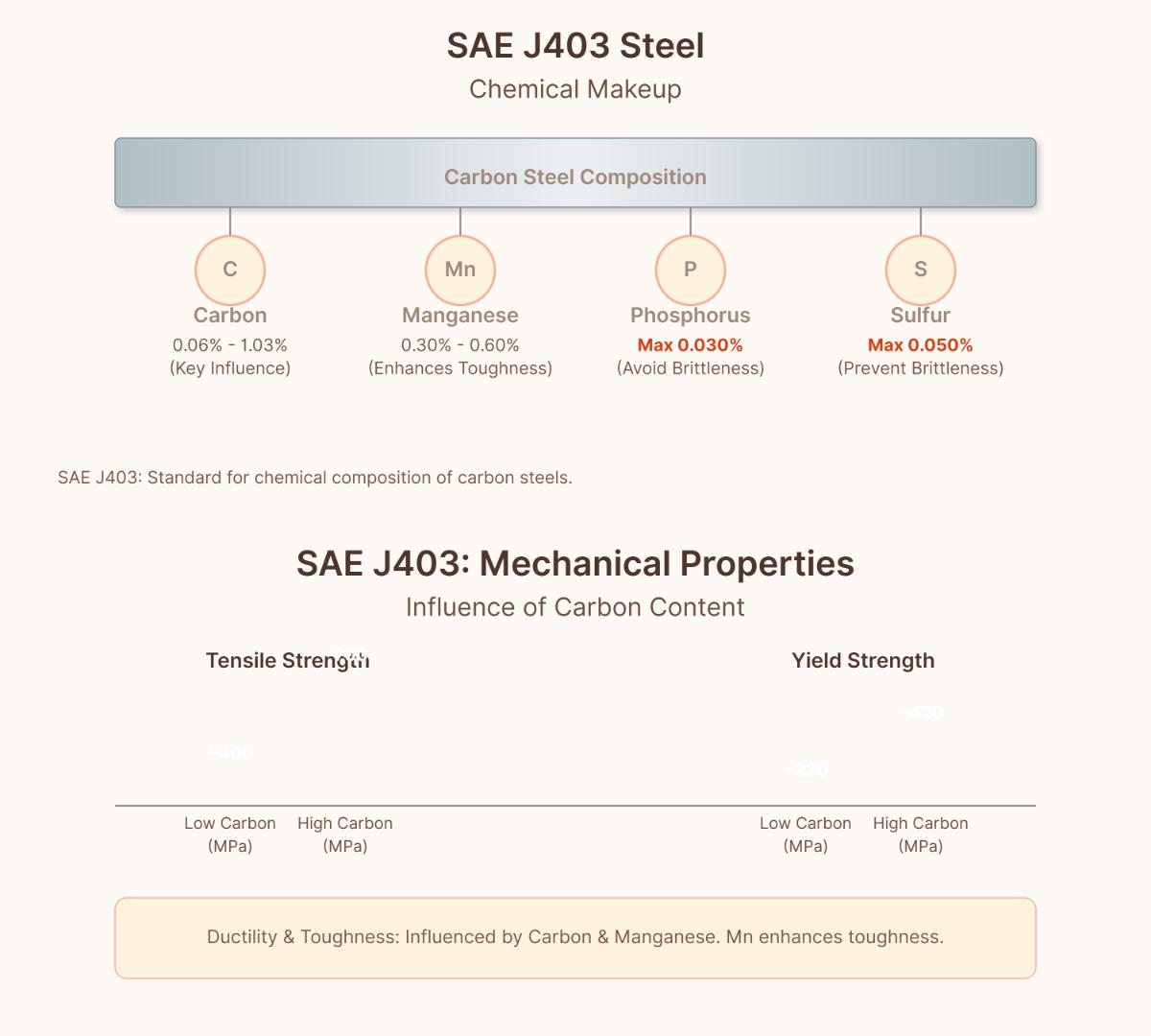

Detailed Breakdown of Chemical Elements

SAE J403 carbon steel has a detailed chemical composition designed to achieve specific mechanical properties and performance. The standard outlines permissible ranges for various elements, ensuring consistency across different grades.

Carbon (C)

Carbon is a fundamental element in SAE J403 steels, significantly influencing their mechanical properties. Depending on the grade, the carbon content typically ranges from 0.06% to 1.03%. Higher carbon levels increase hardness and tensile strength but reduce ductility. For instance, SAE 1005 has around 0.06% carbon, making it more ductile and easier to form, while SAE 1095, with up to 1.03% carbon, is much harder and stronger but less ductile.

Manganese (Mn)

Manganese, usually present in amounts ranging from 0.25% to 0.60%, enhances the steel’s tensile strength and wear resistance. It also improves hardness and toughness, making the steel suitable for high-strength applications.

Phosphorus (P)

Phosphorus is typically kept below 0.040% to avoid brittleness while slightly improving the steel’s strength.

Sulfur (S)

Sulfur content is generally limited to below 0.050% to preserve ductility and prevent brittleness. While sulfur can improve machinability, excessive amounts can lead to brittleness at high temperatures.

Influence of Chemical Composition on Material Properties

The specific combination and concentration of elements in SAE J403 steels determine their mechanical and physical properties. The interplay between carbon, manganese, phosphorus, and sulfur results in a material that can be tailored for various applications through precise control of its chemical makeup.

Comparison with Other Carbon Steels

SAE J403 steels are often compared to other carbon steel standards to understand their unique properties and applications. For instance, compared to ASTM A36, which is a widely used structural steel, SAE J403 steels offer a broader range of carbon contents, allowing for more specialized applications. ASTM A36 typically has a maximum carbon content of 0.26%, making it more uniform but less versatile compared to the diverse grades within SAE J403.

Specific Grades and Their Composition

SAE J403 encompasses several grades, each defined by its distinct chemical composition. Here are a few examples:

- SAE 1005 (G10050): Contains approximately 0.06% carbon and 0.35% manganese, with phosphorus and sulfur each limited to 0.040% and 0.050% respectively. This grade is highly ductile and used in applications requiring extensive forming.

- SAE 1006 (G10060): Features 0.08% carbon and 0.25–0.40% manganese, making it slightly harder than SAE 1005 while retaining good ductility.

- SAE 1008 (G10080): With 0.10% carbon and 0.30–0.50% manganese, this grade offers a balance of ductility and strength, suitable for moderate forming applications.

- SAE 1009 (G10090): Contains 0.15% carbon and 0.60% manganese, providing higher strength and hardness, making it suitable for more demanding applications.

- SAE 1095 (G10950): This high carbon grade, with 0.90–1.03% carbon and 0.30–0.50% manganese, is extremely hard and strong, ideal for applications requiring high wear resistance.

Each grade within SAE J403 is formulated to meet specific needs, allowing engineers and manufacturers to select the most appropriate material for their applications. The careful balance of elements ensures that SAE J403 steels provide reliable performance across a wide range of industrial uses.

Mechanical Properties of SAE J403

Key Mechanical Properties of SAE J403

SAE J403 steel is renowned for its robust mechanical properties, which are crucial for its performance in various high-demand applications. These properties are primarily influenced by the steel’s chemical composition and heat treatment processes.

Tensile Strength

Tensile strength is a critical mechanical property that measures the maximum stress the steel can withstand when stretched before breaking. For SAE J403 steel, tensile strength varies significantly across different grades:

- Lower Carbon Grades: These typically exhibit tensile strengths around 400 MPa.

- Higher Carbon Grades: Higher carbon grades can achieve tensile strengths as high as 700 MPa.

The variability in tensile strength allows for the selection of specific grades based on the required strength for different applications, making SAE J403 versatile in its use.

Yield Strength

Yield strength indicates the stress at which steel begins to deform plastically. This property is vital for ensuring that components maintain their shape under operational stress. Lower carbon grades have yield strengths starting at approximately 220 MPa, while higher carbon grades can reach around 420 MPa.

Understanding yield strength is essential for applications where maintaining structural integrity under load is critical.

Hardness and Ductility

The steel’s carbon content significantly impacts the balance between hardness and ductility:

- Higher Carbon Content: Generally increases hardness and tensile strength but may reduce ductility.

- Manganese: Enhances toughness and wear resistance.

- Phosphorus and Sulfur: Controlled levels ensure the steel remains ductile and resistant to brittleness.

This balance is crucial for applications requiring both durability and the ability to withstand deformation without cracking.

Influence of Chemical Composition

The mechanical properties of SAE J403 steel are closely tied to its chemical composition:

- Carbon Content: Higher carbon levels increase strength and hardness but can decrease ductility.

- Manganese Content: Critical for enhancing toughness and wear resistance.

- Phosphorus and Sulfur: These elements are carefully controlled to maintain ductility and prevent brittleness.

Precisely controlling these elements allows SAE J403 steel to be tailored for specific applications.

Heat Treatment and Performance

Heat treatments like annealing, normalizing, hardening, and quenching and tempering (Q&T) are essential for improving the mechanical properties of SAE J403 steel. These processes can significantly enhance:

- Strength

- Ductility

- Resistance to Fatigue

Heat treatment ensures the steel’s suitability for demanding applications, enhancing its mechanical properties such as strength, toughness, and hardness.

Challenges and Considerations

Several challenges and considerations must be taken into account when working with SAE J403 steel:

- Variability in Chemical Composition: The range of carbon content requires careful selection to ensure the chosen grade meets specific application needs.

- Welding Challenges: Higher carbon content or thicker sections can increase the risk of cracking during welding. Techniques such as preheating and post-weld heat treatment are often necessary.

- Machinability and Formability: While generally good, these properties can decrease with higher carbon content, necessitating appropriate tooling and machining parameters.

Applications

Due to its balanced mechanical properties, SAE J403 steel is used in high-performance components across various industries, including:

- Automotive: Components requiring high tensile strength and impact resistance.

- Construction: Structural elements where durability and reliability are paramount.

- General Engineering: Machinery components and other applications where balanced mechanical properties are crucial.

SAE J403 steel’s versatility and robust mechanical properties make it ideal for applications requiring high strength, impact resistance, and fatigue properties.

Applications and Uses of SAE J403 Carbon Steel

Common Industries Using SAE J403

SAE J403 carbon steel is highly valued across several industries due to its adaptable properties and reliable performance. Key industries that commonly utilize SAE J403 carbon steel include:

Automotive Industry

The automotive industry extensively uses SAE J403 carbon steel for its excellent balance of strength, ductility, and machinability. Key applications include:

- Fasteners and Bolts: These components require high tensile strength and durability to withstand operational stresses in vehicles.

- Structural Parts: Chassis and frame components benefit from the high strength and impact resistance offered by SAE J403.

- Engine Components: Crankshafts, connecting rods, and other engine parts use this steel for its wear resistance and ability to handle high loads.

Construction and Building

In construction, SAE J403 carbon steel is favored for its robustness and versatility. Typical applications include:

- Structural Beams and Columns, and Reinforcement Bars (Rebar): The steel’s strength and ductility make it ideal for load-bearing structures and provide additional tensile strength in concrete.

- Pipes and Tubing: Utilized in plumbing and HVAC systems due to its durability and resistance to deformation under pressure.

General Engineering and Machinery

SAE J403 carbon steel is also prevalent in general engineering and machinery due to its machinability and reliability. Common uses include:

- Valves and Pump Components: These parts need to withstand high pressure and wear, making SAE J403 an ideal choice.

- Industrial Fasteners: Bolts, nuts, and screws made from SAE J403 ensure secure and lasting connections in machinery.

- Tools and Dies: The steel’s hardness and toughness make it suitable for manufacturing durable tools and die sets.

Typical Applications in Manufacturing and Construction

SAE J403 carbon steel’s properties make it suitable for a wide range of manufacturing and construction applications:

Manufacturing Processes

- Stamping and Forming: Lower carbon grades, such as SAE 1005 and 1006, are ideal for stamping and forming due to their excellent ductility.

- Machining: Higher carbon grades, like SAE 1095, are used for parts that require high hardness and wear resistance, making them suitable for machining into precision components.

Construction Applications

- Bridges and Buildings: The steel’s high tensile strength and durability are essential for constructing bridges, high-rise buildings, and other infrastructure projects.

- Road Construction: Used in the production of guardrails, barriers, and other safety features due to its impact resistance and strength.

Case Studies of SAE J403 in Real-World Scenarios

Automotive Fasteners

In the automotive industry, a major manufacturer adopted SAE J403 carbon steel for producing high-strength fasteners. The switch resulted in improved performance and durability of the fasteners, reducing maintenance costs and downtime. The material’s consistent quality and machinability allowed for efficient production processes, enhancing overall productivity and ensuring a reliable supply chain.

Structural Components in Construction

A construction company utilized SAE J403 steel for the structural framework of a large commercial building. The steel’s high tensile strength and ductility ensured the building met stringent safety standards while allowing for design flexibility. The project’s success demonstrated the material’s suitability for demanding construction applications.

Case Studies Focusing on Sustainability and Material Efficiency

Eco-Friendly Manufacturing

A manufacturing firm focused on reducing its carbon footprint by optimizing the use of SAE J403 carbon steel. By using precision cutting and forming techniques, the company minimized waste and improved material efficiency. The steel’s adaptability to various heat treatments also allowed for energy-efficient processing, contributing to the firm’s sustainability goals.

Recyclability in Construction

In a sustainable construction initiative, SAE J403 carbon steel was chosen for its recyclability. After the demolition of an old structure, the steel components were recycled and reused in new construction projects. This practice not only reduced environmental impact but also provided cost savings by minimizing the need for new raw materials.

SAE J403 carbon steel’s versatility and performance characteristics make it an indispensable material in multiple industries, supporting a wide array of applications from automotive components to construction projects. Its adaptability to different processing techniques and ability to meet various performance criteria ensure its continued relevance and utility in modern engineering and manufacturing.

Sustainability and Material Efficiency

Environmental Impact of SAE J403 Production and Usage

The production and use of SAE J403 carbon steel have notable environmental implications. The steel industry is traditionally known for its high energy consumption and carbon emissions, but advancements in technology and practices are helping to mitigate these impacts.

Energy Consumption

Producing SAE J403 steel involves processes like smelting, casting, and rolling, which are energy-intensive. Efforts to reduce energy consumption include using electric arc furnaces (EAFs) instead of traditional blast furnaces. EAFs are more energy-efficient and can utilize scrap steel, reducing the need for raw material extraction and lowering the overall carbon footprint of steel production.

Carbon Emissions

Carbon emissions are a significant concern in steel production, and initiatives to reduce these emissions involve:

- Switching to Cleaner Energy Sources: Utilizing renewable energy sources such as wind, solar, and hydroelectric power in steel production facilities.

- Carbon Capture and Storage (CCS): Using technologies to capture and store carbon dioxide emissions or repurpose them in other industries.

Material Efficiency in Manufacturing Processes

Maximizing material efficiency in manufacturing helps minimize waste and optimize resource use. SAE J403 steel’s adaptability and machinability play a significant role in enhancing material efficiency.

Precision Manufacturing

Precision manufacturing techniques, such as computer numerical control (CNC) machining and additive manufacturing (3D printing), allow for the precise shaping and forming of SAE J403 steel components. These techniques reduce material wastage by ensuring that only the necessary amount of steel is used.

Recycling and Reusability

SAE J403 steel is highly recyclable, which significantly contributes to material efficiency. Recycling steel not only conserves natural resources but also requires less energy compared to producing new steel. The ability to recycle and reuse steel components helps in reducing the overall environmental impact, including lowering greenhouse gas emissions and minimizing waste.

Sustainable Practices in the Use of SAE J403

Adopting sustainable practices in the use of SAE J403 steel can lead to significant environmental and economic benefits. These practices include:

Life Cycle Assessment (LCA)

Conducting life cycle assessments helps in understanding the environmental impact of steel products from production to disposal. This comprehensive analysis aids in identifying areas for improvement and implementing more sustainable practices.

Design for Sustainability

Designing products with sustainability in mind involves:

- Optimizing Material Use: Ensuring that designs use the least amount of material necessary to achieve the desired strength and functionality.

- Facilitating Recycling: Designing components that are easy to disassemble and recycle at the end of their life cycle.

Sustainable Sourcing

Sourcing raw materials responsibly is essential for reducing the environmental footprint. This includes:

- Using Recycled Materials: Incorporating recycled steel in production to reduce the need for virgin raw materials.

- Certifying Suppliers: Working with suppliers who adhere to sustainable practices and environmental standards.

Cost-Effectiveness and Economic Benefits

The cost-effectiveness of SAE J403 steel is a crucial factor in its widespread adoption. The economic benefits include:

Lower Production Costs

Carbon steels like SAE J403 are more affordable than alloy steels, making them a preferred choice due to their cost advantage and excellent mechanical properties.

Reduced Waste

Efficient material use and recycling practices lead to reduced waste, translating to cost savings for manufacturers. By optimizing production processes and minimizing scrap, companies can lower their material costs and improve profitability.

Adaptability to Heat Treatment

SAE J403 steel’s ability to undergo various heat treatments allows for tailored properties to suit specific applications. This adaptability enhances its versatility without requiring significant material changes or additional resources.

Heat Treatment Processes

Common heat treatment processes include:

- Annealing: Enhances ductility and reduces hardness, making the steel easier to machine.

- Quenching and Tempering: Increases strength and hardness, suitable for high-stress applications.

The ability to modify the steel’s properties through heat treatment ensures that the material can meet diverse performance requirements, contributing to its sustainability and efficiency in various applications.

Exploring Alternatives and Comparisons

Comparative Analysis with Other Steel Grades

Knowing how SAE J403 differs from other standards helps engineers and manufacturers make better choices.

Comparison with ASTM A36

ASTM A36, with up to 0.26% carbon, is less hard and strong than some SAE J403 grades, but it offers better weldability and formability. ASTM A36 is typically used in structural applications where uniformity and ease of welding are prioritized.

- Carbon Content: ASTM A36 has a maximum of 0.26%, whereas SAE J403 grades can range from 0.06% to 1.03%.

- Mechanical Properties: ASTM A36 offers a tensile strength of approximately 400-550 MPa, comparable to lower carbon grades of SAE J403 but less than higher carbon grades.

- Applications: ASTM A36 is preferred for structural components like bridges and buildings, while SAE J403 is used in automotive, machinery, and more specialized applications.

Comparison with SAE J402

SAE J402 covers a broader range of carbon and alloy steels, providing comprehensive specifications for both chemical composition and mechanical properties. This makes SAE J402 more versatile for applications needing specific performance traits.

- Scope: SAE J402 includes both carbon and alloy steels, whereas SAE J403 focuses solely on carbon steels.

- Flexibility: SAE J402’s broader designation system allows for more precise tailoring of material properties to meet specific needs.

- Applications: SAE J402 is used in applications requiring high strength and durability, similar to SAE J403, but offers more options for customization through alloying elements.

Comparison with AISI 1045

AISI 1045 is a medium carbon steel known for its balance of strength, toughness, and wear resistance. It is often used in applications where high strength and good machinability are required.

- Carbon Content: AISI 1045 has approximately 0.45% carbon, placing it in the mid-range of SAE J403 grades.

- Mechanical Properties: AISI 1045 offers tensile strength around 570-700 MPa, which is similar to higher carbon grades of SAE J403.

- Applications: AISI 1045 is commonly used in gears, shafts, and axles, similar to some applications of SAE J403.

Pros and Cons of SAE J403 Versus Other Materials

Assessing the pros and cons of SAE J403 steel compared to other materials aids in choosing the right steel grade for specific uses.

Pros of SAE J403

- Versatility: Wide range of grades with varying carbon content allows for tailored mechanical properties.

- Cost-Effectiveness: Generally more affordable than alloy steels, making it a preferred choice for many industries.

- Adaptability: Suitable for various processing methods, including heat treatment, machining, and forming.

Cons of SAE J403

- Weldability: Higher carbon grades can pose challenges in welding due to the risk of cracking.

- Ductility: Increased hardness in higher carbon grades may reduce ductility, limiting their use in applications requiring extensive forming.

- Consistency: Variability in chemical composition requires careful selection to ensure the material meets specific application needs.

Alternatives to SAE J403

- Alloy Steels: Offer enhanced properties such as improved strength, toughness, and resistance to corrosion but at a higher cost.

- Stainless Steels: Provide excellent corrosion resistance and durability, suitable for applications in harsh environments, though they are more expensive and less versatile in mechanical properties compared to SAE J403.

- Aluminum Alloys: Lightweight and corrosion-resistant, ideal for applications where weight reduction is critical, but they lack the high strength and wear resistance of SAE J403.

Decision-Making Guide for Selecting Appropriate Steel Grade

Choosing the right steel grade involves considering mechanical properties, cost, and specific application needs.

Key Considerations

- Mechanical Requirements: Determine the necessary tensile strength, yield strength, hardness, and ductility for the application.

- Processing Methods: Consider the steel’s adaptability to machining, welding, and heat treatment processes.

- Cost Constraints: Evaluate the budget and balance between material performance and cost-effectiveness.

- Environmental Conditions: Assess the need for corrosion resistance, especially in applications exposed to harsh environments.

Application-Specific Recommendations

- Automotive Components: SAE J403 grades with higher carbon content for strength and wear resistance, such as SAE 1095.

- Construction: Lower carbon grades like SAE 1005 or ASTM A36 for structural components requiring good weldability and formability.

- General Engineering: Medium carbon grades like AISI 1045 for gears and shafts requiring a balance of strength and machinability.

By comparing SAE J403 with other steel grades and considering the specific needs of the application, manufacturers and engineers can make informed decisions to ensure optimal material performance and efficiency.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the chemical composition and mechanical properties of SAE J403?

SAE J403 is a standard specifying the chemical composition of carbon steels used in various industries. The chemical composition of SAE J403 steels typically includes:

- Carbon (C): Ranges from 0.06% in low-carbon grades like 1005 to 1.03% in high-carbon grades like 1095.

- Manganese (Mn): Generally between 0.30% and 0.60%, though some grades have higher content.

- Phosphorus (P): Limited to a maximum of 0.030% to avoid brittleness.

- Sulfur (S): Typically kept below 0.050% to prevent brittleness.

The mechanical properties of SAE J403 steels vary depending on the grade and heat treatment. Key properties include:

- Tensile Strength: From around 400 MPa for low-carbon grades to 700 MPa for higher-carbon grades.

- Yield Strength: Approximately 220 MPa for low-carbon grades, increasing to 420 MPa for higher-carbon grades.

- Ductility and Toughness: Influenced by the balance of carbon and manganese, with manganese enhancing toughness and wear resistance.

These properties make SAE J403 steels suitable for applications in automotive components, construction, and general manufacturing, where strength, ductility, and cost-effectiveness are critical.

What are the common uses and applications of SAE J403 carbon steel?

SAE J403 carbon steel is extensively utilized across several key industries due to its favorable combination of strength, ductility, and cost-effectiveness. In the automotive industry, it is employed for manufacturing body panels, structural parts, and fasteners, leveraging its weldability and durability. The construction sector uses SAE J403 for structural elements and reinforcing bars, capitalizing on its strength and resilience. In machinery and equipment manufacturing, this steel is ideal for components such as gears, shafts, and bearings, owing to its wear resistance and machinability. Additionally, general engineering applications benefit from its use in producing valve and pump components, among other parts. The versatility of SAE J403, enhanced by its adaptability to various manufacturing processes like annealing, quenching, and tempering, makes it a preferred choice for many industries.

How does SAE J403 compare to other carbon steel standards?

SAE J403 primarily focuses on specifying the chemical composition of carbon steels, providing guidelines on the percentages of elements like carbon, manganese, phosphorus, and sulfur. This standard contrasts with others, such as ASTM and AISI standards, which often detail both chemical compositions and mechanical properties.

For example, ASTM A36 specifies requirements for mechanical properties such as tensile and yield strength, which are crucial for structural applications. In contrast, SAE J403 allows for flexibility in mechanical properties, enabling manufacturers to tailor these properties through various heat treatments to suit specific applications.

AISI standards, like AISI 4140, focus on alloy steels and include detailed mechanical property requirements, ensuring high strength and toughness for demanding applications. Meanwhile, SAE J403’s focus on chemical composition alone offers versatility and cost-effectiveness, making it widely used in industries like automotive and construction where consistent material performance and ease of machining are essential.

Why is compliance with SAE standards important?

Compliance with SAE standards, such as SAE J403, is essential for several reasons. Firstly, it ensures safety by guaranteeing that materials meet stringent criteria, reducing the risk of failures and accidents. This is particularly important in high-stakes industries like automotive and aerospace. Secondly, adherence to these standards maintains quality control, ensuring consistency and reliability in the manufacturing process. Even minor deviations can lead to significant issues, so compliance is crucial.

Additionally, SAE standards are often referenced in national and international regulations, making compliance necessary for legal market entry and global trade. This facilitates the sale of products across different markets without additional testing or certification. Moreover, these standards support innovation by providing a reliable framework for developing new technologies and materials. Lastly, compliance with SAE standards simplifies the supply chain by ensuring that products meet global expectations, which is vital for manufacturers operating in multiple countries.

What industries most commonly use SAE J403?

SAE J403 steel is commonly used across several key industries due to its versatile properties and well-defined chemical composition. The primary industries that utilize SAE J403 steel include:

- Automotive: In the automotive sector, SAE J403 steel is extensively used for manufacturing body panels, structural parts, and fasteners. Its combination of strength, ductility, and weldability makes it ideal for ensuring safety and performance in various vehicle components.

- Construction: The construction industry leverages the strength and durability of SAE J403 steel for fabricating structural elements, reinforcing bars, and other critical components. These applications require robust mechanical properties to maintain the integrity of buildings and infrastructure.

- Oil and Gas: In the oil and gas industry, SAE J403 steel is used for components that must withstand harsh environmental conditions and stresses, ensuring long-term durability and reliability.

- General Engineering and Machinery: SAE J403 steel is also prevalent in general engineering and machinery applications. Its machinability and wear resistance make it suitable for producing gears, shafts, bearings, and other machinery parts.

These industries benefit from the material’s adaptability, cost-effectiveness, and wide availability, making SAE J403 a preferred choice for various high-performance applications.

How can I determine if SAE J403 is suitable for my application?

To determine if SAE J403 is suitable for your application, you need to consider several factors related to its chemical composition, mechanical properties, and intended use.

First, identify the specific mechanical properties required for your application, such as tensile strength, yield strength, hardness, and ductility. SAE J403 defines the chemical composition of various grades of carbon steel, which directly influences these properties. For example, higher carbon content generally increases tensile strength and hardness but can reduce ductility, making it essential to match the steel grade to your performance requirements.

Next, select an appropriate grade of SAE J403 based on its chemical composition and the application context. For instance, grades like 1006, 1008, and 1045 are used for different purposes—1006 and 1008 are suitable for wire products and sheet metal work due to their lower carbon content, while 1045 is preferred for high-strength components like gears and machine parts.

Additionally, consider the manufacturing processes involved, such as machining, welding, or heat treatment. Higher carbon grades may require specialized handling, including preheating and post-weld heat treatment to prevent issues like cracking.

Lastly, evaluate the cost-effectiveness and availability of the chosen grade. SAE J403 steels are generally cost-effective and widely available, which can influence your project’s budget and timeline.

By thoroughly assessing these aspects—mechanical requirements, grade selection, manufacturing considerations, and cost—you can determine if SAE J403 is suitable for your specific application.