Carbon Steel and Alloy Steel

Carbon Steel

(1) Classification of Carbon Steel

1) Carbon steel can be categorized into two main types based on its application: carbon structural steel and carbon tool steel.

Carbon structural steel is used to manufacture various engineering structures and machine parts. The carbon steel used for engineering structures is typically low-carbon steel, which has excellent weldability and is generally not heat-treated, being used in its hot-rolled state.

Carbon steel for machine parts usually contains less than 0.6% carbon by weight and has good mechanical properties, requiring heat treatment before use.

Carbon tool steel is used to make various cutting tools, measuring tools, and molds. It has a higher carbon content and, after appropriate heat treatment, exhibits high strength, hardness, and wear resistance.

2) Based on carbon content, carbon steel can be divided into three categories:

- Low-carbon steel: C<0.25%;

- Medium-carbon steel: C=0.25% to 0.60%;

- High-carbon steel: C>0.60%.

3) According to the different quality percentages of sulfur (S) and phosphorus (P), carbon steel can be classified into four grades:

- Ordinary steel: S≤0.050%, P≤0.045%;

- Quality steel: S≤0.035%, P≤0.035%;

- High-grade quality steel: S≤0.020%, P≤0.030%;

- Premium quality steel: S≤0.015%, P≤0.025%.

4) Classification by smelting method.

According to the type of furnace used for smelting, carbon steel can be divided into open-hearth steel, converter steel, and electric furnace steel. Based on the deoxidation process during smelting, carbon steel can also be categorized into killed steel, semi-killed steel, rimmed steel, and special killed steel.

Carbon Steel Grades, Properties, and Applications

1) General Carbon Structural Steel. Also known as carbon structural steel, its grade is composed of the letter representing the yield strength (Q), the numerical value of the yield strength, quality grade symbols, and deoxidation method symbols, in that order, such as Q235AF. Examples of the grades, chemical compositions, mechanical properties, and applications of general carbon structural steel can be found in Table 1-5.

2) Quality Carbon Structural Steel. The grade of quality carbon structural steel is indicated by two digits, which represent the average carbon content in the steel as a percentage by ten thousandths.

For example, steel 45 indicates a quality carbon structural steel with an average carbon content of 0.45%. Examples of the grades, chemical compositions, mechanical properties, and applications of quality carbon structural steel can be found in Table 1-6.

Table 1-5: Grades, Chemical Composition, Mechanical Properties, and Examples of Applications for General Carbon Structural Steel

| Grade | Level | Chemical composition (%) not greater than | Deoxidation Method | Mechanical properties | Example of use | ||||||

| Wc | WMn | Wsi | Ws | Wp | σs/MPa | σb/MPa | δ5 (%) | ||||

| Q195 | —— | 0.12 | 0.5 | 0.3 | 0.040 | 0.035 | F, Z | 195 | 315~430 | 33 | Structural components that bear small loads (such as rivets, washers, anchor bolts, cotter pins, tie rods, threaded rebars, etc.), stampings and welded parts |

| Q215 | A | 0.15 | 1.2 | 0.35 | 0.050 | 0.045 | F, Z | 215 | 335~450 | 31 | |

| B | 0.045 | ||||||||||

| Q235 | A | 0.22 | 1.4 | 0.35 | 0.050 | 0.045 | F, Z | 235 | 370~500 | 26 | Thin plates, profiles, bolts, nuts, rivets, tie rods, gears, shafts, connecting rods, etc., Q235C, Q235D can be used as important welded structural components |

| B | 0.20 | 0.045 | |||||||||

| C | 0.17 | 0.040 | 0.040 | Z | |||||||

| D | 0.035 | 0.035 | TZ | ||||||||

| Q275 | A | 0.24 | 1.5 | 0.35 | 0.050 | 0.045 | F, Z | 275 | 410~540 | 22 | Parts bearing medium loads, such as keys, chains, tie rods, rotating shafts, sprockets, bolts and threaded rebars, etc. |

| B | 0.21 | 0.045 | Z | ||||||||

| C | 0.2 | 0.040 | 0.040 | Z | |||||||

| D | 0.035 | 0.035 | TZ | ||||||||

Note:

1. Symbols in the table: A, B, C, D represent quality grades; F represents boiling steel; Z represents killed steel; TZ represents special killed steel.

2. δ₅ indicates that the gauge length of the tensile specimen is five times its diameter, i.e., L 0 =5d0 .

Table 1-6: Grades, Chemical Composition, Mechanical Properties, and Application Examples of High-Quality Carbon Structural Steel

| Grade | Chemical composition (%) | Mechanical properties (not less than) | Example of use | |||||||

| Wc | WSi | WMn | σb/MPa | σs/MPa | δ(%) | ψ(%) | HBW (Hot rolled) | dK (J/m²) | ||

| 08 10 | 0.05~0.11 0.07~0.13 | 0.17~0.37 0.17~0.37 | 0.35~0.65 0.35~0.65 | 325 335 | 195 205 | 33 31 | 60 55 | 131 137 | Various shapes of stampings, tie rods, gaskets, etc. | |

| 20 | 0.17~0.23 | 0.17~0.37 | 0.35~0.65 | 410 | 245 | 25 | 55 | 156 | Tie rods, lifting rings, hooks, etc. | |

| 35 | 0.32~0.39 | 0.17~0.37 | 0.50~0.80 | 530 | 315 | 20 | 45 | 197 | Shafts, bolts, nuts, etc. | |

| 40 45 | 0.39~0.44 0.42~0.50 | 0.17~0.37 0.17~0.37 | 0.50~0.80 0.50~0.80 | 570 600 | 335 355 | 19 16 | 45 40 | 217 229 | 6×105 5×105 | Gears, crankshafts, connecting rods, couplings, shafts, etc. |

| 60 65 | 0.57~0.65 0.62~0.70 | 0.17~0.37 0.17~0.37 | 0.50~0.80 0.50~0.80 | 675 710 | 400 420 | 12 10 | 35 30 | 255 255 | Springs, spring washers, etc. | |

3) Carbon Tool Steels.

The grades of carbon tool steels are denoted by the letter T followed by a number. The letter T stands for carbon tool steel, while the number indicates the average carbon content in the steel, expressed as a thousandth.

For instance, T10 represents a carbon tool steel with an average carbon content of 1.0%. High-grade premium carbon tool steels are designated with an “A” after the grade number, such as T10A. For details on the grades, chemical composition, mechanical properties, and applications of carbon tool steels, see Table 1-7.

Table 1-7: Grades, Chemical Composition, Mechanical Properties, and Applications of Carbon Tool Steels

| Grade | Chemical Composition (%) | Heat Treatment Heating Temperature/°C | Hardness HRC | Example Uses | |||||

| Wc | WSi | WMn | WS | WP | Quenching | Tempering | |||

| T7 | 0.65~0.74 | ≤0.40 | 800~820 (Water Quench) | 180~200 | 60~62 | Hammerheads, saws, drill bits, chisels, etc. | |||

| T8 | 0.75~0.84 | ≤0.40 | 780~800 (Water Quench) | 180~200 | 60~62 | Punches, woodworking tools, etc. | |||

| T10 T10A | 0.95~1.04 | ≤0.35 | ≤0.40 | <0.03 | <0.035 | 760~780 (Water Quench) | 180~200 | 60~62 | Taps, dies, saw blades, planer blades, small punches, etc. |

| T13 T13A | 1.25~1.35 | ≤0.40 | 760~780 (Water quenched) | 180~200 | 60~62 | Files, measuring tools, scrapers, etc. | |||

Alloy Steel

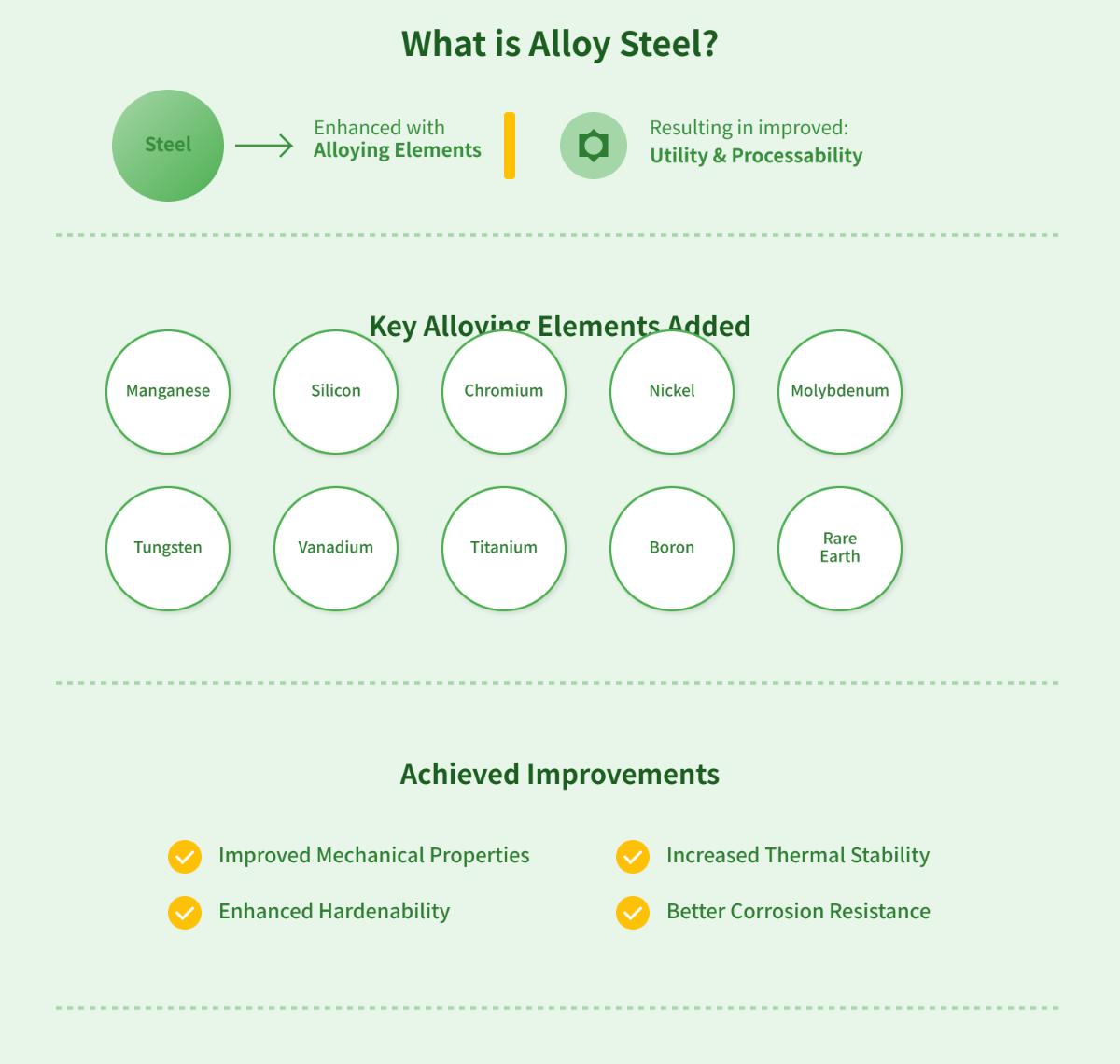

Alloy steel, an advanced form of carbon steel, is enhanced by the addition of certain alloying elements, thereby improving its utility and processability.

Commonly added alloying elements include manganese, silicon, chromium, nickel, molybdenum, tungsten, vanadium, titanium, boron, and rare earth elements. These elements can improve the steel’s overall mechanical properties, hardenability, thermal stability, and corrosion resistance.

(1) The role of alloying elements in steel

1) Solid solution strengthening: Most alloying elements can dissolve in ferrite to varying degrees, thereby increasing the strength and hardness of steel while reducing its plasticity and toughness.

Some alloying elements, such as Mn, Cr, and Ni, when properly proportioned, can not only strengthen the ferrite but also enhance the toughness of the steel, thereby providing it with excellent overall mechanical properties.

2) Secondary phase strengthening: When the affinity of the alloying element with carbon is greater than that of iron with carbon, it can not only dissolve in ferrite but also form alloy carbides and carbides. These components all have high strength and stability, thereby enhancing the strength, hardness, and wear resistance of steel.

3) Grain refinement strengthening: Elements like V, Ti, Nb, Zr that form strong carbides and Al, which forms strong nitrides, can create stable carbide and nitride particles. These particles inhibit the growth of austenite grains and refine ferrite grains. Fine-grained steel has superior mechanical properties, especially in significantly enhancing the toughness of the steel.

4) Increasing the hardenability of steel: Except for Co, all alloying elements that dissolve in austenite can increase the stability of supercooled austenite, shifting the isothermal transformation curve to the right and reducing the critical cooling speed of the steel.

Therefore, a greater hardened layer depth can be achieved when cooled in the same quenching medium, or when the same hardened layer depth is desired, a quenching medium with lower cooling capacity can be used to reduce quenching stress in the workpiece, minimizing deformation and cracking.

5) Improving the temper resistance of steel: Alloying elements significantly impact the tempering process of steel.

Generally, alloying elements make martensite less prone to decomposition during tempering, hinder carbide growth, and increase the temperature at which these transformations occur. This slows the reduction in steel hardness as the tempering temperature increases, thereby enhancing its temper resistance.

6) Giving steel certain special properties: When a certain amount of specific alloying elements are added to steel, the structure and properties of the steel undergo unique changes, resulting in alloy steel with special properties, such as stainless steel, heat-resistant steel, and wear-resistant steel.

(2) Types of Alloy Steel

Alloy steel can be categorized as: structural alloy steel, tool alloy steel, and special performance steel, based on its usage. Depending on the content of alloy elements, alloy steel can be classified into low alloy steel (wM<5%), medium alloy steel (wM=5%~10%), and high alloy steel (wM>10%).

(3) Designations, Mechanical Properties, and Applications of Structural Alloy Steel

Structural alloy steel includes steel for engineering structures and machinery manufacturing. The designations of structural alloy steel are generally composed of the average carbon mass fraction (expressed in ten-thousandths) + symbol of the alloy element + mass fraction of the alloy element (expressed in percentages), though there are exceptions.

Examples of commonly used structural alloy steel designations, their mechanical properties, and applications can be seen in Table 1-8.

Table 1-8: Examples of Designations, Mechanical Properties, and Applications of Commonly Used Structural Alloy Steel

| Steel Category | Grade | Heat Treatment Temperature/°C | Mechanical Properties | Example of Use | |||

| Quenching | Tempering | σb/MPa | σs/MPa | δ5(%) | |||

| Low Alloy High-Strength Structural Steel | Q345 Q390 | — | — | 510~660 530~680 | 345 390 | 22 20 | Bridges, Ships, Pressure Vessels, etc. |

| Alloy Carburizing Steel | 20Cr 20CrMnTi | 880 (Water, Oil) 860 (Oil) | 200 200 | 834 1079 | 539 834 | 10 10 | Gears, Piston Pins, Automobile (Tractor) Transmission Gears, etc. |

| Alloy Quenched and Tempered Steel | 40Cr 35CrMo | 850 (Oil) 850 (Oil) | 500 550 | 1000 1000 | 800 850 | 9 12 | Machine Tool Spindles, Crankshafts, Connecting Rods, Gears, etc. |

| Alloy Spring Steel | 60Si2Mn 50CrVA | 850 (Oil) 850 (Oil) | 480 500 | 981 1274 | 785 1127 | 5(δ10) 10(δ10) | Leaf Springs, Coil Springs, etc. on Automobiles (Tractors) |

1) Low-Alloy High-Strength Structural Steel. This type of steel is derived from low-carbon steel with the addition of a small amount of alloy elements (wM <5%). Generally used in engineering structures, it maintains relatively low strength, but possesses excellent plasticity, toughness, and weldability. Affordable and typically used in a hot-rolled condition, it undergoes normalizing treatment when necessary to enhance its strength.

Low-alloy high-strength structural steel is primarily used in the manufacturing of bridges, ships, boilers, high-pressure vessels, oil pipelines, and large steel structures.

2) Alloy Carburized Steel. Alloy carburized steel refers to alloy steel used after carburizing treatment. This type of steel has a lower mass fraction of carbon (0.15%~0.25%) to ensure that the core of the workpiece has high strength and toughness, while the surface, after carburizing and low-temperature tempering, exhibits high hardness (58~64HRC) and abrasion resistance.

Alloy carburized steel is mainly used in the manufacturing of parts requiring high wear resistance and dynamic load-bearing, such as gears in car and tractor transmissions, camshafts in internal combustion engines, etc. Commonly used alloy carburized steels include 15Cr, 20Cr, 20CrMnTi, and others.

3) Alloy Tempered Steel. This type of steel generally has a carbon content of 0.25%~0.45%. After quenching and high-temperature tempering (tempering), it develops a tempered sorbite structure, providing the steel with a good combination of high strength and toughness.

It is primarily used for manufacturing parts that withstand significant alternating loads and various complex stresses, such as connecting rods, transmission shafts, machine tool spindles, gears, cams, etc., on cars and tractors. Commonly used alloy tempered steels include 40Cr, 35CrMo, 40CrNiMo, and others.

4) Alloy Spring Steel. Alloy spring steel refers to the type of alloy steel used in the manufacture of various springs and elastic components. This type of steel generally has a carbon mass fraction of 0.50%-0.65% and contains alloy elements such as Mn, Si, Cr, and V.

After quenching and medium-temperature tempering, it develops a tempered troostite structure, exhibiting a high elastic limit and yield strength. Commonly used alloy spring steels include 65Mn and 50CrV, among others.

(4) Grades, Mechanical Properties, and Applications of Alloy Tool Steel

Alloy tool steel, which includes cutting tool steel, die steel, and measuring tool steel, is formed by adding alloying elements to carbon tool steel. The grades of alloy tool steel are generally composed of the average mass fraction of carbon in the steel (expressed in permillage) + the symbol of the alloy element + the content of the alloy element.

If the mass fraction of carbon exceeds 1.0%, it is not indicated in the grade. Please refer to Table 1-9 for examples of the grades, heat treatment status, and applications of commonly used alloy tool steels.

1) Alloy Cutting Tool Steel. Alloy cutting tool steel is used to manufacture various cutting tools, such as lathe tools, milling cutters, drill bits, taps, dies, etc. The commonly used alloy cutting tool steels include low alloy cutting tool steel and high-speed tool steel.

Low alloy cutting tool steel typically has a carbon mass fraction (wC) of 0.75% to 1.45%. Its heat treatment process involves quenching and low-temperature tempering. The maximum working temperature of this type of steel does not exceed 300°C.

It is only used for manufacturing low-speed cutting tools or tools with high wear resistance requirements such as planers, taps, dies, drill bits, etc. Common grades of low alloy cutting tool steel include 9SiCr, CrWMn, and more.

High-speed tool steel is a type of high-carbon high-alloy steel, with a carbon mass fraction (wC) of 0.7% to 1.6%, and contains a large amount of W, Cr, Mo, V, and other alloying elements. The heat treatment of high-speed tool steel involves quenching followed by multiple high-temperature tempering, resulting in tempered martensite + carbide structure.

After normal tempering, the hardness is generally 63~66HRC, demonstrating good heat resistance. The tools made from high-speed tool steel still maintain a high hardness of about 60HRC under a cutting temperature of 600°C, hence they are suitable for high-speed cutting. Common grades include W18Cr4V, W6Cr5Mo4V2, and more.

Table 1-9: Examples of Common Alloy Tool Steel Grades, Heat Treatment Conditions, and Applications

| Types of Steel | Grades | Heat Treatment and Hardness | Example of Use | |||

| Quenching | Tempering | |||||

| Heating Temperature / ℃ | Hardness HRC | Heating Temperature / ℃ | Hardness HRC | |||

| Low-Alloy Tool Steel | 9SiCr CrWMn | 860~880 (Oil Quench) 820~840 (Oil Quench) | ≥62 ≥62 | 150~200 140~160 | 60~62 62~65 | Taps, Dies, Reamers, etc. |

| High-Speed Tool Steel | W18Cr4V W6Mo5Cr4V2 | 1280 (Oil Quench) 1220 (Oil Quench) | 60~65 ≥64 | 560 560 | 63~66 64~66 | Milling Cutters, Turning Tools, Drill Bits, Planers, etc. |

| Hot-Work Die Steel | 5CrNiMo 3Cr2W8V | 830~860 (Oil Quench) 1050~1100 (Oil Quench) | ≥47 >50 | 530~550 560~580 | 30~47 45~48 | Large Forging Dies, Hot Press Dies, Hot Shear Blades, Die Casting Dies, etc. |

| Cold-Work Die Steel | Cr12 Cr12MoV | 950~1000 (Oil Quench) 1020~1040 (Oil Quench) | 62~65 62~63 | 180~220 160~180 | 60~62 61~62 | Cold Punching Dies, Trimming Dies, Wire-Drawing Dies, Edging Dies, Beading Dies, etc. |

2) Alloy Die Steel. Alloy die steel is divided into hot-work die steel and cold-work die steel.

Hot-work die steel is used to manufacture various hot forging dies, hot extrusion dies, and die casting dies, etc., with the cavity surface temperature reaching above 600℃ during operation; cold-work die steel is used to manufacture various cold punching dies, cold heading dies, cold extrusion dies, and wire-drawing dies, etc., with the working temperature not exceeding 300℃.

Cold-work die steel has a carbon mass fraction wc ≥1.0% and the added alloying elements can strengthen the matrix, form carbides, and improve the hardness and wear resistance of the steel. After quenching and low-temperature tempering, cold-work die steel obtains a tempered martensite and granular carbide structure. Commonly used cold-work die steels include Cr12, Cr12MoV, etc.

The carbon mass fraction of hot-work die steel is generally 0.3%~0.6%, and the added alloy elements can improve the hardenability, heat resistance, and heat fatigue resistance of the steel.

After quenching and high-temperature tempering or medium-temperature tempering, hot-work die steel obtains a tempered sorbite or tempered troostite structure. Commonly used hot-work die steels include 5CrNiMo, 3Cr2W8V, etc.

(5) Special Performance Steels

Special performance steels refer to steels with unique usage properties. There are many types of special performance steels, but this section will only introduce commonly used ones in the mechanical industry: stainless steel, heat-resistant steel, and wear-resistant steel.

1) Stainless Steel.

Stainless steel refers to steel capable of resisting atmospheric or corrosive media. Common types include 12Cr13 martensitic stainless steel, 10Cr17 ferritic stainless steel, and 18-8 chromium-nickel austenitic stainless steel.

Martensitic stainless steel is often used for products requiring high mechanical properties and relatively low corrosion resistance; ferritic stainless steel is widely used in nitric acid, nitrogen fertilizer, phosphoric acid industries, and also as an oxidation-resistant material at high temperatures; austenitic stainless steel is the most widely used type of stainless steel in industry, but intergranular corrosion must be prevented.

2) Heat-Resistant Steel.

Heat-resistant steel refers to steel that maintains high chemical stability and thermal strength at high temperatures. Chemical stability refers to the ability of steel to resist various chemical corrosions at high temperatures, while thermal strength refers to the strength performance of steel at high temperatures.

Commonly used heat-resistant steels include pearlitic heat-resistant steel, martensitic heat-resistant steel, and austenitic heat-resistant steel.

Pearlitic heat-resistant steel operates at temperatures of 450-550°C and is primarily used for manufacturing parts with small loads in power devices, such as boiler steel tubes; martensitic heat-resistant steel operates at temperatures of 550-600°C and is mainly used for manufacturing turbine blades, diesel engine exhaust valves, etc.; austenitic heat-resistant steel operates at temperatures of 600-700°C, and can reach up to 850°C, and is primarily used for manufacturing jet engine turbines and exhaust pipes. Common heat-resistant steels include 12Cr1MoV, 42Cr9Si2, and 4Cr13Ni8Mn8MoVNb.

3) Wear-Resistant Steel.

Wear-resistant steel generally refers to high manganese steel that undergoes impact hardening under impact loads. Its main components are: w c =1.0%-1.3%, w Mn =11%-14%. It is cast into shape, and after heat treatment, it obtains an entirely austenitic structure, which exhibits good toughness and wear resistance.

Common high manganese steels include ZGMn13, ZGMn13Cr2, etc. High manganese steel is widely used in manufacturing parts that bear large impacts or pressures, such as excavator buckets, tank tracks, etc. Moreover, high manganese steel is not brittle in cold climates, making it suitable for use in frigid regions.

Non-ferrous Metals and Alloys

Aluminum and Aluminum Alloys

Pure aluminum has a silver-white color, a face-centered cubic crystal structure, and no allotropic transformation. It is characterized by a low melting point (660℃), low density (2.7g/cm3), low strength (σb=80MPa), high plasticity (ψ=80%), and excellent electrical and thermal conductivity.

As such, pure aluminum is not suitable for load-bearing structures. It is mainly used for manufacturing wires, cables, utensils with low strength requirements, and various aluminum alloys. Pure aluminum is chemically active and tends to form a sturdy and dense oxide film on its surface, providing it with good corrosion resistance in air and fresh water.

Aluminum alloys can be divided into deformed aluminum alloys and cast aluminum alloys based on their processing characteristics. Figure 1-41 shows a classification diagram of aluminum alloys. Alloys to the left of point D, when heated, exist as single-phase solid solutions with good plasticity, suitable for pressure processing.

These are referred to as deformed aluminum alloys. Alloys to the right of point D, which contain a larger mass fraction of alloying elements and have eutectic structures, feature lower melting temperatures and good fluidity, making them suitable for casting. These are referred to as cast aluminum alloys.

Deformed aluminum alloys are typically processed into various semi-finished products such as sheets, bars, tubes, wires, profiles, and forgings. Among the deformed aluminum alloys, Al-Mg and Al-Mn series alloys mostly have a single-phase structure and cannot be strengthened by heat treatment. They are characterized by good corrosion resistance, weldability, and plasticity, as well as excellent low-temperature performance.

These properties make them promising in fields such as aerospace. Al-Cu-Mg and Al-Cu-Mn series alloys have strong age-hardening capabilities and high strength, but their corrosion resistance and weldability are inferior. They are mainly used as structural components. Al-Mg-Cu-Zn series alloys have the highest room-temperature strength among aluminum alloys, but they soften quickly at high temperatures and have poor corrosion resistance.

They are primarily used for important structures and parts under heavy loads. Al-Mg-Si-Cu and Al-Cu-Mg-Fe-Ni series alloys have good thermoplasticity, castability, and relatively high mechanical properties. They are mainly used for complex aerospace and instrument parts and can also be used as heat-resistant alloys.

Al-Cu-Mg, Al-Cu-Mn, Al-Mg-Cu-Zn, Al-Mg-Si-Cu, and Al-Cu-Mg-Fe-Ni series aluminum alloys can all be strengthened by heat treatment. Examples of commonly used deformed aluminum alloys, their chemical composition, mechanical properties, and uses are given in Table 1-10.

Table 1-10: Examples of Commonly Used Deformed Aluminum Alloys, Including Their Designations, Chemical Compositions, Mechanical Properties, and Applications

| Category | Code | Chemical composition (%) | Heat treatment Theory | Mechanical properties | Examples of applications | |||||

| WCu | WMg | WMn | WZn | σb/MPa | δ(%) | Hardness HBW | ||||

| Rust-proof aluminum alloy | 5A05 | 4.5~5.5 | 0.3~0.6 | M | 270 | 23 | 70 | Medium load parts, rivets, and welded oil tanks, oil pipes, etc. | ||

| 3A21 | 1.0~1.6 | 130 | 23 | 30 | ||||||

| Hard aluminum alloy | 2A01 | 2.2~3.0 | 0.2~0.5 | CZ | 300 | 24 | 70 | Medium strength and working temperature below 100°C rivet material | ||

| 2A11 | 3.8~4.8 | 0.4~0.8 | 0.4~0.8 | 420 | 18 | 100 | Medium strength structural parts and components, such as frames, propeller blades, rivets, etc. | |||

| 2A12 | 3.8~4.9 | 1.2~1.8 | 0.3~0.9 | 470 | 17 | 105 | High strength components and parts working below 150°C, such as frames, beams, etc. | |||

| Super hard aluminum alloy | 7A04 | 1.4~2.0 | 1.8~2.8 | 0.2~0.6 | 5~7 | CS | 600 | 12 | 150 | Main load-bearing structures, such as aircraft beams, trusses, reinforcement frames, and landing gears, etc. |

| Forged aluminum alloy | 2A50 | 1.8~2.6 | 0.4~0.8 | 0.4~0.8 | 420 | 13 | 105 | Complex shapes and medium strength forgings and die forgings, etc. | ||

| 2A70 | 1.9~2.7 | 1.4~1.8 | 440 | 12 | 120 | Complex forgings and structural parts working at high temperatures, internal combustion engine pistons, etc. | ||||

| 2A14 | 3.9~4.8 | 0.4~0.8 | 0.4~1.0 | 480 | 19 | 135 | Simple shapes and high load forgings and die forgings, etc. | |||

Note: M—Annealing; CZ—Quenching + Natural aging; CS—Quenching + Artificial aging.

Copper and Copper Alloys

Pure copper has a density of 8.94g/cm³ and a melting point of 1083℃. It has a face-centered cubic crystal structure and no allotropy. Pure copper exhibits good electrical conductivity, thermal conductivity, and corrosion resistance. While pure copper has good ductility, its strength and hardness are low, making it unsuitable for direct use as a structural material.

It is often used to manufacture conductive and heat-conductive materials, corrosion-resistant devices, and it can also serve as a raw material for making copper alloys. Pure copper cannot be strengthened through heat treatment. Depending on the different chemical compositions, copper alloys can be divided into three categories: brass, bronze, and white copper.

(1) Brass

Copper alloys with zinc as the primary alloying element are referred to as brass. Depending on the chemical composition, brass can be divided into simple brass and special brass. Simple brass is a binary alloy of copper and zinc. When the mass fraction of zinc is between 30% and 32%, its structure is a face-centered cubic α solid solution, known as single-phase brass.

This type of brass has excellent forgeability, weldability, and good tin plating ability. When the mass fraction of zinc exceeds 32% (but not more than 45%), its structure is a α+β dual-phase structure, known as dual-phase brass.

This brass has good high-temperature ductility, suitable for hot processing. The designation of ordinary brass consists of “H+number”, where H stands for brass, and the number indicates the mass fraction of copper. For example, H80 is ordinary brass containing 80% copper and 20% zinc.

Special brass is formed by adding other alloy elements to the copper-zinc alloy. In addition to zinc, common alloy elements include lead, aluminum, manganese, tin, iron, nickel, silicon, etc. The addition of these alloy elements improves the strength, corrosion resistance, and wear resistance of the brass.

Depending on the primary alloy elements added, special brass can be divided into lead brass, aluminum brass, and manganese brass, etc. The designation of special brass consists of “H+ primary alloy element symbol + mass fraction of copper + mass fraction of primary alloy element”.

For example, HPb59-1 represents special brass with a mass fraction of 59% copper and 1% lead, with the remainder being zinc. The designations, chemical compositions, mechanical properties, and examples of applications of commonly used brass are shown in Table 1-11.

(2) Bronze

Bronze refers to copper alloys with major alloying elements other than Zn and Ni. Its designation is composed of “Q+ primary alloy element symbol + mass fraction of primary alloy element”. If it’s cast bronze, a “Z” is added before the designation. Bronze can be divided into ordinary bronze and special bronze.

Table 1-11: Representative Designations, Chemical Compositions, Mechanical Properties, and Example Applications of Commonly Used Deformed Aluminum Alloys

| Category | Grade | Chemical Composition (%) | Mechanical Properties | Application Examples | |||||||

| WCu | WPb | WSi | WAl | WMn | σb/MPa | δ(%) | Hardness HBW | ||||

| Common Brass | H90 | 88~91 | 320 | 52 | 53 | Coatings and Decorations, etc. | |||||

| H68 | 67~70 | 660 | 3 | 150 | Cartridge Cases, Condenser Tubes, etc. | ||||||

| H62 | 60.5~63.5 | 600 | 3 | 164 | Washers, Springs, Screws, etc. | ||||||

| Special Brass | Lead Brass | HPb59-1 | 57~60 | 0.8~1.9 | 650 | 16 | 140 | Pins, Screws, and other Stamped or Machined Parts | |||

| Aluminum Brass | HAl59-3-2 | 57~60 | 2.5~3.5 | 650 | 15 | 150 | High Strength, Chemically Stable Parts | ||||

| Manganese Brass | HMn58-2 | 57~60 | 1.0~2.0 | 700 | 10 | 175 | Parts for Ships and Weak Electric Use | ||||

Ordinary bronze refers to tin bronze, with tin (Sn) as the primary alloying element. The mass fraction of Sn is key to the performance of tin bronze. Tin bronze with a Sn mass fraction of 5% to 7% has the best plasticity, suitable for cold and hot deformation processing. Tin bronze with a Sn mass fraction exceeding 10% has high strength but poor plasticity, suitable only for casting.

Tin bronze exhibits excellent corrosion resistance in the atmosphere, seawater, and inorganic salt solutions but shows poorer corrosion resistance in ammonia, hydrochloric acid, and sulfuric acid.

Special bronze refers to bronze that does not contain Sn. Depending on the primary alloying element, it can be divided into aluminum bronze, beryllium bronze, silicon bronze, etc. Aluminum bronze has an aluminum mass fraction of 5% to 10%, high chemical stability, good corrosion and wear resistance, higher strength and plasticity, and good workability.

It is primarily used for high-strength wear-resistant parts working in seawater or high temperatures. Beryllium bronze has a beryllium mass fraction of 1.7% to 2.5%. It can undergo solution strengthening and age hardening, possessing high strength, wear resistance, corrosion resistance, and electrical and thermal conductivity.

It also has special properties such as antimagnetism and no spark generation upon impact, primarily used for elastic elements in precision instruments and explosion-proof parts in motors. Silicon bronze has a silicon mass fraction of 3% to 4.6%, with higher mechanical properties than tin bronze and good casting and cold/hot processing performance.

Adding nickel to silicon bronze can significantly improve its strength and wear resistance, mainly used in the aviation industry and long-distance overhead telephone lines, power lines, etc. The brand number, chemical composition, mechanical properties, and example applications of commonly used bronze can be seen in Table 1-12.

(3) Nickel Silver

Nickel silver, also known as white copper, refers to a category of copper alloys primarily composed of nickel. It is divided into two types: ordinary nickel silver and special nickel silver.

Table 1-12: Examples of Common Bronze Grades, Chemical Compositions, Mechanical Properties, and Uses

| Category | Grade | Chemical composition (%) | Mechanical properties | Example uses | ||||||

| WSn | WAl | WSi | Others | σb/MPa | δ(%) | Hardness | ||||

| Ordinary bronze | QSn4-3 | 3.5~4.5 | Zn: 2.7~3.3 | 350~550 | 4~40 | 60~160 HBW | Elastic elements, wear-resistant, anti Magnetic components | |||

| QSn6.5-0.1 | 6.0~7.0 | P: 0.10~0.25 | 350~450 | 60~70 | 70~90 HBW | Contact pieces, springs, wear-resistant parts | ||||

| Special bronze | Beryllium bronze | QBe2 | Be:1.8~2.1 Ni:0.2~0.5 | 500~850 | 3~40 | 90~250 HV | Important springs, elastic elements Bearings, etc. | |||

| Silicon bronze | QSi3-1 | 2.7~ 3.5 | Mn: 1~1.5 | 80~180 HV | Springs and parts working in corrosive media | |||||

Ordinary nickel silver, containing only copper and nickel, possesses good strength and excellent plasticity. It can undergo both cold and hot pressure processing. Its corrosion resistance is excellent, and it has a high electrical resistivity with a small temperature coefficient of resistance.

It is primarily used for manufacturing ship instrument parts, chemical machinery parts, and medical equipment, among others. The grade of nickel silver is composed of “B + average mass fraction of Ni”. For example, B19 represents ordinary nickel silver with a nickel content of 19%.

Special nickel silver is produced by adding other alloy elements to nickel silver. The properties and uses of nickel silver vary depending on the type of alloy element added. For instance, manganese nickel silver with a high mass fraction of manganese can be used to manufacture thermocouple wires, measuring instruments, etc. For example, BZn15-20 represents special nickel silver with a silicon content of 15% and a zinc content of 20%.

Titanium and Titanium Alloys

Pure titanium has a density of 4.5g/cm³ and a melting point of 1667°C, undergoing allotropy. Below 882.5°C, pure titanium has a close-packed hexagonal crystal structure, known as α-Ti. Above 882.5°C, it has a body-centered cubic crystal structure, referred to as β-Ti.

Pure titanium (α-Ti) has a relatively low modulus of elasticity, good impact resistance, high specific strength, and excellent plasticity, but its mechanical properties are extremely sensitive to impurities.

The main characteristics of titanium alloys are high strength, low density, good heat resistance, and corrosion resistance. However, they have poor machinability, are wear-sensitive, and are relatively expensive. Titanium alloys are categorized into α-type (TA), β-type (TB), and α+β type (TC) based on their annealed structures.

Examples of grades, chemical compositions, mechanical properties, and uses of commonly used titanium alloys are shown in Table 1-13.

(1) α-Type Titanium Alloys

The annealed structure of α-type titanium alloys is a single-phase α solid solution, and they cannot be strengthened by heat treatment. These alloys have stable structures, excellent corrosion resistance, good plasticity, and formability. They also exhibit excellent welding performance and low-temperature properties.

They are commonly used to manufacture aircraft skins, frames, engine compressor discs and blades, turbine casings, and ultra-low temperature containers.

Table 1-13: Examples of Commonly Used Titanium Alloys, Their Chemical Compositions, Mechanical Properties, and Applications

| Category | Grade | Chemical composition group | Heat treatment | Room temperature mechanical properties | High temperature mechanical properties | Examples of use | |||

| σb/MPa | δ(%) not less than | Test temperature/℃ | Instantaneous Strength /MPa | Endurance strength ① /MPa | |||||

| Alpha titanium alloy | TA28 | Ti-3Al | Annealing | 700 | 12 | Working below 500℃ Parts such as missile fuel Tanks, aircraft turbine casings, etc. | |||

| TA5 | Ti-4Al-0.005B | Annealing | 700 | 15 | |||||

| TA6 | Ti-5Al | Annealing | 700 | 12~20 | 350 | 430 | 400 | ||

| Beta titanium alloy | TB2 | Ti-5Mo-5V-8Cr-3Al | Quenching | 1000 | 20 | Working below 350℃ Parts such as compressor blades Shafts, disks, and other heavy-load rotating parts, aircraft components, etc. | |||

| Quenching + aging | 1350 | 8 | |||||||

| Alpha + beta titanium alloy | TC1 | Ti-2Al-1.5Mn | Annealing | 600~800 | 20~25 | 350 | 350 | 350 | Working below 400℃ Parts such as engine components with certain high temperature strength; low temperature rocket, missile liquid hydrogen fuel tanks, etc. |

| TC2 | Ti-4Al-1.5Mn | Annealing | 700 | 12~15 | 350 | 430 | 400 | ||

| TC3 | Ti-5Al-4V | Annealing | 900 | 8~10 | 500 | 450 | 200 | ||

| TC4 | Ti-6Al-4V | Annealing | 950 | 10 | 400 | 630 | 580 | ||

| Quenching + Aging | 1200 | 8 | |||||||

①持久强度表示材料在给定温度下经过100h后,试样发生断裂时的应力值。

(2) Beta Titanium Alloys

Beta titanium alloys have a beta phase annealed structure. By quenching, metastable beta phase titanium alloys can be obtained. These alloys can be heat-treated to enhance their strength, have high room temperature strength, and good cold forming properties. However, these alloys have a high density, their structure is not stable enough, and they have poor heat resistance. Beta titanium alloys are mainly used to manufacture aircraft components that do not require high temperatures but need high strength, such as springs, fasteners, and thick-section components.

(3) Alpha + Beta Titanium Alloys

The annealed structure of alpha + beta titanium alloys is the (alpha + beta) phase, combining the characteristics of alpha and beta titanium alloys. They have excellent comprehensive mechanical properties and are the most widely used titanium alloys. For instance, TC4 (Ti-6Al-4V) is widely used in aerospace and other industrial sectors.