Imagine turning industrial waste into a valuable resource that revolutionizes construction while promoting sustainability. This is the promise of copper slag, a byproduct of copper smelting that is gaining attention for its potential benefits. However, like any material, it comes with its own set of advantages and disadvantages. From enhancing the durability and strength of construction materials to offering cost-effective and environmentally friendly solutions, copper slag presents a compelling case for its use. Yet, it also poses challenges, such as potential health risks and limitations in certain applications. How does it stack up against traditional construction materials, and what should you consider before incorporating it into your projects? Dive into this comprehensive analysis to uncover the full spectrum of copper slag’s potential and pitfalls.

What is Copper Slag?

Definition and Origin

Copper slag is a byproduct created when copper ore is smelted to extract pure copper. During the smelting process, impurities separate from the molten copper. These impurities, primarily iron and silicon oxides, form a layer on top of the molten copper called copper slag.

Production Process

The production of copper slag begins with heating copper ore in a furnace to extremely high temperatures. This causes the copper to melt and the impurities to separate out. Due to their different densities, the lighter impurities rise to the surface, creating the slag layer. After removing the slag from the furnace, it is quickly cooled in water. This rapid cooling process results in the formation of angular granules. Unlike other by-products like steel slag, which cools more slowly, copper slag’s rapid cooling gives it a distinct angular shape.

Common Uses in Various Industries

Abrasive Blasting

Copper slag is widely used in abrasive blasting operations. Its angular shape and high hardness, typically around 6 to 7.5 on the Mohs scale (similar to quartz), make it an effective material for removing coatings, rust, and corrosion from surfaces. Copper slag, with less than 1% free silica content, poses fewer health risks for workers compared to traditional abrasives like sand. Its high bulk density (ranging from 100 to 120 lbs/cu.ft.) means that fewer particles are needed to achieve the same cleaning results as lighter abrasives, leading to reduced consumption and costs.

Construction

In the construction industry, copper slag can be used as an aggregate in concrete. It helps increase the strength of concrete and reduces water absorption. When compared to natural aggregates, copper slag offers an alternative that can make use of an industrial by-product, potentially reducing the demand for virgin materials. Additionally, in road construction, copper slag’s anti-slip properties make it useful, and it can also serve as a filler material.

Advantages of Using Copper Slag

Durability and Strength

Copper slag is exceptionally durable and strong, making it a preferred choice for many industrial applications. With a high density of around 3.4 g/cm³ and a hardness greater than 7 on the Mohs scale, copper slag is robust enough to withstand harsh conditions and repeated use, ensuring long-term performance and cost savings.

Cost-Effectiveness

Copper slag is more affordable than other abrasive materials like garnet, aluminum oxide, steel, and glass. Its angular particles enhance blasting efficiency, leading to faster cleaning times and reduced material consumption. This not only lowers operational costs but also improves the overall productivity of the blasting process.

Environmental Benefits

Recyclability

Copper slag is environmentally friendly because it is a byproduct of copper smelting. Utilizing copper slag helps reduce waste generated by copper production, contributing to more sustainable industrial practices. Its recyclability further enhances its eco-friendly profile, as it can be reused multiple times without losing effectiveness.

Low Silica Content

Another environmental advantage of copper slag is its low free crystalline silica content, typically less than 1%. This makes it a safer alternative to silica-based abrasives, which pose significant health risks, such as silicosis, to workers exposed to silica dust. Using copper slag helps mitigate these health hazards, promoting a safer working environment.

Versatility

Industrial Applications

Copper slag’s versatility is evident in its wide range of industrial applications. It is extensively used in abrasive blasting and surface preparation, where its hard, angular particles effectively remove coatings, rust, and corrosion from surfaces. Additionally, it serves as a substitute for sand in concrete, enhancing the strength and durability of cement-based materials.

Non-Industrial Uses

Beyond industrial applications, copper slag is also used in non-industrial settings. For example, it is a popular infill material for artificial turf due to its stability and antimicrobial properties. This versatility makes copper slag a valuable resource in both industrial and non-industrial contexts.

Waste Reduction and Recycling

Copper slag plays a crucial role in waste reduction and recycling efforts. By repurposing a byproduct of copper smelting, industries can minimize waste and reduce their reliance on virgin materials. This not only conserves natural resources but also aligns with global sustainability goals and environmental regulations. The recycling process of copper slag involves its collection, cleaning, and reprocessing, ensuring that it can be reused efficiently in various applications.

Compliance with Environmental Regulations

Using copper slag helps industries meet strict environmental regulations. Its low silica content and recyclability make it a compliant material in many regions, where regulations mandate the reduction of hazardous waste and the promotion of sustainable practices. By adopting copper slag, companies can meet regulatory requirements while benefiting from its technical and economic advantages.

Disadvantages of Using Copper Slag

Environmental and Health Risks

While copper slag offers many advantages, it also poses substantial environmental and health risks.

Heavy Metal Contamination

Copper slag contains heavy metals such as arsenic, lead, and cadmium. These metals can leach into the soil and water sources, leading to contamination. These toxic elements can seep into the soil and water, causing long – term damage and making cleanup efforts more difficult.

Airborne Dust and Respiratory Issues

Abrasive blasting with copper slag produces dust that can be harmful if inhaled, potentially causing respiratory issues like silicosis. Although it contains less free silica than traditional sand, other harmful particles still pose health risks to workers.

Limited Reusability

Copper slag is generally not reusable after its initial application, particularly in abrasive blasting. This lack of reusability results in significant waste generation. The accumulation of used slag can lead to disposal challenges, increasing the burden on waste management systems and potentially leading to higher disposal costs. Unlike some other materials that can be recycled or repurposed more efficiently, the single – use nature of copper slag limits its sustainability.

Chemical Reactivity

In certain applications, copper slag can exhibit undesirable chemical reactivity. For instance, when used in cement or concrete, the presence of specific elements in the slag can interfere with the hydration process, potentially compromising the integrity and performance of the final product. This necessitates careful selection and testing of copper slag to ensure compatibility with other materials, which can complicate its use and increase costs.

Regulatory and Compliance Challenges

Copper slag is strictly regulated due to the potential release of toxic substances. These regulations can vary significantly by region, adding complexity to its use and disposal. Compliance with these regulations often requires additional testing, documentation, and adherence to strict guidelines, which can increase operational costs and limit the adoption of copper slag in certain areas.

Potential for Air Pollution

Abrasive blasting with copper slag can result in airborne pollutants that exceed occupational exposure limits. These pollutants include not only dust but also other toxic metals that can pose immediate and long – term health risks to workers. Effective dust control measures and personal protective equipment are essential to mitigate these risks, but they also add to the overall cost and complexity of managing an abrasive blasting operation. To ensure the safety and well-being of workers, employers must prioritize rigorous monitoring of air quality, provide regular health check-ups, and enforce strict adherence to safety protocols.

Limited Application Versatility

Although versatile, copper slag isn’t suitable for all applications. Its chemical properties may not fit every concrete or construction project, and its angular shape and high density, while useful for blasting, might not be ideal for other purposes.

Comparing Copper Slag with Other Materials

Comparative Analysis with Traditional Construction Materials

Copper slag, a byproduct of copper refining, is increasingly being compared to traditional construction materials like sand and gravel. Copper slag is lighter, more cost-effective, but may not always be as readily available as sand and gravel. Its low water absorption and high durability make it a strong contender for use in concrete and road construction, offering enhanced anti-slip properties and improved longevity. However, its angular shape may not suit all concrete mixes, especially those needing a smoother finish.

Benefits and Drawbacks in Different Contexts

Abrasive Blasting

When comparing copper slag to other abrasive materials such as silica sand and steel grit, several advantages and disadvantages come to light. Copper slag produces less dust than silica sand, reducing health risks like respiratory issues from inhaling fine particles. Additionally, its hardness and angular shape make it highly effective for surface preparation, requiring less material to achieve desired results. However, unlike steel grit, which can be reused multiple times, copper slag is generally single-use, leading to increased waste and disposal costs.

Infill Material for Artificial Turf

As an infill material for artificial turf, copper slag offers stability and antimicrobial properties, making it a popular choice. Compared to rubber infill, copper slag is less likely to compress over time, maintaining the turf’s integrity. However, in hot climates, copper slag can retain heat, potentially making the surface uncomfortably warm. This heat retention issue makes it less ideal for regions with high temperatures, where other materials like silica sand or rubber may perform better.

Case Studies and Expert Insights

Construction Projects

Several construction projects have demonstrated the effective use of copper slag as an aggregate in concrete. In these case studies, copper slag has been shown to enhance the compressive strength and durability of concrete, making it a viable alternative to natural aggregates. Experts in the construction industry highlight its cost-effectiveness and contribution to sustainable building practices, particularly in regions where natural aggregates are scarce or expensive.

Environmental Considerations

From an environmental perspective, copper slag repurposes industrial waste, unlike traditional materials that deplete natural resources, aligning with global sustainability goals. However, the presence of heavy metals requires careful handling and disposal to prevent soil and water contamination. Regulatory compliance is crucial to mitigate these environmental risks, with some regions imposing stricter guidelines on the use and disposal of copper slag.

Usage Guidelines and Best Practices

When selecting materials for construction or abrasive blasting, it is essential to consider the specific requirements of the project. Copper slag is suitable for applications that benefit from its hardness, durability, and cost-effectiveness. However, its potential chemical reactivity and single-use nature in blasting operations may necessitate additional considerations. Best practices include conducting thorough compatibility tests, adhering to regulatory standards, and implementing effective dust control measures to ensure safe and sustainable use of copper slag.

By comparing copper slag with other materials, industry professionals can make informed decisions that balance performance, cost, and environmental impact.

Technical Reference for Copper Slag

Standards and Compliance Requirements

Copper slag must meet national and international standards to ensure safety and effectiveness. In the United States, the Occupational Safety and Health Administration (OSHA) limits free crystalline silica in abrasives to protect workers from silicosis. Copper slag, with less than 1% free crystalline silica, is more compliant with these regulations than traditional silica sand.

In the construction industry, copper slag used as an aggregate in concrete must meet standards related to particle size distribution, density, and chemical composition. European standards like EN 12620 provide guidelines for aggregates used in concrete. Copper slag may have different particle size distributions compared to natural aggregates like sand and gravel, which can affect its performance in concrete.

Technical Specifications and Properties

Hardness and Abrasive Potential

With a Mohs hardness of about seven, copper slag falls between quartz and topaz. When compared to other abrasives like coal slag, which has a lower hardness, copper slag is more effective at removing tough coatings, paint, and corrosion from surfaces during abrasive blasting. Its angular particle shape further enhances its cutting and scouring properties, making it a preferred choice for surface preparation.

Density and Specific Gravity

With a specific gravity of about 3.4 and a density of 115 to 120 pounds per cubic foot, copper slag is significantly denser than coal slag. This high density allows it to be reclaimed and reused multiple times during abrasive blasting operations, reducing waste and disposal costs. In contrast, lighter abrasives may be more easily carried away by air currents, leading to increased consumption and higher costs.

Chemical Composition

The primary components of copper slag are iron oxides and silicon oxides. This chemical composition differs from that of other construction materials. For example, compared to Portland cement, which is mainly composed of calcium silicates, the presence of iron oxides in copper slag can influence its reactivity when used in concrete. In some cases, the iron oxides may enhance the strength and durability of concrete, but in others, they may cause discoloration or affect the setting time.

Usage Guidelines and Best Practices

Abrasive Blasting

When using copper slag for abrasive blasting, it is important to consider the surface being treated. For softer metals or delicate surfaces, a lower pressure setting may be required to prevent damage. Compared to steel grit, which can be more aggressive, copper slag is generally more forgiving on surfaces while still providing effective cleaning. Additionally, proper dust control measures should be in place to minimize the risk of inhaling airborne particles.

Construction Applications

In concrete production, the replacement ratio of copper slag for sand should be carefully determined. Due to its low water absorption and higher slump, using too much copper slag can cause bleeding in concrete, leading to aesthetic and structural issues. Conducting trial mixes can help optimize copper slag’s performance in concrete. Compared to natural aggregates, copper slag may need extra additives or mix adjustments to achieve the desired workability and strength.

In road construction, copper slag’s anti – slip properties make it a valuable material. However, its angular shape may require special handling during compaction to ensure proper bonding with other road – building materials.

Regional Analysis of Copper Slag Usage

Usage Trends in Different Regions

Asia

Asia leads in copper slag production and usage, generating around 7.26 million tons each year. This significant output is driven by extensive copper mining and smelting operations. In countries like China and India, copper slag is widely used in construction, particularly in concrete and road construction, due to its high availability and cost-effectiveness. Additionally, its hardness and efficiency make it a popular choice for abrasive blasting in the region.

North America

In North America, copper slag is widely used in abrasive blasting and as an aggregate in concrete production, with the construction industry leveraging its durability and cost benefits. The region’s stringent environmental regulations and advanced waste management practices promote sustainable applications. The United States and Canada adhere to strict guidelines to mitigate potential environmental and health risks, ensuring safe use and disposal of copper slag.

Africa

Africa contributes around 1.23 million tons of copper slag annually. With increasing initiatives to recover metals from slag and reduce environmental impacts, African countries are exploring innovative uses for copper slag. In regions like Zambia and the Democratic Republic of Congo, where copper mining is significant, copper slag is used in construction and infrastructure projects. Efforts are being made to improve the recycling and reprocessing of copper slag to maximize resource recovery.

Europe and South America

Both Europe and South America utilize copper slag in construction and as an abrasive, though at lower volumes compared to Asia and North America. The European Union’s waste management and recycling directives promote the sustainable use of materials, including copper slag, in construction. South American countries, including Chile and Peru, are adopting copper slag in their construction industries, driven by the region’s robust mining activities.

Regional Regulations and Standards

Asia

Asian countries have varying regulations for copper slag usage. For instance, in India, the Bureau of Indian Standards (BIS) has established guidelines for using copper slag in concrete and road construction. These standards ensure that copper slag meets specific criteria for particle size distribution and chemical composition, promoting safe and effective use.

North America

In North America, the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) regulate the use of copper slag, particularly in abrasive blasting. These regulations focus on limiting exposure to harmful dust and ensuring proper disposal practices to prevent soil and water contamination.

Africa

African nations are developing regulations to manage the environmental and health impacts of copper slag. Countries with significant copper mining operations, such as Zambia, are implementing guidelines to promote the safe use and disposal of copper slag, encouraging its use in construction while minimizing potential risks.

Europe and South America

Europe has stringent environmental regulations that govern the use of industrial byproducts, including copper slag. The European Union’s directives emphasize the sustainable use of materials like copper slag in construction. South American countries are also aligning their regulations with international standards to ensure the safe and effective use of copper slag in various applications.

Case Studies from Various Parts of the World

Construction in India

In India, several construction projects have successfully utilized copper slag as a partial replacement for sand in concrete. These projects have demonstrated improvements in the compressive strength and durability of the concrete, showcasing copper slag’s potential to enhance construction quality while reducing costs.

Abrasive Blasting in the United States

In the United States, copper slag is effectively used for surface preparation in the shipbuilding and repair industry due to its efficiency in abrasive blasting. The material’s hardness and angular shape make it ideal for removing coatings and corrosion from metal surfaces, contributing to efficient and safer blasting processes.

Road Construction in Chile

Chile, a major copper producer, has implemented copper slag in road construction projects. The slag’s anti-slip properties and durability make it an excellent material for road surfaces, providing enhanced safety and longevity. These projects highlight the versatility and practical benefits of copper slag in infrastructure development.

Frequently Asked Questions

Below are answers to some frequently asked questions:

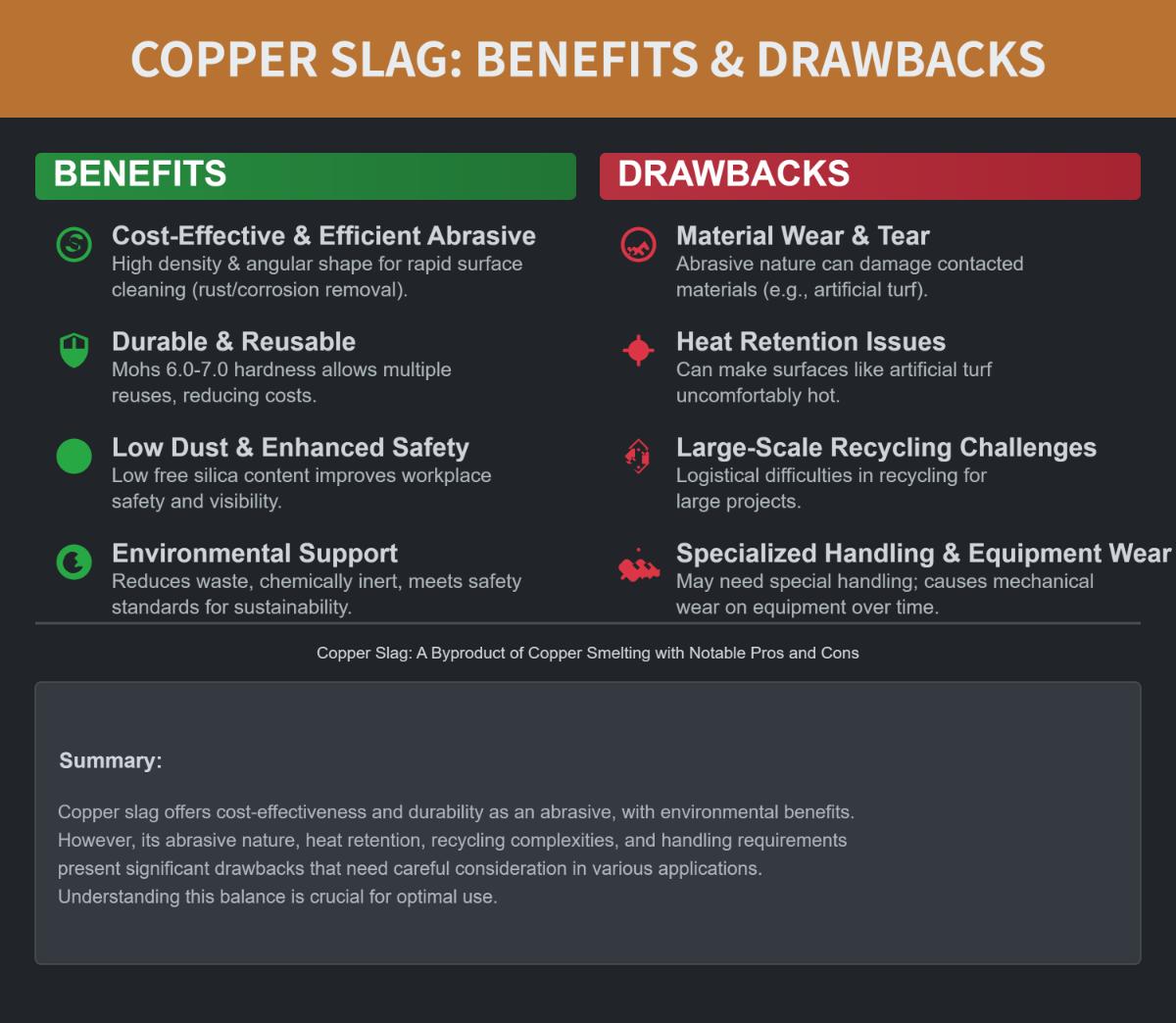

What are the benefits and drawbacks of using copper slag?

Copper slag, a byproduct of copper smelting, offers several notable benefits and drawbacks.

Benefits:

Copper slag is cost-effective and efficient, particularly as an abrasive material. Its high density and angular shape allow for effective surface preparation, reducing rust and corrosion quickly. Its durability, with a hardness of 6.0 to 7.0 on the Mohs scale, means it can be reused multiple times, minimizing replacement costs. Additionally, copper slag produces low dust due to its low free silica content, which enhances workplace safety and visibility. Environmentally, it supports sustainability by reducing waste and is chemically inert, meeting safety standards.

Drawbacks:

Despite its advantages, copper slag has some limitations. Its abrasive nature can cause wear and tear on materials it contacts, such as artificial turf. It also retains heat, which can make artificial turf uncomfortable in hot weather. Recycling copper slag in large-scale projects can be challenging due to logistical issues. Furthermore, it may require specialized handling due to its potential for causing mechanical wear on equipment over time.

How does copper slag compare to other materials in construction?

Copper slag, a by-product of copper smelting, has gained traction in the construction industry due to its advantageous properties. Compared to traditional construction materials like sand, gravel, and other abrasives, copper slag stands out for several reasons.

Firstly, copper slag enhances the durability and strength of concrete when used as a partial replacement for fine aggregates. Its high density and hardness contribute to improved compressive strength and reduced water absorption, making the concrete mix more workable and durable.

Economically, copper slag is often more cost-effective than traditional materials such as garnet and aluminum oxide, particularly in blasting applications, due to its reduced consumption rate and lower cost.

Environmentally, copper slag offers benefits as it contains less than 1% free crystalline silica, mitigating health risks and environmental impact. Additionally, its use in construction contributes to waste reduction and recycling efforts, aligning with environmental regulations.

However, potential drawbacks include the risk of heavy metal contamination if not properly managed and the possibility of bleeding in concrete when used in high ratios. Availability can also be limited in certain regions, impacting its widespread use.

Is copper slag environmentally friendly?

Copper slag, a byproduct of copper smelting, has both environmentally friendly aspects and risks. It can be used in blended cement production, reducing environmental impacts like abiotic depletion and global warming potential. In blasting, it’s an effective abrasive, reducing resource consumption and dust compared to traditional options. Metal recovery techniques can extract valuable metals, lessening environmental hazards. However, historical slag deposits may leach heavy metals, and it can contribute to acid mine drainage. If not managed properly, it poses health risks.

What are the common applications of copper slag in construction?

Copper slag, a by-product of copper smelting, is widely utilized in the construction industry due to its beneficial properties and environmental advantages. Its common applications include:

- Concrete Production: Copper slag is used as a partial replacement for fine aggregates like sand in concrete mixtures, enhancing workability, compressive strength, and reducing permeability.

- Road Construction: It serves effectively in road base and sub-base layers due to its high frictional properties and angular shape, which contribute to roadbed stability. It is also used in embankments and landfills for added stability.

- Abrasive and Surface Preparation: Due to its hardness and angular particles, copper slag is employed in blast cleaning and surface preparation of metal, concrete, and stone surfaces.

- Asphalt Mixtures and Insulation: It is added to asphalt mixtures to improve skid resistance and used in insulation applications due to its low thermal conductivity.

- Decorative and Landscaping Uses: The reddish-brown color of copper slag is aesthetically pleasing for pathways and decorative concrete finishes, and it is also used for erosion control.

- High-Density Applications: Copper slag is utilized in high-density concrete for nuclear shielding because of its density and hardness.

These applications highlight the versatility and practical benefits of copper slag in various construction contexts.

Are there any health risks associated with using copper slag?

Yes, there are health risks associated with using copper slag. Copper slag, a by-product of the smelting process, can pose several health hazards primarily due to its particulate matter and heavy metal content. During processes like abrasive blasting, copper slag generates dust that can be inhaled. Prolonged exposure to this dust may cause respiratory issues such as irritation, coughing, and even chronic conditions like chronic obstructive pulmonary disease (COPD). Additionally, copper slag can contain harmful metals like arsenic and lead, which can lead to severe health problems if exposure limits set by regulatory bodies like OSHA are exceeded. Direct contact with copper slag can also cause skin and eye irritation. To mitigate these risks, proper protective equipment, safe handling practices, and environmental controls are essential.

What are the technical specifications of copper slag?

Copper slag is a byproduct of the copper smelting process and has several technical specifications that make it suitable for various industrial applications. It has a high density, ranging from 100 to 120 lbs/cubic foot, which provides significant impact during blasting operations. The hardness of copper slag is between 6.0 and 7.5 on the Mohs scale, indicating its durability. The particles are angular, enhancing their cutting action for better surface preparation.

Chemically, copper slag is primarily composed of iron silicate with key components such as SiO(_2) (33-38%), FeO (51-58%), Al(_2)O(_3) (4-8%), and CaO (2-10%). Its low free silica content (less than 0.1%) makes it a safer alternative to other blasting media that contain higher levels of free silica, which can pose health risks such as silicosis.