There are many types of materials used in sheet metal production and processing, with specifications mainly focusing on sheet and profile materials. Common non-metallic materials include cardboard, bakelite board, rubber board, plastic board, composite board, etc. Rubber board has good elasticity, wear resistance, low-temperature resistance, and insulation properties, and can be used as elastic material, sealing material, and vibration damping material, etc.

Due to the high strength, good plasticity, toughness, and wear resistance of engineering plastic boards, they can replace metals in making sheet metal parts, especially those with a high specific strength (the ratio of tensile strength to density), such as glass fiber reinforced plastics, which can greatly exceed the specific strength of metals and are widely used in making sheet metal structural parts to reduce weight.

In addition, most engineering plastics have good corrosion resistance to media such as acids, alkalis, and salts. Among them, polytetrafluoroethylene and rigid polyvinyl chloride have excellent resistance to strong acids and alkalis, so they can be used to make chemical corrosion-resistant parts, corrosion-resistant linings, heat exchanger parts, chemical pipelines, and elbows, etc.

Table 1 lists the names, grades, properties, and applications of common non-metallic material boards.

Table 1 Names, grades, properties, and applications of non-metallic material boards

| Material Name | Grade | Properties and Description | Application |

| Oil-resistant asbestos rubber board | NBR | Made of nitrile rubber synthetic board, with good oil resistance, thickness of 0.4~3.0mm | Used for sealing gaskets in sheet metal products, such as oil pipelines, oil storage tanks Sealing rings, etc. |

| Acid and alkali resistant rubber board | SBR2030 SBR2040 | Made of styrene-butadiene rubber, with cold resistance, medium temperature resistance, and aging resistance, etc. | Used for sealing gaskets working in -30~60℃, with a volume fraction of 20% acid and alkali solution |

| Oil-resistant rubber board | NBR3001 NBR3002 | Made of nitrile rubber board, with good oil resistance | Used for gaskets working in certain temperatures of engine oil, transformer oil, gasoline, etc. Organic solutions |

| Heat-resistant rubber board | SBR4001 SBR4002 | Made of styrene-butadiene rubber, with cold resistance, high-temperature resistance, and aging resistance, etc. | Used for gaskets and thermal insulation pads working in -30~100℃, with low-pressure hot air and steam media |

| Phenolic laminated board | PF3302-1 PF3302-2 | Made of laminated phenolic plastic, with high strength, good impact resistance, and wear resistance | Used as structural parts for automotive brake pads, electrical switch boxes, telephone housings, etc. |

| Polytetrafluoroethylene board | F-4-13 | Good resistance to strong acid and alkali corrosion, excellent friction reduction and self-lubrication, can withstand temperatures below 250℃ | Used for lining containers holding corrosive media, heat exchanger sealing gaskets, etc. |

| Industrial organic glass | PC | PC is polycarbonate, known as “transparent metal”, with good electrical insulation and weather resistance, etc. | Used for transparent organic glass instruments working at -60~120℃ temperatures, etc. |

| Industrial flat felt | 112-44 232-36 | Thickness of 1~40mm, 112-44 indicates white fine felt, 232-36 indicates gray coarse felt | Used as sealing, oil leakage prevention, vibration damping, and cushioning pads for sheet metal structures, selecting fine, coarse, or semi-coarse felt as needed |

Although non-metallic materials are widely used in sheet metal structures, metal materials are still the most used in sheet metal production and processing, which are divided into ferrous and non-ferrous metal materials.

I. Ferrous Materials

Ferrous materials are iron-carbon alloys with iron as the matrix. Generally, iron-carbon alloys with a carbon mass fraction greater than 2.11% are called cast iron, and those with a carbon mass fraction less than 2.11% are called steel. Ferrous materials mainly include carbon steel, alloy steel, cast iron, and cast steel.

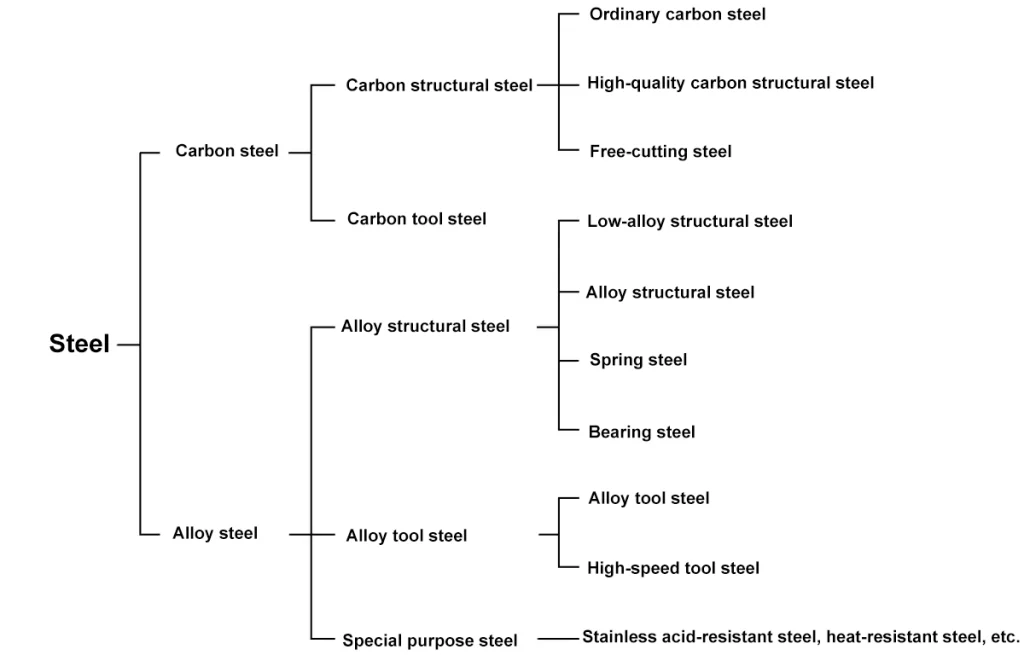

There are many classification methods for steel, which can be classified according to the steelmaking method, steel quality, chemical composition, or according to different metallographic structures and uses. Considering these factors comprehensively, steel can generally be classified as shown in Figure 1.

The most commonly used in sheet metal products are low carbon structural steel, low alloy structural steel, and special performance structural steel. The composition, performance, specifications, and application range of each type of steel are introduced as follows.

1. Low Carbon Structural Steel

Low carbon structural steel can be abbreviated as low carbon steel. According to the mass fraction of harmful impurities such as sulfur and phosphorus, it can be divided into ordinary low carbon steel, high-quality low carbon steel, and high-grade high-quality low carbon steel; according to its rolling state, it can be divided into hot-rolled and cold-rolled plates; according to its post-rolling treatment state, it can be divided into ordinary low carbon steel and coated low carbon steel. Low carbon steel is usually numbered according to composition and quality.

The mass fraction of sulfur in ordinary low carbon steel S is ≤0.055%, and the mass fraction of phosphorus P is ≤0.045%. Its grade can reflect mechanical properties; the mass fraction of sulfur and phosphorus in high-quality low carbon steel S, P is ≤0.040%; while the mass fraction of sulfur in high-grade high-quality low carbon steel S is ≤0.030%, and phosphorus P is ≤0.035%. Its grade can reflect the mass fraction of carbon, represented by two digits indicating the average mass fraction of carbon. The classification and numbering method of low carbon structural steel is shown in Table 2.

Table 2 Classification and Numbering Method of Low Carbon Structural Steel

| Classification | Example | Numbering Explanation |

| Ordinary Low Carbon Structural Steel | Q235AF Q235B Q235C Q235D | “Q” is the initial of the Chinese pinyin for “yield”, and the number following it is the yield strength (MPa). A, B, C, D represent quality grades, from left to right, the quality improves sequentially. F, b, Z, TZ represent boiling steel, semi-killed steel, killed steel, and special killed steel, respectively, but killed steel is not marked. Therefore, if there is no letter mark after the quality grade, it indicates killed steel, such as “Q235A” represents ordinary carbon structural steel, σs=235MPa, quality grade A killed steel |

| High-Quality Low Carbon Structural Steel | 08F, 10F, 15, 20 | Two digits represent the average mass fraction of carbon, in units of 0.01%, such as 08F represents boiling high-quality low carbon structural steel with an average mass fraction of carbon of 0.08%; 20 represents high-quality low carbon structural steel with an average mass fraction of carbon of 0.20% |

(1) Ordinary Low Carbon Structural Steel

Ordinary low carbon structural steel is usually used after hot rolling, in annealed or normalized state, generally without heat treatment. Most are used in hot-rolled or normalized state after hot rolling. If there are special needs, some corresponding annealing, normalizing, or quenching heat treatments can also be performed. The main components, performance characteristics, and applications of commonly used ordinary low carbon structural steel are shown in Table 3.

Table 3 Main Components, Performance Characteristics, and Applications of Commonly Used Ordinary Low Carbon Structural Steel

| Material Grade | Grade | w(C)(%) | w(Mn)(%) | σs/MPa≥ | σb/MPa≥ | δ5(%)≥ | Performance Characteristics and Applications |

| Q195 | — | 0.06~0.12 | 0.25~0.50 | 195 | 315~390 | 33 | High elongation, good weldability and toughness, mainly used to manufacture metal processing parts and welded parts with low requirements, such as chimneys, roofing panels, steel Wire mesh, etc. |

| Q215 | A | 0.09~0.15 | 0.25~0.55 | 215 | 335~410 | 31 | |

| B | |||||||

| Q235 | A | 0.14~0.22 | 0.30~0.65 | 235 | 375~460 | 26 | Certain elongation and strength, good toughness and castability, suitable for stamping and welding, widely used. Mainly Used to manufacture various types of steel sections, medium and thick plates for steel structures, chemical container shells, flanges, etc. |

| B | 0.12~0.20 | 0.30~0.70 | |||||

| C | ≤0.13 | 0.35~0.80 | |||||

| D | ≤0.17 |

(2) High-Quality Low Carbon Structural Steel

High-quality low carbon structural steel guarantees both chemical composition and mechanical properties upon delivery, and is more strictly regulated than ordinary carbon structural steel. The mass fraction of sulfur and phosphorus should be controlled below 0.35%, with fewer non-metallic inclusions and higher quality levels, generally used after heat treatment (except for container-specific steel, such as 20R).

High-quality carbon structural steel uses two Arabic numerals to represent the average mass fraction of carbon in ten-thousandths, with F added for boiling steel and no letter for killed steel. For example, “45” represents high-quality carbon structural steel with a carbon mass fraction of 0.45%, killed steel. The performance indicators, main characteristics, and applications of commonly used high-quality low carbon structural steel are shown in Table 4.

Table 4 Performance Indicators, Main Characteristics, and Applications of Commonly Used High-Quality Low Carbon Structural Steel

| Material Grade | σb/MPa | σs/MPa | δ5(%) | ψ(%) | Delivery State Hardness HBW≤ | Main Characteristics and Applications |

| 08F | 295 | 175 | 35 | 60 | 131 | Generally used to manufacture large deformation stamping parts and welded parts, such as shells, boxes, covers, fixed baffles, etc. Generally used without heat treatment, cold processing can increase strength. To refine the steel structure, eliminate internal stress caused by cold processing, and improve the cutting performance of steel, heat treatment strengthening is also required |

| 10F | 315 | 185 | 33 | 55 | 137 | Good plasticity and weldability. Mainly used for parts requiring good plasticity, such as pipes, gaskets, washers, etc., and carburized parts with low core strength requirements, such as sleeves, brackets, templates, gears, clutches, etc. |

| 15F | 355 | 205 | 29 | 55 | 143 | Good plasticity, toughness, weldability, and stamping performance, but low strength. Used to manufacture parts with low stress and high toughness requirements, carburized parts, fasteners, and die forgings, as well as low-load parts that do not require heat treatment, such as bolts, screws, flanges |

| 08 | 325 | 195 | 33 | 60 | 131 | This steel has low strength, very high cold deformation plasticity, good stamping, deep drawing, and bending performance, excellent weldability, sometimes sensitive to aging, better cutting performance in cold drawn or normalized state than in annealed state. Can be used to manufacture stamping parts and welded parts, etc. |

| 10 | 335 | 205 | 31 | 55 | 137 | This steel has a low yield strength to tensile strength ratio, good plasticity and toughness, easy to mold in cold state. To achieve the best deep drawing performance, the sheet should be normalized or high-temperature tempered; better cutting performance in cold drawn or normalized state than in annealed state; no temper brittleness tendency, good weldability. Used to manufacture low-strength welded parts, stamping parts, etc., such as partitions, shells, gaskets, etc. High cold deformation plasticity, generally used for bending, deep drawing, flanging, etc. To achieve the best deep drawing performance, the sheet should be normalized or high-temperature tempered, good weldability for arc welding and resistance welding, prone to cracks during gas welding on small thickness, strict shape requirements, or complex shaped parts, better cutting performance in cold drawn or normalized state than in annealed state |

| 20 | 410 | 245 | 25 | 55 | 156 | (3) Coated Low Carbon Structural Steel |

Coated low carbon steel sheet, commonly known as tinplate, is made by coating a layer of zinc, tin, lead, aluminum, or other non-ferrous metal materials on cold-rolled or hot-rolled thin steel sheets. Therefore, it can be divided into thin zinc plates, thin tin plates, thin lead plates, and thin aluminum plates, etc., according to different coatings.

Thin zinc plates are also commonly known as white zinc plates. The surface is bright white and comes in two types: smooth and corrugated. Both have strong corrosion resistance and an attractive appearance. These plates are suitable for making anti-corrosion containers, ceilings, and house water pipelines.

Thin tin plates have a bright and attractive surface, suitable for making food containers and cans. Thin lead plates, also known as white lead plates, also have strong corrosion resistance and are suitable for making acid-resistant containers. However, due to the toxicity of lead, they cannot be used for food containers.

2. Low alloy structural steel

Low alloy structural steel, often abbreviated as low alloy steel, is made by adding alloying elements not exceeding 2% or 3% by mass fraction to ordinary low carbon steel to enhance its strength. It is mainly used for various engineering structural components, with the widest range of applications and the largest consumption. It is usually used in the annealed or normalized state after hot rolling, without further heat treatment.

Low alloy steel can be divided into ordinary low alloy steel, container (including high temperature) low alloy steel, low temperature low alloy steel, etc., based on its use. Except for ordinary low alloy steel, the numbering method generally uses “number + element symbol + number,” where the front number represents the ten-thousandth of the average mass fraction of carbon in the steel, the element symbol represents the alloying element, and the number after the symbol represents the average mass fraction of that element in the steel.

The content of alloying elements is marked after the element symbol and is expressed as a percentage of the element’s mass fraction, but the decimal is converted to an integer.

If the average mass fraction of an alloying element is less than 1.5%, its content is not marked; if the average mass fraction is equal to or greater than 1.5%, 2.5%, 3.5%, etc., it is correspondingly represented by 2, 3, 4, etc. For example, “12Cr2Ni4” indicates that the main component mass fractions of the alloy steel are C 0.12%, Cr 1.5%, and Ni 3.5%.

If it is container steel, an “R” is added after the grade to indicate it, and if it is used at low temperatures, “DR” is used. For example, 16MnDR indicates low-temperature container steel with a carbon mass fraction of 0.16%, a Mn mass fraction of less than 1.5%, and containing small amounts of alloying elements such as V, Ti, and Nb.

(1) Ordinary low alloy steel

The carbon mass fraction in ordinary low alloy steel is 0.10% to 0.25%, and the mass fraction of alloy elements such as Mn, Si, V, Ti, Nb, Cu, P, and RE is generally less than 3%.

Among them, Mn and Si elements have a solid solution strengthening effect on ferrite and increase strength, V, Ti, and Nb elements can refine grains and improve toughness, Cu and P elements can enhance corrosion resistance, and rare earth elements RE are beneficial for deoxidation, desulfurization, and purifying harmful impurities in steel, which can improve the performance of steel.

The numbering method for ordinary low alloy steel is the same as that for ordinary low carbon steel, consisting of three parts in sequence: the Chinese pinyin letter representing yield strength (Q), the yield strength value, and the quality grade symbol (A, B, C, D, E), such as Q345C.

The yield strength of ordinary low alloy steel is 25% to 50% higher than that of low carbon steel, especially the yield strength ratio (σs/σb) is significantly improved. It also has good plasticity, toughness, weldability, and relatively good wear resistance and corrosion resistance. Table 5 shows the mechanical properties and applications of some low alloy structural steels.

Table 5 Mechanical properties and applications of some low alloy structural steels

| Grade/MPa | Grade (two representations) | Steel thickness Thickness/mm | Mechanical properties | Application | ||

| σb/MP | σs/MPa | δ5 | ||||

| 300 | Q295(A, B) (09MnNb)① | ≤16 | 410~560 | ≥295 | ≥24 | Ships, low-pressure boilers, containers, bridges, vehicles |

| >16~25 | 390~540 | ≥275 | ≥23 | |||

| 350 | Q345(A~E) (16Mn, 16MnRE) | ≤16 | 510~660 | ≥345 | ≥22 | Ships, bridges, large steel structures, building structures, chemical containers |

| >16~25 | 490~640 | ≥325 | ||||

| 400 | Q390(A~E) (16MnNb)① | ≤16 | 530~680 | ≥390 | ≥20 | Bridges, port engineering structures, ships, vehicles, chemical containers |

| >16~20 | 510~660 | ≥375 | ≥19 | |||

① The grades in parentheses are the old standard representation methods.

(2) Container low alloy steel

Container low alloy steel belongs to low alloy high strength steel. It is strengthened to C-Mn steel by adding Mn-Si on the basis of 20 steel and by adding V, N, Nb, Mo, etc., on the basis of 16Mn steel, making the steel very strong.

The steel plates recommended for steel pressure vessels mainly include 16MnR, 15MnVR, 18MnMoNbR, 13MnNiMoNbR, 07MnCrMoVR, etc., and the steel pipes are 16Mn, 15MnV, etc.

16MnR has good comprehensive mechanical properties, weldability, processability, and low-temperature impact toughness, but it is more prone to cracking during welding than low carbon steel. It is mainly used for manufacturing medium and low-pressure pressure vessel shells and pressure-bearing components, liquefied petroleum gas cylinders, and small and medium-sized spherical tanks at -20 to 400°C.

15MnVR, 15MnVNR, and 18MnMoNbR have higher strength, but their plasticity and toughness are lower than C-Mn steel. They have higher notch sensitivity and aging sensitivity, poor weldability, and strict process requirements. They are mainly used for manufacturing large storage tanks and high-pressure vessel pressure-bearing shells, ammonia synthesis towers, and urea synthesis towers that withstand temperatures ≤470°C and higher pressures.

07MnCrMoVR has high strength, high toughness, and excellent weldability. For plate thickness t≤50mm, welding can be done without preheating or with slight preheating, without causing welding cold cracks. It is mainly used for manufacturing high-parameter spherical containers, such as 1000 to 2000mm3 oxygen, nitrogen, hydrogen, liquefied petroleum gas, ethylene, and other normal and low-temperature spherical tanks.

(3) Low-temperature low alloy steel

Materials generally used at temperatures below 0°C are called low-temperature materials. Low-temperature metal materials commonly use low alloy steel, nickel steel, chromium-nickel austenitic steel, titanium alloy, and aluminum alloy. Common low-temperature low alloy manganese steel uses manganese as the main added element to improve the low-temperature toughness of the steel. Carbon-manganese-nickel steel uses manganese and nickel as the main added elements to further enhance its low-temperature toughness.

Carbon-manganese-nickel steel has better low-temperature toughness than low carbon steel. 9Ni steel is high-nickel austenitic steel with high strength and good low-temperature performance, having good plasticity, toughness, and workability at low temperatures. Table 6 shows the mechanical properties and applications of commonly used low-temperature steels.

Table 6 Mechanical properties and applications of commonly used low-temperature steels

| Category | Grade | Room temperature mechanical properties | Heat treatment | Application | ||

| σb/MPa≥ | σs/MPa≥ | δ5(%)≥ | ||||

| Carbon-manganese steel | 16MnDR | 450 | 255 | 21 | Normalizing or tempering | Steel plates used at -40°C, with S and P mass fractions lower than 16MnR, and good low-temperature toughness |

| 09Mn2VDR | 430 | 270 | 22 | Steel plates and pipes used at -70°C, with good plasticity, similar processability to low-temperature carbon steel | ||

| Nickel steel | 2.25Ni | 450~590 | 255 | 24 | Normalizing | The most economical nickel steel used at -60°C, with better low-temperature toughness than low carbon steel |

| 3.5Ni | 450~690 | 250~440 | 21~29 | Normalizing or tempering | Standard nickel steel used at -100°C, commonly used for low-temperature heat exchange steel pipes | |

| 9Ni | 690~830 | 590 | 21 | Tempering | Nickel steel used at -200°C, with good plasticity and toughness | |

| Carbon-manganese-nickel steel | 15MnNiDR | 460 | 290 | 20 | Normalizing | Steel plates used at -45 to -70°C, with good plasticity and toughness |

| 09MnNiDR | 430 | 260 | 23 | Normalizing or normalizing + tempering | ||

| Carbon-manganese-nickel-chromium-molybdenum steel | 07MnNiCrMoVDR | 610~740 | 490 | 17 | Tempering | Steel plates used at -40°C, with good low-temperature impact toughness |

| High manganese austenitic steel | 15Mn26Al4 | 480 | 200 | 30 | Hot rolled solution | Steel plates used at -253°C, are single-phase Fe-Mn-Al austenitic steel, with good plasticity and toughness |

3. Special performance structural steel

Steel with special physical and chemical properties is called special performance steel. Commonly used special performance steel for sheet metal parts includes stainless steel, heat-resistant steel, and wear-resistant steel.

(1) Stainless steel and heat-resistant steel

GB/T20878—2007 “Stainless Steel and Heat-Resistant Steel Grades and Chemical Composition” lists the grades of stainless steel and heat-resistant steel according to metallurgical classification, divided into austenitic, austenitic-ferritic, ferritic, martensitic, and precipitation hardening types.

Common martensitic stainless steels such as 12Cr13, 20Cr13, and 30Cr13 are mainly used to make medical instruments.

Common austenitic stainless steels such as 06Cr19Ni9 and 12Cr18Ni9 are mainly used to make equipment working in strong corrosive media, such as absorption towers, storage tanks, pipelines, and containers.

Common heat-resistant steels such as 40Cr10Si2Mo and 45Cr14Ni14W2Mo have high oxidation resistance and strength at high temperatures. Among them, the austenitic heat-resistant steel 45Cr14Ni14W2Mo can be used to manufacture parts working below 600°C, such as turbine blades and large engine exhaust valves.

(2) Wear-resistant steel

Wear-resistant steel is mainly used to manufacture parts that withstand severe wear and strong impact, such as vehicle tracks, crusher jaw plates, ball mill liners, excavator buckets, and railway turnouts. Wear-resistant steel has good toughness and wear resistance.

High manganese steel is currently the most important wear-resistant steel, with a carbon content of 0.9% to 1.4% and a manganese content of 11% to 14%. This steel is difficult to machine and is mostly cast. Common high manganese steels include grades such as ZGMn13-1, ZGMn13-2, ZGMn13-3, and ZGMn13-4.

II. Non-ferrous metal materials

Metals other than steel, such as aluminum, magnesium, copper, and lead, and their alloys are collectively referred to as non-ferrous metal materials. In metal materials, non-ferrous metal materials occupy an important position. Among them, aluminum and aluminum alloys, copper and copper alloys, titanium and titanium alloys have characteristics such as low density, high specific strength, heat resistance, corrosion resistance, and electrical conductivity, which are significantly superior to ordinary steel and even surpass some high-strength steels, making them indispensable metal materials in sheet metal.

1. Aluminum and aluminum alloys

Pure aluminum has good electrical and thermal conductivity and high plasticity, and is often used to manufacture conductors and capacitors. However, due to its low strength, it is not suitable for use as a structural material. To improve its strength, alloying elements (such as silicon, copper, magnesium, manganese, etc.) are often added to pure aluminum to form aluminum alloys. These aluminum alloys generally still have special properties such as low density (about 2.5 to 2.88g/cm3), corrosion resistance, and good thermal conductivity.

(1) Aluminum and aluminum alloy grade designation method

Aluminum and aluminum alloys use a four-digit system grade and a four-character system grade for designation. The group and grade series of aluminum and aluminum alloys are shown in Table 7.

Table 7 Group and grade series of aluminum and aluminum alloys

| Group | Grade series |

| Pure aluminum (aluminum content not less than 99.00%) | 1××× |

| Aluminum alloy with copper as the main alloying element | 2××× |

| Aluminum alloy with manganese as the main alloying element | 3××× |

| Aluminum alloy with silicon as the main alloying element | 4××× |

| Aluminum alloy with magnesium as the main alloying element | 5××× |

| Aluminum alloy with magnesium and silicon as the main alloying elements and Mg2Si phase as the strengthening phase | 6××× |

| Aluminum alloy with zinc as the main alloying element | 7××× |

| Aluminum alloy with other alloying elements as the main alloying element | 8××× |

| Reserve alloy group | 9××× |

(2) Comparison of new and old grades of wrought aluminum and aluminum alloys

Due to historical reasons, the grades of wrought aluminum and aluminum alloys are still often used in production. The old grades of aluminum and its alloy products are represented by a combination of code prefixes or element symbols followed by composition numbers or sequence numbers combined with product category or group names, including:

1) Product codes are represented by a combination of Chinese pinyin letters, chemical element symbols, and Arabic numerals, such as aluminum represented by L, hard aluminum by LY, and rust-proof aluminum by LF.

2) Codes for product status, processing methods, and characteristics are represented by Chinese pinyin letters, such as R for hot processing, M for annealed state, T for extra hard, Y for hard, Y1 for 3/4 hard, Y2 for 1/2 hard, Y3 for 1/3 hard, and Y4 for 1/4 hard.

The grades of industrial pure aluminum in China are compiled based on impurity limits, such as L1, L2, L3, etc. L is the initial of the Chinese pinyin for “aluminum,” and the larger the number following it, the lower the purity. High-purity aluminum grades L01 to L04 have an aluminum content of more than 99.93%, and the larger the number following it, the higher the purity, such as L04 with an aluminum content of not less than 99.996%.

Aluminum alloys can be divided into wrought aluminum alloys and cast aluminum alloys based on their composition and process characteristics. Wrought aluminum alloys produced in China are classified into hard aluminum, rust-proof aluminum, super hard aluminum, and forged aluminum based on their main performance characteristics.

Table 8 provides a comparison of new and old grades of wrought aluminum and aluminum alloys.

Table 8 Comparison of new and old grades of wrought aluminum and aluminum alloys

| New grade (GB/T3190—2008) | Old grade |

| 1035 | L4 |

| 1050A | L3 |

| 1060 | L2 |

| 1070A | L1 |

| 1100 | L5-1 |

| 1200 | L5 |

| 5056 | LF5-1 |

| 5083 | LF4 |

| 1A85 | LG1 |

| 1A50 | LB2 |

| 1A30 | L4-1 |

| 2A01 | LY1 |

| 2A02 | LY2 |

| 2A04 | LY4 |

| 2A06 | LY6 |

| 2A10 | LY10 |

| 2A11 | LY11 |

| 2B11 | LY8 |

| 2A12 | LY12 |

| 2B12 | LY9 |

| 2A13 | LY13 |

| 2A14 | LD10 |

| 2A16 | LY16 |

| 2B16 | LY16-1 |

| 2A17 | LY17 |

| 2A20 | LY20 |

| 2A21 | 214 |

| 2A25 | 225 |

| 2A49 | 149 |

| 2A50 | LD5 |

| 2B50 | LD6 |

| 2A70 | LD7 |

| 2B70 | LD7-1 |

| 2A80 | LD8 |

| 2A90 | LD9 |

| 3A21 | LF21 |

| 4A01 | LT1 |

| 4A11 | LD11 |

| 4A13 | LT13 |

| 4A17 | LT17 |

| 6061 | LD30 |

| 6063 | LD31 |

| 6070 | LD2-2 |

| 7003 | LC12 |

| 1A99 | LG5 |

| 1A97 | LG4 |

| 1A93 | LG3 |

| 1A90 | LG2 |

| 4A91 | 491 |

| 5A01 | LF15 |

| 5A02 | LF2 |

| 5A03 | LF3 |

| 5A05 | LF5 |

| 5B05 | LF10 |

| 5A06 | LF6 |

| 5B06 | LF14 |

| 5A12 | LF12 |

| 5A13 | LF13 |

| 5A30 | LF16 |

| 5A33 | LF33 |

| 5A41 | LT41 |

| 5A43 | LF43 |

| 5A66 | LT66 |

| 6A01 | 6N01 |

| 6A02 | LD2 |

| 6B02 | LD2-1 |

| 6A51 | 651 |

| 7A01 | LB1 |

| 7A03 | LC3 |

| 7A04 | LC4 |

| 7A05 | 705 |

| 7B05 | 7N01 |

| 7A09 | LC9 |

| 7A10 | LC10 |

| 7A15 | LC15, 157 |

| 7A19 | LC19, 919 |

| 7A31 | 183-1 |

| 7A33 | LB733 |

| 7A52 | LC52 |

| 8A06 | L6 |

(3) Mechanical properties, main characteristics, and applications of commonly used aluminum and aluminum alloys

Table 9 provides the mechanical properties, main characteristics, and applications of commonly used aluminum and aluminum alloys.

Table 9 Mechanical properties, main characteristics, and applications of commonly used aluminum and aluminum alloys

| Grade | Material state | Shear strength τ//MPa | Tensile strength σb/MPa | Elongation δ10(%) | Yield strength σs/MPa | Main characteristics and applications |

| 1070A(L1), 1050A(L3), 1200(L5) | Annealing | 78 | 74~108 | 25 | 49~78 | It has high corrosion resistance, high plasticity, electrical conductivity, and thermal conductivity, is easy to process under pressure, has good weldability, but low mechanical strength and poor machinability. It is mainly used for non-load-bearing parts and nameplates. |

| Cold work hardening | 98 | 118~147 | 4 | One | ||

| 3A21(LF21) | Annealing | 69~98 | 108~142 | 19 | 49 | It is the most widely used rust-proof aluminum, with low strength and cannot be strengthened by heat treatment, so cold working methods are often used to improve its mechanical properties. It has high plasticity in the annealed state, low plasticity during cold work hardening, good corrosion resistance, good weldability, and poor machinability. It is used for low-load parts working in liquid or gas media. |

| Semi-cold work hardening | 98~137 | 152~196 | 13 | 127 | ||

| 5A02(LF2) | Annealing | 127~158 | 177~225 | 20 | 98 | It has high fatigue strength, plasticity, and corrosion resistance, cannot be strengthened by heat treatment, has good machinability in cold work hardening or semi-cold work hardening state, and poor machinability in annealed state, can be polished. It is used for containers or medium-load parts working in liquid or gas media. |

| Semi-cold work hardening | 158~196 | 225~275 | — | 206 | ||

| 7A04(LC4) | Annealing | 170 | 250 | — | One | Used for main load-bearing structural parts with lightweight requirements, such as aircraft beams, trusses, reinforcement frames, skin joints, and landing gear. |

| Quenching and artificial aging | 350 | 500 | — | 460 | ||

| 2A12(LY12) | Annealing | 103~147 | 147~211 | 12 | 104 | It is a high-strength hard aluminum that can be strengthened by heat treatment. In the annealed and freshly quenched state, it has medium plasticity, good weldability, and moderate corrosion resistance. It is used to make various high-load parts or components. |

| Quenching and natural aging | 275~314 | 392~432 | 15 | 361 | ||

| Cold work hardening after quenching | 275~314 | 392~451 | 10 | 333 |

2. Copper and Copper Alloys

Pure copper can be divided into smelting products and processing products. Smelting products can be divided into No. 1 copper, No. 2 copper, and No. 3 copper based on the mass fraction of impurities. Processing products are divided into pure copper, oxygen-free copper, and phosphorus deoxidized copper based on the mass fraction of oxygen and production methods.

The numbering method for pure copper starts with the Chinese pinyin initial “T” for “copper,” followed by 1, 2, 3, indicating T1, T2, T3. The numbering methods for oxygen-free copper and phosphorus deoxidized copper are “T” + U (the pinyin initial for “no”) + serial number, and “T” + P + serial number, respectively.

Pure copper is a precious metal, with outstanding advantages of excellent electrical conductivity, thermal conductivity, and good corrosion resistance, but low strength and very low hardness, with very good plasticity. It is mainly used as various conductive materials and thermal conductive materials.

To utilize the advantages of pure copper and improve its mechanical properties, alloy elements can be added to pure copper to make copper alloys. These copper alloys generally still have good electrical conductivity, thermal conductivity, corrosion resistance, magnetic resistance, and sufficiently high mechanical properties.

(1) Copper Alloy Grade Representation Method

Copper alloys can be divided into wrought copper alloys and cast copper alloys based on production processes; and into three categories based on chemical composition: brass with Zn as the main additive element, bronze with Sn, Al, Be, Si, Ce, Cr as the main additive elements, and cupronickel with Ni as the main additive element.

Cupronickel is a copper-nickel alloy, mainly used to make corrosion-resistant parts in precision machinery and instruments, as well as resistors and thermocouples. In sheet metal components, brass and bronze are more widely used.

1) Brass (Copper-Zinc Alloy). The grade representation method for brass is as follows:

① The grade of ordinary brass starts with “H” (H is the first letter of the pinyin for “yellow”), followed by the copper content value (in percentage), such as H96, which indicates ordinary brass with a copper mass fraction of about 96%.

② The grade of special brass still starts with “H,” followed by the symbol of the main additive element, and then the copper content value (in percentage), such as HNi65-5, which indicates nickel brass with a copper mass fraction of about 65% and a nickel mass fraction of about 5%.

2) Cupronickel (Copper-Nickel Alloy). The grade representation method for cupronickel is as follows:

① The grade of ordinary cupronickel starts with “B” (B is the first letter of the pinyin for “white”), followed by the nickel content value (in percentage), such as B5, which indicates ordinary cupronickel with a nickel mass fraction of about 5%.

② The grade of special cupronickel still starts with “B,” followed by the symbol of the main additive element, and then the nickel content value (in percentage), such as BFe10-1-1, which indicates iron cupronickel with a nickel mass fraction of about 10%.

3) Bronze. All other copper alloys except brass and cupronickel are called bronze. To distinguish them, the element name is prefixed to bronze, such as tin bronze, aluminum bronze, beryllium bronze, manganese bronze, silicon bronze, etc.

The grade representation method for bronze is as follows: it starts with “Q” (Q is the first letter of the pinyin for “green”), followed by the symbol of the main additive element, and then the content value of the main additive element (mass fraction), such as QSn1.5-2, which indicates tin bronze with a tin mass fraction of about 1.5%.

(2) Mechanical Properties, Main Characteristics, and Applications of Common Copper and Copper Alloys

Table 10 provides the mechanical properties, main characteristics, and applications of common copper and copper alloys.

Table 10 Mechanical Properties, Main Characteristics, and Applications of Common Copper and Copper Alloys

| Material Name | Grade | Material State | Shear Strength τ/MPa | Tensile Strength σb/MPa | Elongation δ10(%) | Yield Strength σs/MPa | Main Characteristics and Applications |

| Pure Copper | T1, T2, T3 | Soft | 157 | 196 | 30 | 69 | It has high electrical conductivity, thermal conductivity, corrosion resistance, and good ductility and machinability, but low mechanical properties, and cannot be used as structural parts. It is mainly used to manufacture oil pipes, sealing gaskets, rivets, and conductive parts. |

| Hard | 235 | 294 | 3 | — | |||

| Brass | H62 | Soft | 255 | 294 | 35 | — | It has good mechanical properties, better plasticity in the hot state than in the cold state, good machinability, easy brazing and welding, corrosion resistance, but prone to stress corrosion cracking. It is cheap and widely used. Mainly used to manufacture various deep-drawn parts and load-bearing parts made by bending, such as screws, nuts, radiators, etc. |

| Semi-hard | 294 | 373 | 20 | 196 | |||

| Hard | 412 | 412 | 10 | — | |||

| H68 | Soft | 235 | 294 | 40 | 98 | It has good plasticity, high strength, good machinability, easy welding, can withstand general corrosion, but prone to stress corrosion cracking. Mainly used to manufacture various complex deep-drawn parts and thermal conductive parts, such as pipes, bellows, gaskets, etc. | |

| Semi-hard | 275 | 343 | 25 | — | |||

| Hard | 392 | 392 | 15 | 245 | |||

| Lead Brass | HPb59-1 | Soft | 300 | 350 | 25 | 145 | It has good machinability, good mechanical properties, can withstand hot and cold pressure processing, easy brazing and welding, good stability against general corrosion, but has a tendency to stress corrosion cracking. Suitable for making various structural parts by hot stamping and machining, such as screws, washers, gaskets, bushings, nuts, etc. |

| Hard | 400 | 450 | 5 | 420 | |||

| Manganese Brass | HMn58-2 | Soft | 340 | 390 | 25 | 170 | Good corrosion resistance. Suitable for manufacturing instrument parts, shock absorber parts, and also suitable for manufacturing high-strength brazed parts. |

| Semi-hard | 400 | 450 | 15 | — | |||

| Hard | 520 | 600 | 5 | — | |||

| Tin Phosphor Bronze, Tin Zinc Bronze | QSn6.5-0.4 QSn4-3 | Soft | 255 | 294 | 38 | 137 | It has high wear resistance and elasticity, good magnetic resistance. Mainly used to manufacture springs and their elastic elements, wear-resistant parts, etc. |

| Hard | 471 | 539 | 3~5 | — | |||

| Extra Hard | 490 | 637 | 1~2 | 535 | |||

| Aluminum Bronze | QAl7 | Annealing | 520 | 600 | 101 | 186 | Pressure processing in the cold state. Resistant to light friction, good corrosion resistance, and certain resistance to sulfuric acid and acetic acid. Suitable for manufacturing parts working in seawater, chemical parts, movable contacts, etc. |

| Not Annealed | 560 | 650 | 5 | 250 | |||

| Aluminum Manganese Bronze | QAl9-2 | Soft | 360 | 450 | 18 | 300 | It has high strength, very good corrosion resistance in the atmosphere and seawater, can be electric welded and gas welded, not easy to braze, good pressure processability in both hot and cold states. Mainly used to manufacture high-strength corrosion-resistant parts and pipe fittings working in steam media below 250°C and parts on sea vessels. |

| Hard | 480 | 600 | 5 | 500 | |||

| Silicon manganese bronze | QSi3-1 | Soft | 280~300 | 350~380 | 40~45 | 239 | It has high strength and elasticity, good wear resistance, good plasticity, and does not decrease at low temperatures. It is easy to braze and weld, does not produce sparks when struck, has good corrosion resistance, but poor heat treatment effect. It is usually used in the cold work hardened state. Used to manufacture springs, elastic elements, parts working in corrosive media, as well as worm wheels, gears, bushings, etc. |

| Hard | 480~520 | 600~650 | 3~5 | 540 | |||

| Extra hard | 560~600 | 700~750 | 1~2 | — | |||

| Beryllium bronze | QBe2 | Soft | 240~480 | 300~600 | 30 | 250~350 | It has very high strength, elasticity, yield limit, and fatigue limit, as well as high conductivity, thermal conductivity, wear resistance, and hardness. It is non-magnetic, does not spark when struck, and is easy to weld and braze. It has good corrosion resistance in the atmosphere and seawater. Used to manufacture various precision instruments, springs and elastic elements in instruments, various wear-resistant parts, and bearings and bushings working under high temperature, high pressure, and high speed. |

| Hard | 520 | 660 | 2 | — |

3. Titanium and titanium alloys

Titanium materials can be divided into chemically pure titanium (iodine titanium), industrial pure titanium, and titanium alloys based on their composition mass fraction. Chemically pure titanium is high-purity titanium, represented by TAD, with a purity of up to 99.95% and a small mass fraction of impurities. Industrial pure titanium has a slightly larger mass fraction of impurities and can be divided into nine grades based on impurity content, with grades represented by TA1, TA2, TA3, etc., with purity decreasing as the sequence number increases.

The yield strength and tensile strength of industrial pure titanium at room temperature are close, with a large yield ratio and low elastic modulus. However, as the temperature increases, the strength decreases to about half of that at room temperature. Conversely, as the temperature decreases, the strength increases, but the plasticity decreases significantly. For high-purity industrial pure titanium, there is no low-temperature transition brittleness, and the impact toughness increases at low temperatures. Therefore, TA1 and TAD can be safely used at -196°C.

To improve certain properties of pure titanium, alloy elements are often added to pure titanium for strengthening, forming titanium alloys. The main alloy elements added include Al, Sn, V, Cr, Mo, Fe, Si, etc. The addition of alloy elements can improve the strength, heat resistance, and corrosion resistance of titanium alloys to a certain extent.

Titanium alloys are divided into deformed (processed) titanium alloys and cast titanium alloys based on the forming method, and into structural titanium alloys (working temperature below 400°C), heat-resistant titanium alloys (working temperature above 400°C), and corrosion-resistant titanium alloys based on usage characteristics.

(1) Titanium and titanium alloy grade designation method

The grade of titanium and titanium alloys is composed of the letter “T” + a letter representing the type of metal or alloy element structure (A, B, C) and a sequence number, with “ELI” indicating extra low interstitial. A represents α-type titanium and α-type titanium alloys, B represents β-type titanium alloys, and C represents α+β-type titanium alloys. Different structural states of various titanium and titanium alloys have different characteristics.

(2) Mechanical properties, main characteristics, and applications of commonly used titanium and titanium alloys

Table 11 shows the mechanical properties, main characteristics, and applications of commonly used titanium and titanium alloys.

Table 11 Mechanical properties, main characteristics, and applications of commonly used titanium and titanium alloys

| Material name | Grade | Material state | Shear strength τ/MPa | Tensile strength σb/MPa | Elongation δ10(%) | Yield strength σs/MPa | Main characteristics and applications |

| Titanium alloy | TA1 | Annealed | 360~480 | 450~600 | 25~30 | — One | Low density, high specific strength, good high and low temperature performance, excellent corrosion resistance, mainly used for manufacturing aerospace industry structural parts, such as bolts, rivets, sheet metal parts, etc. |

| TA2 | 440~600 | 550~750 | 20~25 | — | |||

| TB5 | 640~680 | 800~850 | 15 | — |

Note: The first two digits of the grade indicate the code for the type of titanium or titanium alloy structure, and the third digit indicates the sequence number of the titanium or titanium alloy.