Have you ever wondered about the hidden costs of the metals we rely on every day? Titanium, known for its strength and corrosion resistance, is a critical material in industries ranging from aerospace to medical devices. However, the environmental impact of titanium production is a topic that deserves closer scrutiny. This article delves into the complex processes involved in titanium mining and production, examining how these activities affect local ecosystems and contribute to pollution. We’ll explore the key environmental concerns, such as emissions and biodiversity loss, and discuss sustainable practices that can mitigate these impacts. By understanding the full environmental footprint of titanium, we can better appreciate the balance between its benefits and the need for more eco-friendly production methods. Ready to uncover the truths and solutions behind titanium production’s environmental impact? Read on to find out.

Titanium Production: An Overview

Titanium production involves extracting titanium metal from its ores and manufacturing it into titanium alloys. Titanium’s exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility make it crucial for industries such as aerospace, medical, and automotive.

Key Processes Involved in Titanium Production

Extraction and Purification

The extraction process begins with converting ores like ilmenite (FeTiO3) and rutile (TiO2) into titanium tetrachloride (TiCl4) through high-temperature chlorination, followed by purification using fractional distillation to remove impurities, ensuring a high-quality end product.

Sponge Production

Purified titanium tetrachloride is reduced with magnesium in an inert atmosphere to produce titanium sponge and magnesium chloride. This sponge, a porous form of titanium, is then crushed and pressed for further processing.

Alloy Creation and Forming

Titanium sponge is melted in a vacuum arc furnace with alloying elements like aluminum and vanadium, ensuring high purity and consistency in the resulting alloy. Another method, Cold Hearth Melting, uses an electron beam in a vacuum environment to remove inclusions and process waste chips, further refining the titanium.

Environmental Impact of Titanium Production

Titanium production has a significant environmental impact due to its energy-intensive processes. However, recycling byproducts like magnesium chloride helps reduce waste. Titanium’s high strength-to-weight ratio also contributes to less material usage in applications, improving fuel efficiency in sectors like aerospace.

Future Directions and Innovations

Alternative Processes

Research is ongoing to discover more efficient and cost-effective methods for titanium production. One promising approach is the FFC Cambridge process, which aims to reduce the environmental footprint and production costs associated with titanium manufacturing.

Increasing Demand

The versatile properties of titanium continue to drive its demand in various industries, including aerospace, automotive, and medical devices. As the demand grows, sustainable production methods become increasingly crucial to meet industry needs while minimizing environmental impact.

Understanding titanium production involves recognizing the complex processes and their implications on both industry and the environment. With continuous advancements and a focus on sustainability, the future of titanium production holds promise for more efficient and eco-friendly methods.

Titanium Mining and Its Environmental Effects

Overview of Titanium Mining Processes

Titanium mining extracts minerals containing titanium from various ore deposits. The primary ores used in titanium production are ilmenite (FeTiO3) and rutile (TiO2), which are typically found in beach sand deposits and hard rock deposits.

Surface Mining Techniques

Surface mining, also known as open-pit mining, is commonly used for extracting titanium ores. This technique involves removing the overburden, which is the soil and rock covering the mineral deposits. Heavy machinery, such as excavators and dump trucks, is used to transport the ore to processing facilities.

Dredging and Hydraulic Mining

In areas where titanium deposits are found in riverbeds or coastal regions, dredging and hydraulic mining are employed. Dredging uses large floating machines to collect sand and gravel rich in titanium minerals. Hydraulic mining uses high-pressure water jets to dislodge the ore from the riverbed or beach, which is then collected and processed.

Impact of Mining on Local Ecosystems

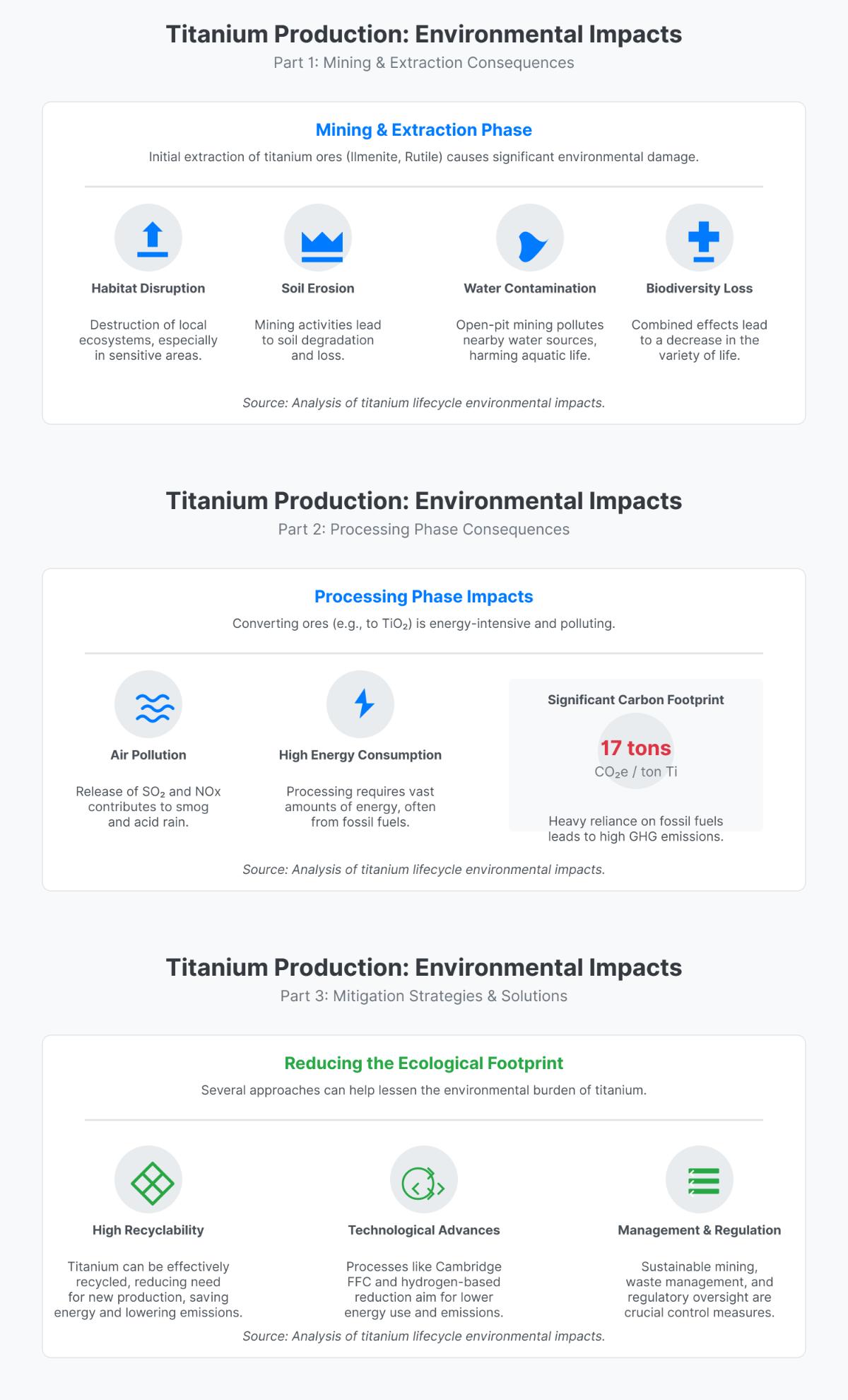

Habitat Disruption and Loss of Biodiversity

Titanium mining can have significant ecological impacts, particularly when it comes to habitat disruption. Removing vegetation and topsoil destroys local habitats, impacting both plant and animal life. In coastal regions, mining activities can disturb the nesting sites of marine turtles and other wildlife.

Soil Erosion and Water Contamination

Mining operations can cause soil erosion, leading to the loss of fertile topsoil and increased sedimentation in nearby water bodies. This sedimentation can negatively impact aquatic ecosystems, reducing water quality and harming fish and other aquatic organisms. Additionally, the use of chemicals in the extraction and processing of titanium can lead to water contamination if not properly managed.

Case Studies of Affected Regions

Okefenokee Swamp, Georgia

A proposed titanium mine near the Okefenokee Swamp in Georgia has raised environmental concerns. Experts warn that mining activities in this sensitive area could harm water quality, lower water levels, and increase the frequency and severity of droughts and wildfires. This swamp provides a vital habitat for many endangered species, and disturbances could lead to significant ecological consequences.

Kwale District, Kenya

In Kenya’s Kwale District, titanium mining has led to significant environmental and social impacts. The displacement of communities and the destruction of local ecosystems have been major concerns. Efforts are being made to mitigate these impacts through reforestation projects and community engagement, but challenges remain in balancing economic development with environmental preservation.

Sustainable Practices and Innovations

Recycling and Circular Economy

Recycling is a key sustainable practice in the titanium industry. Titanium has a high recyclability rate, approximately 95%, which reduces the need for new mining activities. By recycling titanium scrap, the industry can minimize its environmental footprint and conserve natural resources.

Advanced Extraction Technologies

Emerging technologies are being developed to reduce the environmental impact of titanium mining. These include hydrogen-based reduction and electrochemical processes that aim to lower CO2 emissions and energy consumption. These innovations are critical for making titanium production more sustainable and environmentally friendly.

Regulatory and Collaborative Efforts

Governments and industries are working together to implement stricter environmental standards and promote sustainable practices. Collaborative efforts include sharing best practices, investing in research and development, and enforcing regulations that protect ecosystems and reduce the carbon footprint of titanium production.

Key Challenges and Future Directions

Balancing Economic and Environmental Interests

The titanium industry faces the challenge of balancing economic growth with environmental stewardship. Ensuring that mining activities are conducted responsibly while promoting sustainable practices is essential for the long-term viability of the industry.

Enhancing Recycling and Waste Management

Improving recycling technologies and managing waste effectively can further reduce the environmental footprint of titanium production. Continued innovation in these areas will be crucial for minimizing the impact of titanium mining on the environment.

Titanium Dioxide (TiO₂): Uses and Environmental Concerns

Understanding Titanium Dioxide (TiO₂)

Titanium dioxide (TiO₂) is a versatile compound used in various industries due to its unique properties. Composed of one titanium atom and two oxygen atoms, TiO₂ is primarily found in two crystalline forms: rutile and anatase. These forms are refined for various industrial uses, leveraging their distinct characteristics.

Major Applications of Titanium Dioxide

Paints and Coatings

In the paints and coatings industry, titanium dioxide serves as a critical pigment. Its high refractive index and strong UV resistance provide excellent opacity, brightness, and whiteness to paints, while also protecting surfaces from UV degradation, enhancing the longevity of the coatings.

Cosmetics and Personal Care

TiO₂ is commonly used in sunscreens, foundations, and powders because it provides effective coverage and shields the skin from harmful ultraviolet rays. Its non-toxic nature makes it suitable for direct application on the skin.

Food and Pharmaceuticals

Titanium dioxide enhances the visual appeal of food products and helps in the uniform coating of pills, improving their stability and shelf life. The compound’s inertness ensures it does not react with other substances, maintaining the integrity of the products.

Plastics and Rubber

The addition of TiO₂ to plastics and rubber materials improves their UV resistance and color consistency. It helps prevent the degradation of these materials when exposed to sunlight, thereby extending their useful life and maintaining their aesthetic qualities.

Concrete

In the construction industry, titanium dioxide is incorporated into concrete to enhance its strength and UV resistance. It contributes to the durability and longevity of concrete structures, making them more resistant to environmental wear and tear.

Environmental Concerns Related to Titanium Dioxide

Production and Environmental Impact

Although TiO₂ is non-toxic and inert in bulk form, the production processes can be energy-intensive and result in emissions, contributing to environmental degradation. High energy consumption and potential emissions from these processes warrant attention.

Nanoparticles and Safety Concerns

The use of nano-sized titanium dioxide particles has grown, particularly in applications like sunscreens and photocatalytic materials. However, these nanoparticles pose significant health and environmental concerns. Studies indicate that inhalation of TiO₂ nanoparticles can induce oxidative stress and has been classified as possibly carcinogenic. Their environmental impact is also under scrutiny, as nanoparticles can accumulate in ecosystems, potentially disrupting ecological balance.

Photocatalytic Applications

Titanium dioxide’s photocatalytic properties are harnessed for environmental remediation. It is used to break down pollutants and organic matter in water and air, offering a solution for pollution control. However, the management of these applications requires careful oversight to avoid unintended consequences, such as the formation of harmful byproducts during the photocatalytic process.

Recent Developments and Future Outlook

Recent advancements in titanium dioxide research focus on improving its photocatalytic efficiency and expanding its applications. Modifications to the surface structure of TiO₂ or doping it with other elements aim to enhance its performance in pollution mitigation and energy production. Further studies are essential to fully understand and mitigate the potential environmental impacts associated with the production and use of titanium dioxide.

Environmental Impact of Titanium Production

Mining and Extraction

The environmental impact of titanium production starts with the mining and extraction processes. Titanium ores, such as ilmenite and rutile, are typically mined using surface mining techniques like open-pit mining, which can cause significant environmental disruption by removing large amounts of soil and rock to access the ore. This method leads to deforestation, habitat destruction, and loss of biodiversity. The removal of vegetation and topsoil can also result in soil erosion and sedimentation in nearby water bodies, negatively affecting aquatic ecosystems.

Dredging and hydraulic mining methods, used especially in coastal and riverbed deposits, cause similar environmental issues, including habitat destruction and water pollution from sediment disturbance.

Processing and Refining

The environmental impact extends to the processing and refining stages. The chlorination and sulfate processes used to refine titanium ores generate several chemical byproducts that can be harmful if not managed properly. These processes require significant energy input, contributing to greenhouse gas emissions. Emissions of sulfur dioxide and nitrogen oxides from titanium dioxide (TiO₂) production can lead to air pollution and acid rain, further harming the environment.

Waste Management

Waste management is another critical aspect of the environmental impact of titanium production. Mining and processing activities generate tailings and other waste materials that contain heavy metals and toxic substances. If these wastes are not treated and disposed of properly, they can contaminate soil and water resources, posing risks to both ecosystems and human health. Effective waste management practices are essential to mitigate these risks and minimize the environmental footprint of titanium production.

Carbon Footprint

Producing one ton of titanium can generate up to 17 tons of CO₂ emissions, highlighting the need for sustainable practices to reduce energy use and emissions. Advanced technologies, such as the Cambridge FFC Process, are being developed to address these concerns by offering less energy-intensive methods for titanium production.

Recycling and Sustainability

Recycling plays a crucial role in reducing the environmental impact of titanium production. Titanium is highly recyclable, and recycling titanium scrap significantly lowers energy consumption and emissions compared to primary production. By promoting recycling and adopting sustainable practices, the titanium industry can reduce the need for new mining and processing activities, thus minimizing its environmental footprint.

Comparison to Other Metals

When compared to other metals, titanium production generally has a lower ecological footprint. Metals like gold and silver often involve more intensive labor practices and the use of toxic chemicals, leading to higher environmental impacts. While titanium production does pose environmental challenges, it is considered a more sustainable option due to its recyclability and the ongoing development of greener technologies.

Sustainable Practices in Titanium Production

Introduction to Sustainable Practices

Adopting sustainable practices in titanium production is crucial for reducing the industry’s environmental impact. With the increasing demand for titanium in various sectors, including aerospace, medical, and automotive, it is essential to implement methods that minimize energy consumption, emissions, and waste generation.

Innovative Production Methods

The Velta Ti Process and hydrogen-based reduction are transforming the titanium industry by offering more energy-efficient and environmentally friendly alternatives to traditional methods. The Velta Ti Process eliminates the need for chlorine and reduces solid waste to zero, significantly lowering CO2 emissions. Hydrogen-based reduction uses hydrogen instead of carbon to reduce titanium ores, resulting in lower CO2 emissions and energy consumption. By adopting these innovative methods, manufacturers can contribute to global efforts to implement cleaner industrial practices.

Recycling and Reuse

Titanium’s recyclability is a key factor in sustainability. With a recycling rate of about 95%, titanium can be reused multiple times without losing its structural properties. Recycling titanium scrap reduces the demand for new mining and the associated environmental impacts. Promoting recycling helps conserve resources and minimizes the ecological footprint of the industry.

Advanced Manufacturing Technologies

3D printing, a form of additive manufacturing, provides significant advantages for sustainable titanium production. This technique allows for minimal waste production and reduced material requirements, as it builds components layer by layer. Not only does 3D printing enhance sustainability, but it also enables the creation of complex designs that are difficult to achieve with traditional methods.

Nanotwinned titanium, developed through cryo-forging, enhances the metal’s strength and ductility while offering potential for cost-effective, scalable production. This innovative method could lead to more sustainable manufacturing processes by reducing energy consumption and waste generation.

Sustainable Mining Practices

Responsible sourcing from mines that adopt sustainable practices is crucial for minimizing environmental damage. Sustainable mining practices include minimizing habitat destruction and protecting biodiversity. Additionally, ensuring worker safety is paramount. By implementing these practices, the titanium industry can reduce its impact on local ecosystems and promote long-term environmental stewardship.

Renewable Energy Integration

Harnessing renewable energy sources such as solar and wind can greatly lower the carbon footprint of titanium production. Integrating renewable energy into manufacturing processes helps decrease reliance on fossil fuels and lowers greenhouse gas emissions. Companies that embrace renewable energy can improve their sustainability credentials and contribute to global environmental goals.

Future Directions

To fully realize the potential of sustainable titanium production, ongoing investment in research and development is essential. Collaborative efforts among industries and governments will play a critical role in advancing sustainable technologies and practices. Implementing stricter environmental regulations and promoting transparency in production processes will further support the industry’s move towards sustainability.

By adopting innovative production methods, enhancing recycling and reuse, utilizing advanced manufacturing technologies, and integrating renewable energy, the titanium industry can significantly reduce its environmental impact and pave the way for a more sustainable future.

Comparative Analysis: Titanium vs Other Metals

Titanium is highly valued for its excellent strength-to-weight ratio and corrosion resistance, making it ideal for high-performance applications. When comparing titanium to other metals such as gold, silver, stainless steel, and tungsten, it is essential to consider the environmental impact of their production processes. This analysis highlights the environmental benefits and challenges associated with titanium production compared to these other metals.

Environmental Impact of Titanium Production

Mining and Extraction

The mining processes for titanium’s primary minerals, ilmenite and rutile, include surface mining, dredging, and hydraulic mining, which can cause habitat destruction, soil erosion, and water pollution. However, titanium mining tends to be less labor-intensive and uses fewer toxic chemicals compared to the extraction processes for some other metals.

Emissions and Pollution

The production of titanium dioxide releases sulfur dioxide and nitrogen oxides, which contribute to air pollution and acid rain. Nonetheless, the industry has been making strides in reducing these emissions through the implementation of cleaner technologies and more efficient production processes.

Comparative Environmental Impact

Gold and Silver

Gold and silver mining are infamous for their severe environmental and social impacts, often involving hazardous substances like cyanide and mercury, which pose significant risks to both the environment and human health. Additionally, gold and silver mining practices frequently involve significant labor and human rights issues, exacerbating their negative impact.

Stainless Steel

Stainless steel production is energy-intensive, primarily due to the high temperatures required for smelting and alloying. Although stainless steel is highly recyclable, its production process does not match the relatively lower ecological footprint of titanium. The energy demands and associated emissions of stainless steel production are generally higher than those for titanium.

Tungsten

Tungsten mining shares many of the environmental challenges seen in gold and silver extraction. The mining process often leads to habitat destruction and significant energy consumption. Additionally, the social impacts of tungsten mining can be severe, similar to those associated with precious metals.

Benefits and Drawbacks of Using Titanium

Advantages

- Recyclability: Titanium is highly recyclable, with minimal quality loss, making it a sustainable choice for various applications.

- Lower Toxic Chemical Usage: Compared to metals like gold and silver, titanium production involves fewer toxic chemicals, reducing the risk of environmental contamination.

- High Strength-to-Weight Ratio: Titanium’s superior strength-to-weight ratio means that less material is required for structural applications, leading to potential reductions in

Challenges

Titanium mining can disrupt local ecosystems and result in habitat destruction, similar to other mining activities. The production of titanium dioxide results in emissions that contribute to air pollution, although these emissions are typically lower than those from the production of other metals.

Sustainable Practices in Titanium Production

Recycling and Reuse

Titanium’s recyclability is a significant advantage in reducing the environmental impact of its production. By recycling titanium scrap, the industry can decrease the need for new mining and lower carbon emissions.

Innovative Technologies

Emerging technologies, such as the Cambridge FFC Process and hydrogen-based reduction, aim to reduce the energy consumption and emissions associated with titanium production. These innovations are crucial for making titanium production more sustainable and environmentally friendly.

Sustainable Mining Techniques

Implementing sustainable mining practices, such as minimizing land disturbance and rehabilitating ecosystems post-mining, can help mitigate the environmental impact of titanium extraction. These practices are increasingly being adopted to promote long-term environmental stewardship.

Comparative Analysis with Other Eco-Friendly Materials

Introduction to Eco-Friendly Materials

In the quest for sustainability, various materials are compared for their environmental impact, including titanium, which is known for its strength, durability, and recyclability. This section explores how titanium stacks up against other eco-friendly materials, highlighting their advantages and disadvantages from an environmental perspective.

Bamboo

Bamboo is one of the most environmentally friendly materials available. It grows rapidly, reaching maturity in just a few years, and does not require replanting after harvesting due to its extensive root system. This makes bamboo a highly renewable resource.

Environmental Benefits

- Carbon Sequestration: Bamboo absorbs more carbon dioxide and releases more oxygen than many other plants, making it beneficial for reducing greenhouse gases.

- Minimal Agricultural Impact: Requires less water and no pesticides or fertilizers, reducing its environmental footprint compared to traditional crops.

- Soil Health: The root system helps prevent soil erosion and maintain soil health.

Comparison with Titanium

Titanium’s exceptional strength and durability make it ideal for heavy-duty industrial applications, whereas bamboo is not suitable for such uses. However, bamboo’s low environmental impact in terms of cultivation and processing makes it an excellent choice for products where such properties are sufficient.

Recycled Plastics

Recycled plastics are gaining popularity as a sustainable material option. By reprocessing used plastics, the demand for new plastic production is reduced, conserving resources and reducing pollution.

Environmental Benefits

- Waste Reduction: Recycles plastic waste that would otherwise end up in landfills or oceans, reducing environmental pollution.

- Energy Conservation: Producing recycled plastics typically consumes less energy than producing new plastics from raw materials.

- Resource Efficiency: Reduces the need for petroleum, a non-renewable resource, used in plastic production.

Comparison with Titanium

Recycled plastics offer significant environmental benefits, especially in waste reduction and energy conservation, but they lack the strength, durability, and resistance to extreme conditions that titanium provides. Titanium’s high recyclability also means that its environmental impact can be mitigated through effective recycling programs, making it a strong competitor in terms of sustainability.

Wood

Wood is a traditional material that, when sourced sustainably, can be environmentally friendly. Responsible forestry practices ensure that wood remains a renewable resource.

Environmental Benefits

- Carbon Storage: Wood acts as a carbon sink, storing carbon dioxide absorbed during the tree’s growth.

- Renewability: When forests are managed sustainably, wood can be a continually renewable resource.

- Biodegradability: Wood products are biodegradable, reducing long-term waste.

Comparison with Titanium

Sustainably sourced wood has a lower environmental impact during production compared to titanium. However, wood is not as strong, durable, or resistant to corrosion as titanium, limiting its use in industrial applications. Titanium’s recyclability and longevity offer advantages in applications where wood’s properties fall short.

Hemp

Hemp is another renewable resource that is gaining attention for its environmental benefits. It grows quickly and can be used in a wide range of products, from textiles to construction materials.

Environmental Benefits

- Low Input Requirements: Requires minimal water, pesticides, and fertilizers, making it less environmentally taxing than many other crops.

- Soil Health: Improves soil structure and can be used in crop rotation to enhance soil fertility.

- Carbon Absorption: Absorbs significant amounts of carbon dioxide, helping to mitigate climate change.

Comparison with Titanium

Hemp grows quickly and has a low environmental impact, making it a highly sustainable material. Although hemp is suitable for many uses, titanium’s superior strength and resistance to harsh environments are essential for industries like aerospace and medical devices.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the environmental impacts of titanium production?

Titanium production has several environmental impacts throughout its lifecycle, from mining and extraction to processing and disposal. The initial mining of titanium ores, such as ilmenite and rutile, often leads to significant habitat disruption and soil erosion. This can result in deforestation and the destruction of local ecosystems, particularly in sensitive areas. Moreover, open-pit mining methods used in titanium extraction can contaminate nearby water sources, leading to pollution and biodiversity loss.

During the processing phase, producing titanium dioxide (TiO₂), a common byproduct, releases pollutants like sulfur dioxide and nitrogen oxides into the atmosphere. These emissions contribute to air pollution and acid rain, negatively affecting air quality and local ecosystems. Additionally, titanium production is energy-intensive, with a high carbon footprint due to the reliance on fossil fuels. For instance, generating one ton of titanium can produce up to 17 tons of CO₂ equivalent emissions.

However, titanium is highly recyclable, which helps mitigate some of these environmental impacts. Recycling titanium reduces the need for new material extraction and processing, thereby lowering energy consumption and emissions. Advances in technology, such as the Cambridge FFC Process and hydrogen-based reduction, are also helping to reduce carbon emissions by making production more energy-efficient.

Implementing sustainable mining practices, effective waste management, and regulatory oversight are crucial strategies to minimize the ecological footprint of titanium production. These measures can help protect ecosystems, manage pollutants, and ensure responsible resource use.

How does titanium mining affect ecosystems?

Titanium mining significantly affects ecosystems through habitat destruction, soil erosion, water pollution, and air pollution. The open-pit mining methods often used for titanium extraction lead to deforestation and the destruction of habitats, which disrupts local ecosystems and results in biodiversity loss. Additionally, the extraction process can contaminate nearby water sources with heavy metals and other pollutants, posing risks to aquatic life and human health. This has been observed in regions like the Okefenokee Swamp in Georgia, where mining activities threaten to lower water levels and increase pollution. Air pollution is another concern, as titanium production releases harmful pollutants such as sulfur dioxide and nitrogen oxides, contributing to air quality degradation and acid rain. The harmful effects of airborne pollutants can extend far beyond the immediate vicinity of the mining site, affecting broader regions and contributing to global environmental issues.

What sustainable practices can reduce the environmental impact of titanium production?

Sustainable practices that can reduce the environmental impact of titanium production include recycling and reuse, innovative production technologies, energy efficiency, and sustainable mining practices. Recycling titanium is highly effective, as it can be done multiple times without significant quality loss, reducing the need for new mining and extraction. Innovative technologies, such as the Velta Ti Process, lower energy consumption and CO2 emissions, making production more efficient and eco-friendly. Using renewable energy sources like solar and wind power can significantly reduce the carbon footprint of titanium production. Additionally, sustainable mining practices, which minimize environmental damage and protect biodiversity, are crucial. Proper waste management through recycling and byproduct treatment further contributes to reducing the environmental impact. Collaborative efforts between industries, research institutions, and governments can drive innovation and support sustainable practices in titanium production.

How is titanium dioxide (TiO₂) used in industry, and what are the environmental concerns?

Titanium dioxide (TiO₂) is widely used in various industries due to its desirable properties such as high refractive index and strong UV resistance. It is primarily utilized in paints and coatings to enhance whiteness and opacity, making colors more vibrant and durable. In plastics and rubber, TiO₂ improves heat and light resistance, protecting these materials from ultraviolet rays. Additionally, TiO₂ is a key ingredient in cosmetics and sunscreens for its ability to absorb and reflect harmful UV radiation, providing sun protection without leaving a white cast on the skin.

However, the production and use of TiO₂ pose several environmental concerns. The manufacturing processes, including the chloride and sulfate methods, are energy-intensive and can generate hazardous byproducts like chlorine and sulfuric acid. Waste management and disposal are critical to prevent environmental contamination. TiO₂’s presence in products like paints and sunscreens can lead to chemical runoff, indirectly affecting ecosystems. Furthermore, regulatory bodies have raised health concerns about TiO₂ in food products, leading to restrictions in certain regions. These issues underscore the need for sustainable practices and ongoing assessment of TiO₂’s environmental impact.

Are there any green technologies specific to titanium production?

Yes, there are several green technologies specific to titanium production that aim to reduce its environmental impact. One notable innovation is the Velta Ti Process, which significantly lowers energy consumption and emissions compared to the traditional Kroll process. This method eliminates the need for chlorine, produces no liquid waste, and transforms solid waste into sellable byproducts, resulting in more than five times lower carbon emissions.

Additionally, electrochemical reduction and selective mineral separation are being explored to make titanium extraction more efficient and environmentally friendly, focusing on reducing energy use and emissions. Companies are also adopting sustainable mining practices, such as land reclamation and improved water management techniques, to mitigate the ecological footprint of titanium extraction.

Recycling plays a crucial role in green technologies for titanium production. Titanium’s high recyclability reduces the need for raw material extraction and lowers the carbon footprint. Technologies like Green TitaniumTM focus on remelting and reusing titanium scrap and waste, significantly reducing CO2 emissions.

Lastly, some titanium production facilities are integrating renewable energy sources, such as solar microgrids, to power their operations, further reducing reliance on non-renewable energy. These advancements highlight the industry’s commitment to sustainability.

What are the economic benefits of sustainable titanium production?

Sustainable titanium production offers numerous economic benefits, primarily due to its high recyclability, reduced energy consumption, and long-term cost savings. Titanium’s recycling rate is approximately 95%, which significantly lowers energy requirements compared to producing it from raw ore. This reduction in energy consumption also helps decrease greenhouse gas emissions. Although the initial costs of titanium extraction and processing are high, its durability and resistance to corrosion lead to substantial savings over time, especially in industries like aerospace and offshore wind turbines. Additionally, recycling titanium ensures a stable supply chain and reduces dependence on raw material imports, conserving natural resources and diminishing the ecological impacts of mining. Innovations in production technologies, such as electrochemical processes and hydrogen-based reduction, further enhance cost-efficiency and environmental sustainability. Overall, these factors make sustainable titanium production economically advantageous, supporting both industry growth and environmental goals.