Table 1 Basic Symbols, Pipelines, and Connections (GB/T 786.1—2009)

| Name | Symbol |

| Oil Supply and Return Lines |  |

| Control Lines, Drain Lines, Flushing Lines, and Vent Lines |  |

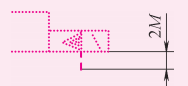

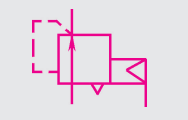

| Combination Component Outline | |

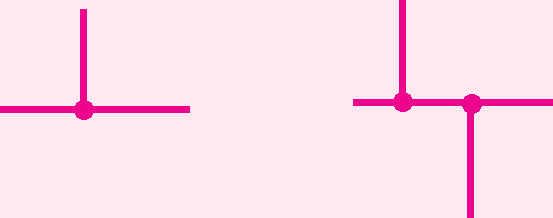

| Connection of Two Fluid Lines |  |

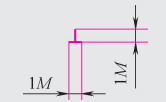

| Connecting Line |  |

| Crossing Line | |

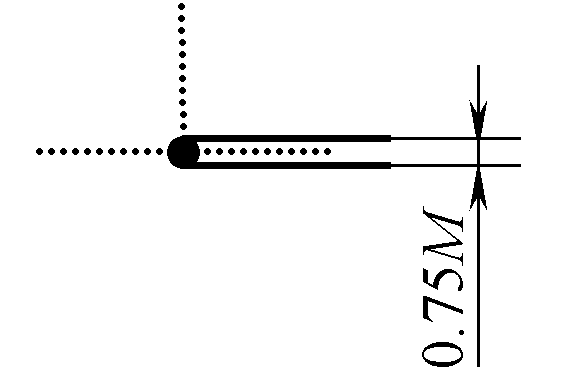

| Hose Assembly |  |

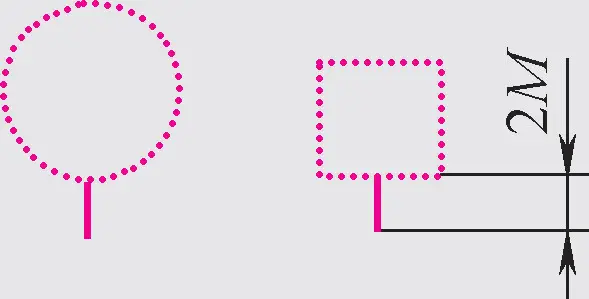

| Interface |  |

| Control Line or Drain Line Interface |  |

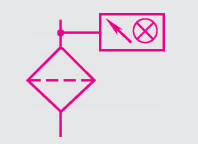

| Closed Line or Interface |  |

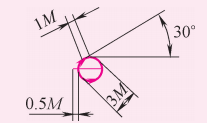

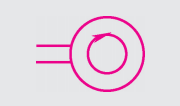

| Rotary Joint |  |

| Three-Way Plug Valve |  |

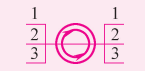

| Three-Way Rotary Joint |  |

| Quick-Disconnect Coupling without Check Valve, Disconnected State | |

| Quick-Disconnect Coupling with Check Valve, Disconnected State | |

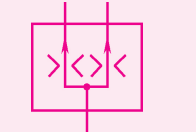

| Quick-Disconnect Coupling with Two Check Valves, Disconnected State |

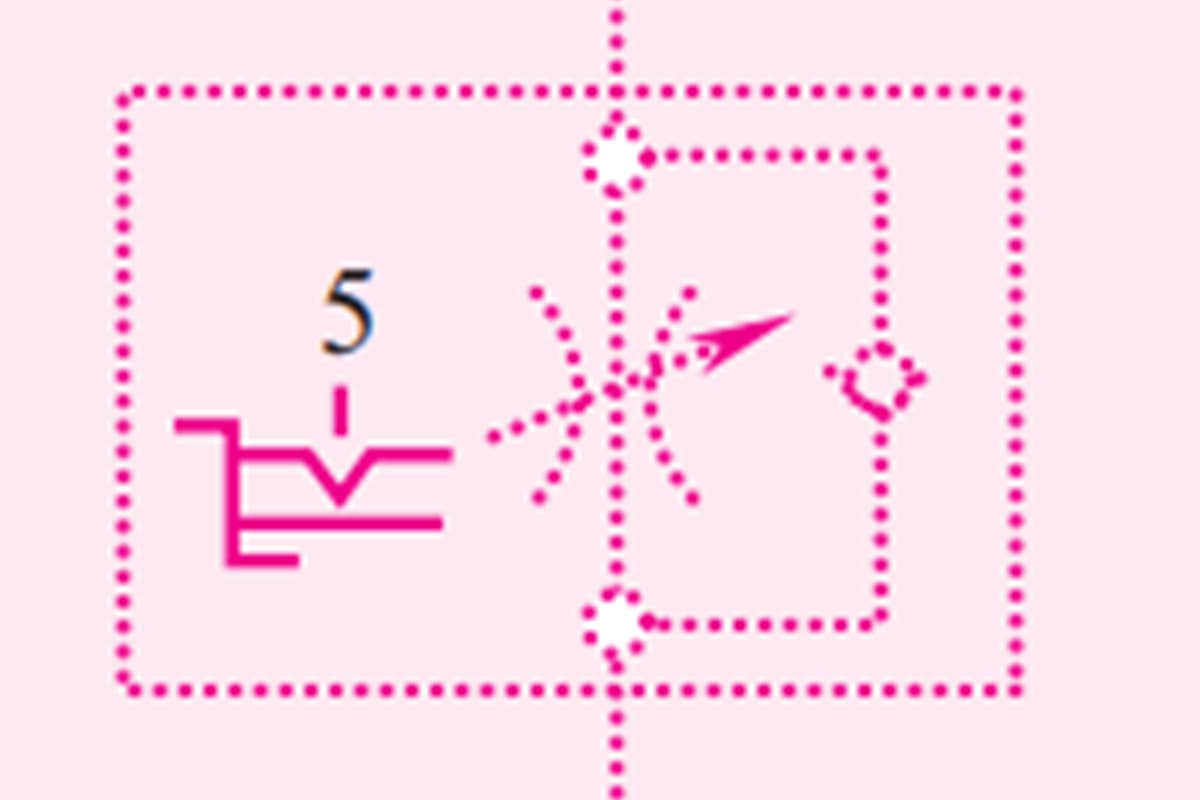

Table 2 Control Structures and Control Methods

| Name | Symbol |

| Control Mechanism with Separate Handle and Positioning Pin |  |

| Push Rod with Adjustable Stroke Limiter |  |

| Push or Pull Control Mechanism with Positioning Device |  |

| Manual Locking Control Mechanism |  |

| Control Mechanism with 5 Locking Positions |  |

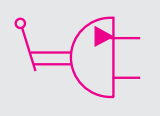

| Roller Lever for Single Stroke Direction Operation |  |

| Control Mechanism with Stepper Motor |  |

| Single-acting solenoid, action towards the valve core |  |

| Single-acting solenoid, action away from the valve core |  |

| Double-acting electrical control mechanism, action towards or away from the valve core |  |

| Electrically operated pneumatic pilot control mechanism |  |

| Electrically operated hydraulic pilot control mechanism with external oil supply |  |

| Mechanical feedback |  |

| Pneumatic reset, pressure supplied from the valve inlet |  |

| Pneumatic reset, external pressure source |  |

| Double-acting electrical control mechanism, action towards or away from the valve core, continuous control |  |

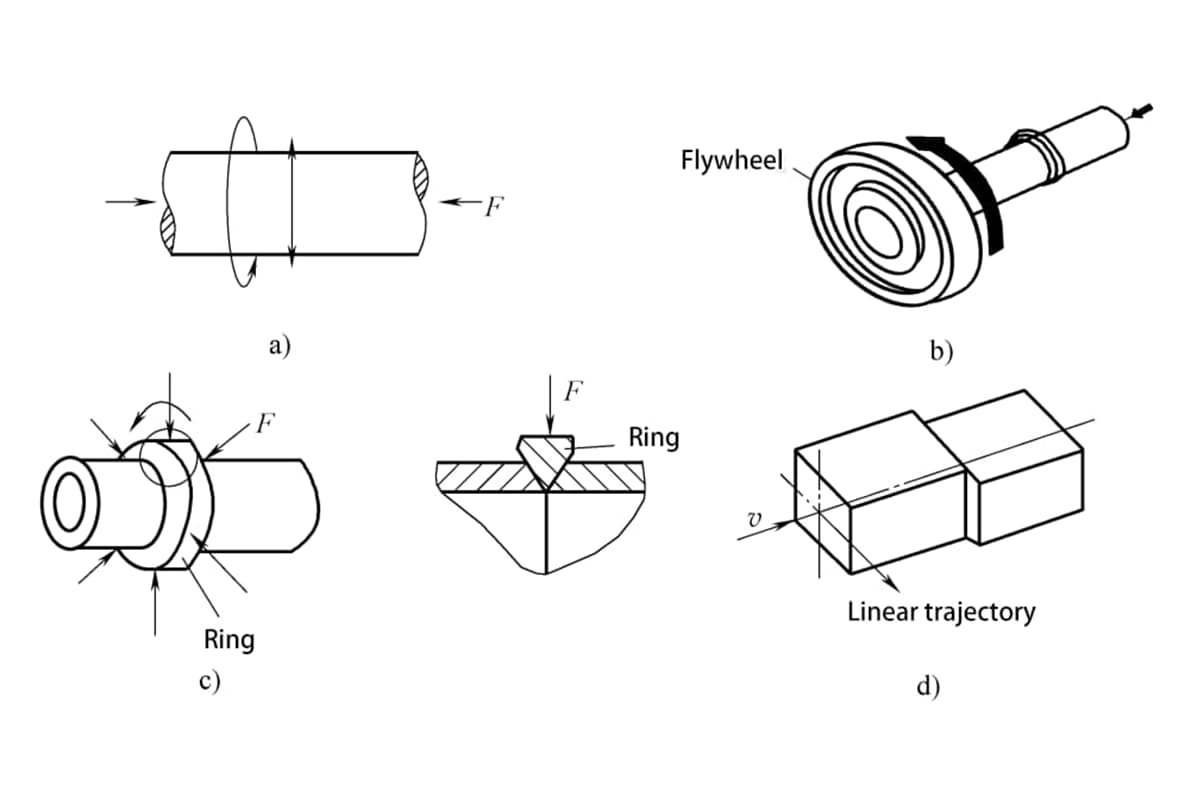

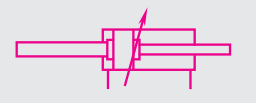

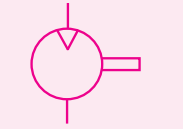

Table 3 Pumps, Motors, and Cylinders

| Name | Symbol |

| Variable pump |  |

| Bidirectional flow, variable pump with external leakage oil path and unidirectional rotation |  |

| Fixed displacement pump or motor with unidirectional rotation |  |

| Joystick control, pump with restricted disc angle |  |

| Swing actuator or rotary drive with restricted swing angle, bidirectional flow |  |

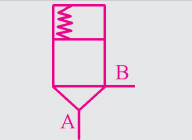

| Single-acting single-rod cylinder, return stroke by spring force |  |

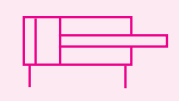

| Double-acting single-rod cylinder |  |

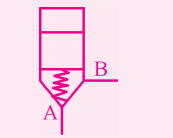

| Single-acting cylinder, plunger cylinder |  |

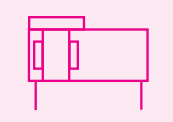

| Double-acting band-type rodless cylinder, with end cushioning on both ends of the piston |  |

| Double-acting double-rod cylinder, different piston rod diameters, cushioning on both sides, adjustable on the right side |  |

| Single-acting clamp with permanent magnet piston |  |

| Motor |  |

| Air compressor |  |

| Vacuum pump |  |

| Bidirectional swing motor with fixed flow rate and direction change |  |

| Single-acting semi-rotary cylinder or swing motor |  |

| Single-acting telescopic cylinder |  |

| Double-acting telescopic cylinder |  |

| Double-acting cylinder with end-of-stroke positioning |  |

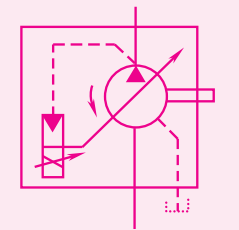

| Electro-hydraulic servo-controlled variable hydraulic pump |  |

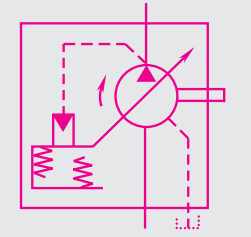

| Variable pump with constant power control |  |

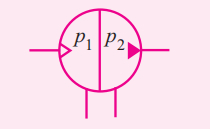

| Continuous booster, converts gas pressure p 1 to liquid pressure p 2 |  |

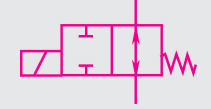

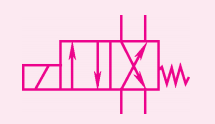

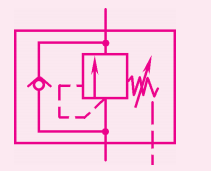

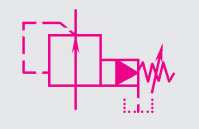

Table 4 Control elements

| Name | Symbol |

| Two-way two-position directional control valve, two-way two-position, push control mechanism, spring return, normally closed |  |

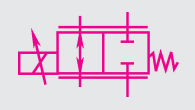

| Two-way two-position directional control valve, two-way two-position, solenoid operated, spring return, normally open |  |

| Two-way four-position directional control valve, solenoid operated, spring return |  |

| Two-way three-position directional control valve, solenoid operated, spring return, normally closed |  |

| Relief valve, direct-acting, opening pressure adjusted by spring |  |

| Sequence valve, manually adjustable setpoint |  |

| Sequence valve with bypass valve |  |

| Two-way pressure reducing valve, pilot-operated, external drain type |  |

| Three-way pressure reducing valve (hydraulic) |  |

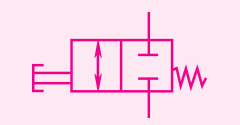

| Adjustable flow control valve |  |

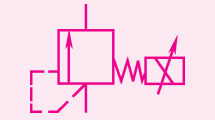

| Adjustable flow control valve, unidirectional free flow |  |

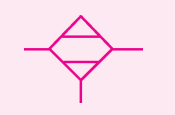

| Flow divider, splits input flow into two output streams |  |

| Check valve, allows free flow in one direction only |  |

| Double check valve, pilot-operated |  |

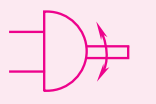

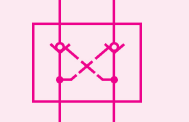

| Shuttle valve (“OR” logic), automatically connects the higher pressure inlet to the outlet |  |

| Proportional relief valve, direct-acting, controls hydraulic solenoid directional seat valve by adjusting spring length via solenoid |  |

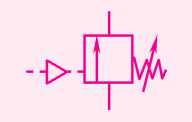

| Proportional flow control valve, direct-acting |  |

| Proportional directional control valve, direct control |  |

| Pressure and directional control cartridge valve insert, valve seat structure area 1:1 |  |

| Pressure and directional control cartridge valve insert, normally open, valve seat structure, area 1:1 |  |

| Proportional relief valve, pilot control, with solenoid position feedback |  |

| Externally controlled sequence valve |  |

| Internally reversible pressure regulating valve |  |

| Pressure reducing valve, remote pilot, adjustable, forward flow only |  |

| Quick exhaust valve |  |

| Double pressure valve (“AND” logic), and only when both inlets have pressure will a weaker signal be output from the outlet |  |

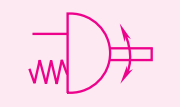

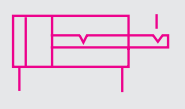

Table 5 Auxiliary components

| Name | Symbol |

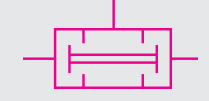

| Filter |  |

| Tank breather filter |  |

| Filter with auxiliary magnetic core |  |

| Filter with optical blockage indicator |  |

| Cooler without coolant flow indicator |  |

| Liquid-cooled cooler |  |

| Heater |  |

| Temperature regulator |  |

| Tachometer |  |

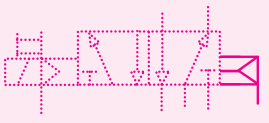

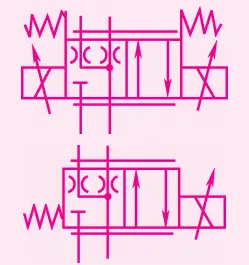

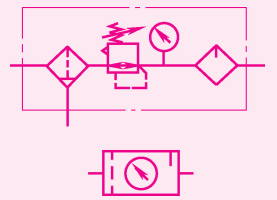

| Air source treatment device, including manual drain filter, manually adjustable overflow pressure reducing valve, pressure gauge, and oil mist separator. (The above is a detailed schematic, the below is a simplified diagram) |  |

| Oil mist separator |  |

| Air dryer |  |

| Oil mist lubricator |  |

| Single-acting pressure medium converter, converts gas pressure to equivalent liquid pressure, and vice versa |  |

| Diaphragm type gas accumulator |  |

| Piston type gas accumulator |  |

| Gas cylinder |  |

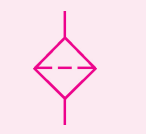

| Pressure gauge |  |

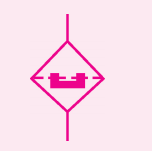

| Differential pressure gauge |  |

| Thermometer |  |

| Liquid level indicator |  |

| Flow indicator |  |

| Flow meter |  |

| Lubrication point |  |

| Vacuum separator |  |

| Manual drainage fluid separator |  |

| Vacuum generator |  |

| Air tank |  |