In the world of high-pressure gas cylinders, stainless steel is the unsung hero, quietly ensuring safety and reliability under the most demanding conditions. But what makes stainless steel so indispensable for these critical applications? As you delve into the intricate details of stainless steel selection, you’ll uncover the subtle yet significant differences between 304L and 316L stainless steel variants and how they impact performance. This technical exploration will guide you through the maze of cylinder specifications, standards, and the regulatory landscape, shedding light on how to choose between DOT and TPED compliant cylinders. Whether you’re a seasoned professional or a curious learner, this article will equip you with the knowledge to understand maintenance requirements and safety protocols, ensuring your cylinders operate flawlessly. Are you ready to discover what makes stainless steel the material of choice for high-pressure systems? Let’s dive in.

Introduction to Stainless Steel in High-Pressure Applications

Stainless steel is essential in high-pressure environments because it combines strength, durability, and resistance to corrosion. Its ability to handle pressures over 65,000 psi makes it ideal for environments demanding strength and reliability. The corrosion resistance of stainless steel is vital in applications exposed to moisture or reactive substances, ensuring long-term safety and performance. The presence of elements like chromium and molybdenum in specific grades significantly enhances this resistance, making stainless steel a preferred choice in aggressive settings.

Common Grades Used in High-Pressure Applications

Grades like 304 and 316 are popular due to their balance of cost and performance, with 316 offering extra corrosion resistance thanks to molybdenum. Duplex stainless steel, such as 2205, combines austenitic and ferritic structures, providing higher strength and improved stress-corrosion resistance. This makes it suitable for extreme pressure-temperature cycles found in industrial and energy applications. For ultra-high-pressure or high-temperature environments, specialized alloys like Inconel and 317L are employed, often seen in aerospace and deep-sea storage scenarios.

Design and Manufacturing Considerations

Cold-drawn tubing ensures seamless, strong structures necessary for safety in high-pressure gas storage. This process is crucial for maintaining tight tolerances and structural integrity. Heat treatment enhances the grain structure of stainless steel, preventing cracking under cyclic loading, which is integral to its durability. The wall thickness of stainless steel cylinders directly correlates with their pressure tolerance, with thicker walls offering greater safety by reducing burst risks.

Applications in High-Pressure Systems

Stainless steel is extensively used in industrial gas storage for oxygen, hydrogen, and compressed natural gas (CNG), minimizing leakage risks and ensuring efficient storage. In aerospace and energy sectors, high-grade stainless steel alloys are utilized in fuel tanks and rocket propulsion systems, benefiting from the material’s ability to withstand rapid pressure changes and extreme conditions. The medical and pharmaceutical industries rely on stainless steel cylinders for delivering medical gases, where sterility and reliability are crucial.

Comparative Advantages Over Alternative Materials

Here’s how stainless steel stacks up against brass in high-pressure applications:

| Factor | Stainless Steel | Brass |

|---|---|---|

| Tensile Strength | >65,000 psi |

Material Science Behind Stainless Steel Selection

Corrosion Resistance

Corrosion resistance is a critical factor when selecting stainless steel for high-pressure gas cylinders due to its protective properties. The chromium content in stainless steel forms a passive layer of chromium oxide, shielding the material from corrosion. This feature is particularly vital in environments where cylinders encounter moisture, chemicals, or extreme temperatures. Austenitic stainless steels, such as grades 304 and 316, are known for their outstanding corrosion resistance. Grade 316, with added molybdenum, offers enhanced protection against chlorides and other harsh substances, making it a favored choice for marine and industrial settings.

Mechanical Properties

Strength and Ductility

Strength and ductility are essential mechanical properties for high-pressure gas cylinders. These properties ensure the cylinders can handle the high pressures without deforming or breaking. Austenitic stainless steels provide a well-balanced combination of strength and flexibility, making them ideal for applications requiring durability and adaptability.

Impact Resistance

Impact resistance is also important because the material must absorb energy without cracking in case of accidents or rough handling. Austenitic stainless steels excel in this area due to their excellent toughness, maintaining the integrity and safety of the gas cylinders even under duress.

Physical Properties

Density and Magnetic Characteristics

Stainless steels have a consistent density across different grades, making design calculations straightforward for high-pressure applications. The magnetic properties, however, can vary. Austenitic stainless steels are typically non-magnetic, which is advantageous in environments sensitive to magnetic interference. In contrast, ferritic and martensitic stainless steels are magnetic, which may restrict their use in certain settings.

Fabrication and Welding

Ease of Fabrication

Austenitic and ferritic stainless steels are easier to shape and weld, enabling the creation of complex designs necessary for efficient gas storage. This ease of fabrication reduces manufacturing costs and time, making these grades economically attractive.

Welding Techniques

Utilizing appropriate welding techniques is crucial to preserve the mechanical properties of stainless steel. Processes such as TIG (Tungsten Inert Gas) welding are preferred for their precision and ability to produce high-quality joints, ensuring the material’s integrity is maintained.

Cost and Availability

Economic Considerations

Selecting stainless steel involves balancing performance with cost. Austenitic grades like 304 are popular due to their cost-effectiveness and wide availability. These grades offer a favorable compromise between initial investment and long-term maintenance expenses.

Life Cycle Cost Analysis

Evaluating the life cycle cost of stainless steel is essential in making informed decisions. This includes assessing the initial cost, ongoing maintenance, and expected lifespan of the cylinders. Austenitic stainless steels, with their durability and minimal maintenance needs, often result in a lower total cost over the cylinder’s operational life.

Key Stainless Steel Grades for High-Pressure Applications

Austenitic grades, such as 304 and 316, are commonly selected for their excellent corrosion resistance and formability. While ferritic grades like 430 and 439 are less prevalent in high-pressure applications, they can serve as a cost-effective option in less demanding environments. Martensitic grades, despite their high strength, are generally avoided for high-pressure vessels due to their limited ductility and formability, which can present challenges during manufacturing and application.

Cylinder Specifications and Standards

Stainless steel cylinders are engineered to meet specific requirements that ensure their durability and performance in high-pressure environments. The choice of material, particularly grades like 304 and 316L, is critical due to their exceptional mechanical properties and resistance to corrosion.

Key Material Properties

Stainless steel naturally resists corrosion thanks to its chromium content, which forms a protective layer against reactive elements. This makes it suitable for storing gases that might otherwise react with the material. The mechanical strength of stainless steel allows these cylinders to endure high internal pressures without deforming, ensuring both safety and longevity. Additionally, stainless steel can withstand a wide range of temperatures, making it ideal for applications involving extreme heat or cold.

Cylinder Design Specifications

The design of stainless steel cylinders is meticulously crafted to ensure safety and performance.

Wall Thickness and Pressure Rating

The thickness of a cylinder’s walls determines its ability to handle pressure. Thicker walls mean higher pressure tolerance, essential for environments with extreme pressure demands. Pressure ratings vary, with 304 stainless steel typically rated at 1800 psi and 316L stainless steel capable of handling up to 4350 psig.

Capacity and Size

Cylinders come in various sizes and capacities, from small units for portable use to large ones for industrial applications, offering flexibility to meet diverse needs. This range allows for tailored solutions across different sectors, ensuring the right cylinder is available for each specific application.

Standards and Compliance

Adhering to standards is crucial for the safety and reliability of stainless steel cylinders.

DOT and TPED Standards

DOT and TPED standards ensure that cylinders are safe for transport and use in the U.S. and Europe, covering material quality, design, and testing protocols. DOT standards, such as DOT-3A, regulate the safe transport of high-pressure cylinders in the United States, while TPED provides similar guidelines for the European market.

International Standards

ISO standards promote global safety and compatibility, addressing aspects like manufacturing quality, pressure testing, and labeling. CGA connections standardize valve fittings, ensuring compatibility and facilitating safe handling across various applications.

Specialized Cylinder Features

Stainless steel cylinders can be customized to suit specific application needs. Options such as Sulfinert treatment enhance inertness, crucial for applications requiring minimal contamination like chemical and gas sampling. Additional customization options, including painting, stamping, and neck-rings, allow for personalization according to specific requirements, improving operational efficiency and identification.

Regulatory Landscape for Gas Cylinders

Core Regulatory Standards

OSHA & CGA Compliance

The Occupational Safety and Health Administration (OSHA) and the Compressed Gas Association (CGA) have established strict guidelines to ensure the safe storage, handling, and use of high-pressure gas cylinders. OSHA’s regulation 29 CFR 1910.102 mandates that gas cylinders be stored upright, separated from flammable materials, and equipped with valve protection. This is crucial for preventing accidents and ensuring the cylinders’ structural integrity.

CGA guidelines emphasize the importance of robust valve integrity and leak prevention mechanisms. Given the operational stresses on high-pressure stainless steel cylinders, these guidelines ensure that the materials used can withstand significant pressure without compromising safety. The regulations implicitly require corrosion-resistant materials, such as stainless steel, especially for cylinders storing reactive or high-purity gases. This is to minimize contamination risks and maintain the purity of the stored gases.

Indian Gas Cylinder Rules (2016)

In India, the Gas Cylinder Rules of 2016 stipulate comprehensive requirements for the manufacturing, storage, and handling of gas cylinders. These rules mandate that manufacturers obtain licenses under the Explosives Act, ensuring that only certified and compliant cylinders enter the market. Stainless steel is often specified in these regulations due to its safety certifications and material properties that meet stringent safety standards.

Storage protocols under these rules also dictate that facilities storing large quantities of gas cylinders must be licensed, emphasizing the need for structural stability and fire-resistant environments. This is particularly relevant for stainless steel cylinders, which are preferred for their robustness and ability to withstand high-pressure conditions.

Environmental & Hazardous Waste Directives

Environmental regulations, such as the Hazardous Waste Management Rules of 2016, govern the proper disposal and recycling of gas cylinders. Stainless steel’s durability plays a significant role here, as it reduces the risk of leakage during decommissioning. The Environmental Protection Agency (EPA) guidelines also apply to the production processes of cylinders, promoting pollution control measures that align with stainless steel’s durability and lower environmental impact.

Stainless Steel in High-Pressure Cylinders: Regulatory Alignment

Material Benefits

Stainless steel meets various regulatory requirements due to its superior corrosion resistance, making it suitable for applications involving medical gases and calibration gases. Its ability to minimize particulate shedding ensures compliance with hygiene standards, which is critical in maintaining the purity of gases.

Stainless steel cylinders are designed to withstand pressures exceeding 3,000 PSI, aligning with OSHA’s mechanical integrity mandates. This structural resilience is essential for the safe storage of industrial and refrigerant gases, ensuring that cylinders do not fail under high-pressure conditions.

Fire Safety

Stainless steel’s non-sparking nature enhances fire safety, especially in environments where acetylene and LPG are stored together, aligning with NFPA rules. This reduces the risk of ignition in mixed-storage environments, providing an additional layer of safety.

Emerging Trends (2023–2024)

Leak Prevention Technology

New advancements in leak prevention now integrate IoT sensors with stainless steel cylinders, allowing for real-time pressure monitoring and addressing updated CGA guidelines. This innovation ensures that any potential leaks are detected and managed promptly, enhancing overall safety.

Recycling Mandates

There is a growing emphasis on the recycling of stainless steel cylinders under stricter hazardous waste management rules. Stainless steel’s high scrap value and environmental non-toxicity make it a preferred material for recycling initiatives, promoting sustainable practices in the industry.

Stainless steel’s regulatory advantages, including its durability, inertness, and compliance with evolving safety and environmental standards, continue to make it the material of choice for high-pressure and specialty gas containment.

Applications in Industry

Applications in Industry

Stainless steel’s role in high-pressure gas cylinders is pivotal across various industries due to its unparalleled strength, durability, and resistance to corrosion. This section delves into its applications, highlighting the unique advantages stainless steel offers in different sectors.

Medical and Pharmaceutical Industry

Stainless steel cylinders are essential in the medical and pharmaceutical industries for storing and transporting critical medical gases like oxygen and nitrous oxide. These gases are vital for patient care, requiring a material that ensures both purity and safety. Stainless steel, especially the 316L grade, is preferred for its corrosion resistance and non-reactive properties, preserving the integrity of these gases. Compliance with stringent regulations like DOT-3A ensures these cylinders can operate safely under high pressures, making them reliable in medical settings where safety cannot be compromised.

Industrial Gas Supply and Manufacturing

The industrial sector relies heavily on stainless steel cylinders for gases such as nitrogen, argon, helium, carbon dioxide, and hydrogen. These cylinders are designed to withstand extreme pressures and corrosive environments, essential for demanding processes like welding, chemical manufacturing, and metal fabrication. The robustness of stainless steel prevents cracking or rupturing under high pressures, ensuring operational safety and continuity in industries where failure is not an option.

High-Purity and Specialty Gas Applications

Industries that need ultra-high purity gases, like electronics manufacturing, laboratory research, and semiconductor production, greatly benefit from using stainless steel cylinders. The material’s inert surface minimizes contamination risk, crucial for maintaining gas purity. Moreover, the ease of cleaning and maintenance associated with stainless steel supports consistent gas quality and safety, which are paramount in these precision-demanding sectors.

Transportation and Storage of Reactive Gases

Storing reactive or hazardous gases like oxygen or carbon monoxide is challenging. Stainless steel’s non-reactive nature makes it ideal for safely containing these gases and reducing the risk of chemical reactions or corrosion. This characteristic is vital for maintaining cylinder integrity and ensuring the purity of the stored gases, particularly in environments where safety is paramount.

Key Industrial Advantages of Stainless Steel in High-Pressure Gas Cylinders

- Strength and Pressure Resistance: Stainless steel cylinders, particularly those made from 316L grade, can handle pressures up to 4350 PSIG or higher. This high-pressure tolerance supports a wide range of applications, ensuring safety and reliability in even the most extreme conditions.

- Corrosion Resistance: The resistance to rust and chemical attack enables the use of stainless steel cylinders in harsh, humid, or outdoor environments, where carbon steel might fail. This feature is crucial for industries that require long-term cylinder durability and safety.

- Safety and Compliance: Stainless steel cylinders meet rigorous regulatory standards, such as DOT, TC, ISO, and military specifications. These standards mandate regular inspections and tests, helping industries maintain high safety standards in gas storage and transport.

- Low Maintenance Costs: The inherent durability and corrosion resistance of stainless steel cylinders lead to reduced maintenance frequency and costs. This longevity provides economic benefits over time, despite a higher initial investment.

- Versatility: Stainless steel cylinders can be tailored with various valve types, sizes, and accessories to suit specific industry needs. This customization ranges from small lecture bottles for high-purity gases to large industrial cylinders for bulk gas storage, enhancing their applicability across diverse sectors.

The unique combination of high strength, corrosion resistance, and chemical inertness makes stainless steel the material of choice for high-pressure gas cylinders across multiple industries. Its reliability ensures safe containment of a variety of gases, from reactive to high-purity and industrial gases, while minimizing maintenance and maximizing operational safety.

Maintenance and Safety Protocols

Stainless steel is highly valued for its strength and resistance to corrosion, making it an excellent choice for high-pressure gas cylinders. These attributes not only ensure safety and reliability but also reduce the frequency and severity of maintenance interventions. Additionally, stainless steel’s ability to resist chemical reactions makes it particularly suitable for storing reactive or high-purity gases, which is crucial in medical and industrial applications.

Maintenance Best Practices

Regular Inspections

Implementing a routine inspection schedule is crucial for maintaining the integrity of high-pressure stainless steel cylinders. Visual inspections should be conducted to identify any signs of damage such as dents, scratches, or rust. Ensure labels and markings remain legible for compliance and safe handling. Focus on critical areas like weld points and valve attachments, as these are prone to wear over time.

Leak Detection

Simple methods to detect leaks should be employed to ensure safety. Use soapy water or a special solution to spot leaks, but never use flames due to explosion risks. Regular leak tests are vital to prevent accidental gas release, which can pose significant safety hazards.

Valve and Regulator Care

Valves and regulators require careful maintenance to ensure they function correctly. Keep valves clean and closed when not in use, and always protect them with caps to prevent damage. Regulators should be removed during transport or storage to avoid unnecessary strain and potential damage. Regular checks and maintenance of these components are essential to maintain the cylinder’s safety and operational efficiency.

Testing and Certification

Adhering to regulatory testing and certification requirements is crucial. Hydrostatic testing, which involves pressurizing the cylinder with water to check for leaks and evaluate structural integrity, should be performed every five years in accordance with DOT regulations. Cylinders that exceed their certification dates must be replaced to comply with legal transport and safety standards.

Safety Protocols

Storage Guidelines

Proper storage is paramount for safety. Store cylinders upright in a cool, ventilated area, away from heat sources, and keep incompatible gases, like flammable and oxidizing types, apart.

Handling Procedures

Safe handling procedures are essential to prevent accidents. Cylinders should be moved using appropriate equipment like trolleys or lifts to avoid dragging or dropping. When opening valves, it is critical to do so slowly and stand clear of gauges and outlets to prevent exposure to high-pressure gas releases.

Personal Protective Equipment (PPE) and Training

Employing appropriate PPE and conducting regular training are vital components of a comprehensive safety protocol. Personnel should wear gloves, goggles, and flame-resistant attire when handling gas cylinders. Staff training should cover emergency response procedures for dealing with leaks or ruptures to ensure a quick and effective reaction to potential incidents.

Regulatory Compliance

Compliance with standards set by OSHA, CGA, and NFPA is essential for the safe storage, labeling, and transport of gas cylinders. These regulations guide the implementation of safety measures such as using flashback arrestors and check valves in oxy-fuel systems to prevent explosions, thereby ensuring a secure working environment.

Innovations and Cost Considerations

Recent innovations have led to the development of stainless steel cylinders capable of withstanding pressures up to 60,000 psig, enhancing their reliability in extreme conditions. The non-reactive nature of stainless steel minimizes contamination risks, making these cylinders invaluable in industries requiring high-purity gas storage, such as semiconductor manufacturing and medical applications. Although the initial investment in stainless steel cylinders is higher, their reduced maintenance needs and extended lifespan make them a cost-effective choice over time.

Frequently Asked Questions

Below are answers to some frequently asked questions:

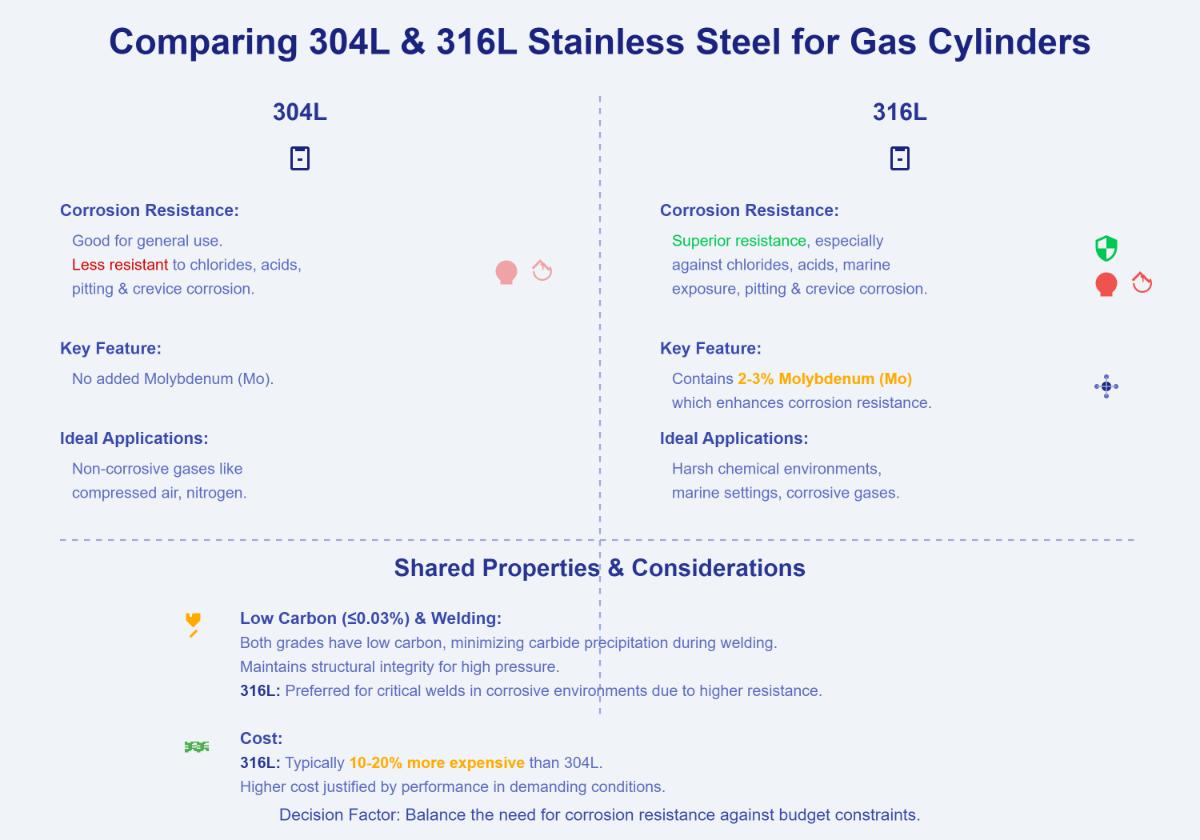

What’s the difference between 304L and 316L stainless steel for gas cylinders?

304L and 316L stainless steels are both commonly used for high-pressure gas cylinders, but they differ primarily in their resistance to corrosion. The key distinction lies in the molybdenum content of 316L, which is 2–3%, enhancing its resistance to pitting and crevice corrosion, particularly in environments containing chlorides, acids, or marine exposure. This makes 316L ideal for cylinders used in harsh chemical or marine applications. In contrast, 304L lacks molybdenum, making it less resistant to such aggressive environments but adequate for general-purpose applications involving non-corrosive gases like compressed air or nitrogen.

Both grades have low carbon content (≤0.03%), which minimizes carbide precipitation during welding, an essential factor for maintaining structural integrity in high-pressure applications. However, 316L is preferred for critical welds in corrosive environments due to its superior corrosion resistance. Economically, 316L is more expensive, typically 10–20% higher in cost, but this is justified by its performance in demanding conditions. Therefore, choosing between these alloys should be based on the specific environmental conditions and cost considerations.

How do I choose between DOT and TPED compliant cylinders?

When choosing between DOT and TPED compliant cylinders for high-pressure gas applications, consider the geographical location of your operations and the regulatory requirements. DOT cylinders, regulated by the U.S. Department of Transportation, are primarily used in the United States and are stamped with markings conforming to 49 CFR 178.35 standards. They are suitable for transportation and handling within the U.S.

On the other hand, TPED cylinders comply with the European Union’s Transportable Pressure Equipment Directive and are marked according to EU regulations, including the ‘pi’ marking. They are intended for use within Europe but can be imported into the U.S. under specific conditions.

Additionally, TPED/UN/ISO cylinders often have higher service pressures, which might be advantageous if your application requires filling high-pressure gases. Both types can be constructed from stainless steel, known for its corrosion resistance and durability. Ultimately, your choice should align with the regional compliance standards and specific pressure requirements of your application.

What maintenance is required for high-pressure stainless steel cylinders?

Maintaining high-pressure stainless steel cylinders is crucial for ensuring safety, efficiency, and longevity. Key maintenance tasks include regular inspections and testing, such as hydrostatic testing, to confirm the cylinder’s integrity and ability to withstand the designated pressure. Corrosion prevention is also important; cylinders should be kept away from electrical wiring, heat sources, and corrosive vapors. Proper handling and storage involve securing cylinders in well-ventilated areas and ensuring they are not near incompatible materials or ignition sources. Employee training is essential to ensure only authorized personnel handle the cylinders. Valve maintenance, including using PTFE paste for proper sealing, is also recommended. By following these guidelines, the performance and safety of high-pressure stainless steel cylinders are significantly enhanced.

What are the key design considerations for high-pressure systems?

When designing high-pressure systems, particularly for stainless steel gas cylinders, several key considerations must be addressed to ensure safety and efficiency. First, the design pressure should exceed the maximum operating pressure by 5-10% to accommodate fluctuations during startup, shutdown, and upset conditions. Material selection is crucial; stainless steel is often preferred due to its durability and resistance to corrosion at high pressures. Thorough stress analysis using techniques like Finite Element Analysis (FEA) is essential to evaluate stress distribution and prevent failure modes such as yielding or fatigue.

Safety features such as safety valves and rupture discs are vital for overpressure protection, allowing excess pressure to be relieved safely. Temperature considerations are also important, as increased temperatures can reduce material strength, necessitating careful thermal management. Additionally, environmental factors like ambient temperature and humidity should be accounted for, as they can impact system performance. By integrating these elements, high-pressure systems can be designed to operate safely and reliably.

How do international compliance standards affect gas cylinder selection?

International compliance standards significantly impact the selection of gas cylinders, particularly those made from stainless steel for high-pressure applications. These standards, developed by organizations such as ISO, set stringent requirements for materials, design, manufacturing, testing, and safety protocols to ensure the reliability and safety of gas cylinders globally. For stainless steel cylinders, compliance with these standards guarantees that the material is suitable in terms of strength, corrosion resistance, and durability, crucial for safely containing high-pressure gases. Standards like ISO 9809 specify manufacturing techniques, ensuring cylinders are free from defects and able to withstand high internal pressures. Moreover, compliance involves rigorous testing, such as hydrostatic testing, to verify cylinder integrity under extreme conditions. Adhering to these standards also facilitates global trade, allowing cylinders to be used across different jurisdictions without modifications, thus ensuring consistent quality and safety. This harmonization supports industry interoperability and ensures that users receive cylinders that meet unified safety benchmarks.

What is the importance of hydrostatic testing for safety?

Hydrostatic testing is crucial for ensuring the safety and reliability of stainless steel high-pressure gas cylinders. This testing method involves filling the cylinder with water and pressurizing it beyond its operational limits to check for leaks, material fatigue, or micro-fractures. By doing so, it identifies hidden defects such as stress cracks or corrosion that could lead to cylinder ruptures under pressure. This non-destructive testing helps prevent accidents during use or transport, safeguarding operators and bystanders from potential high-energy explosions. Furthermore, hydrostatic testing is often a regulatory requirement, with standards mandating regular testing intervals, typically every 3 to 5 years, to maintain compliance. Overall, hydrostatic testing not only ensures the structural integrity and safety of cylinders but also extends their service life by preventing premature retirement due to undetected flaws.