Sheet metal parts utilize material as one of the three significant elements of sheet metal production. With advanced sheet metal process and mold technology, only by adopting material with good stamping performance can high-quality sheet metal parts be manufactured. The selection and comprehensive properties of materials have a crucial impact on the cost, performance, quality, and processability of the product.

Sheet materials refer to semi-finished products of various shapes, like thin plates, medium plates, thick plates, narrow strips, and strip materials.

Classified by thickness, they include thick plates (above 4mm), medium plates (3~4mm), and thin plates (below 3mm).

Sheet materials, depending on their rolling state, are categorized into hot-rolled and cold-rolled steel plates.

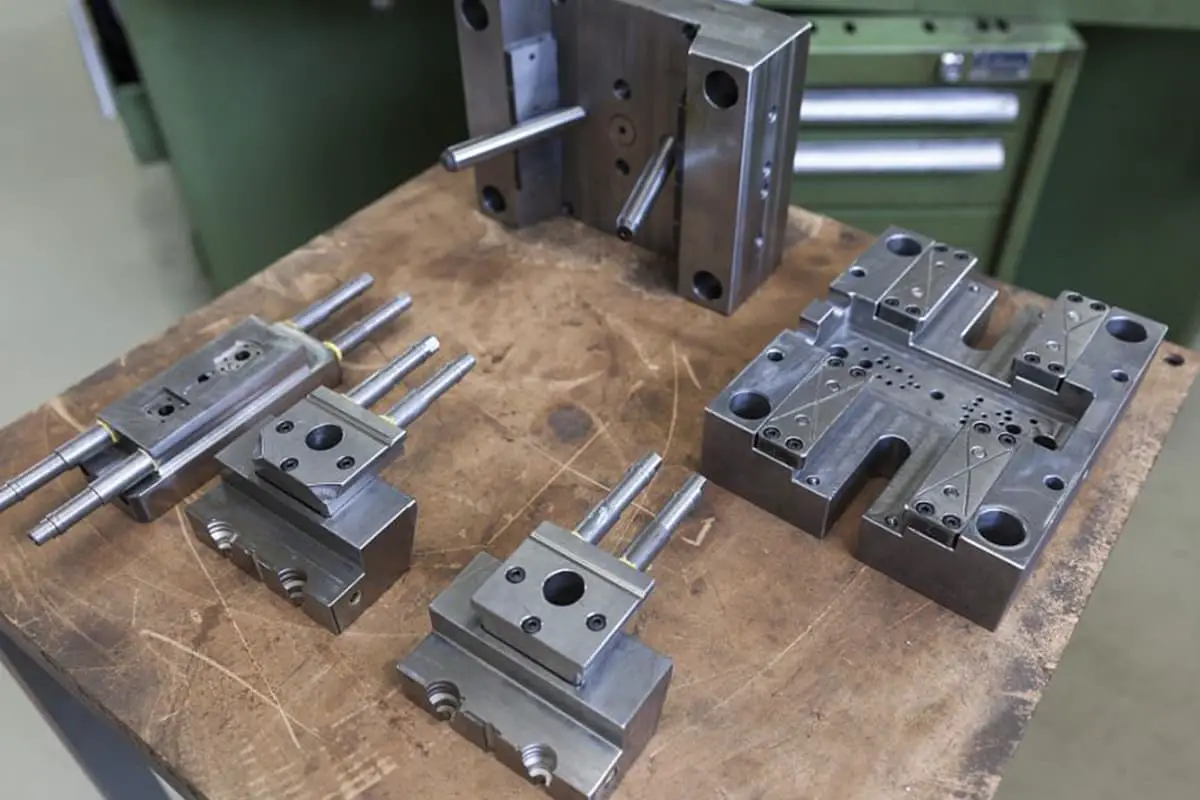

I. Material Selection for Sheet Metal

1) Common metal materials should be prioritized and kept within the range of the company’s material handbook.

2) Within the same product, try to minimize the variety of materials and specifications of plate thickness and dimensions.

3) While ensuring the part’s functionality, use cost-effective materials to reduce material costs.

4) Along with ensuring the part’s functionality, consider the stamping performance and requirements of the material and the stamping process to guarantee the rationality and quality of part processing.

II. Introduction to Common Metal Materials

1. Steel Plate

(1) Cold-Rolled Thin Steel Plate

The cold-rolled thin steel plate is a term for the cold-rolled steel plate of carbon structural steel. It is made by further cold-rolling a hot-rolled steel strip of carbon structural steel, producing a steel plate less than 4mm thick, commonly known as a cold plate.

As it is rolled at room temperature, no iron oxide forms, resulting in excellent surface quality, high dimensional accuracy, and superior mechanical and process performance than hot-rolled thin steel plates, thanks to annealing. Cold-rolled thin steel plates are further divided into cold-rolled ordinary thin steel plates and cold-rolled high-quality thin steel plates.

1) The cold-rolled ordinary thin steel plate is a term for the cold-rolled steel plate of ordinary carbon structural steel. It is made by further cold-rolling a hot-rolled steel strip of ordinary carbon structural steel, producing a steel plate less than 4mm thick. It is widely used in many fields, particularly in household appliances, specialized radio equipment, and in the cases and cabinets of power electronics, gradually replacing hot-rolled thin steel plates.

①The applicable models of cold-rolled ordinary thin steel plates include: Q195, Q215, Q235, Q275.

2) Like the cold-rolled ordinary thin steel plate, the cold-rolled high-quality thin steel plate is also the most widely used thin steel plate in cold plates.

The cold-rolled high-quality carbon thin steel plate is made of high-quality carbon structural steel, cold-rolled into a thin plate less than 4mm thick.

①The applicable models of cold-rolled high-quality thin steel plates include: 08, 8F, 10, 10F.

The price of cold-rolled thin steel sheets exceeds that of regular thin steel sheets and is slightly less than that of galvanized steel sheets. Its surface is flat and smooth, but it’s prone to rust when exposed to dampness, necessitating timely painting for protection to extend its lifespan.

(2) Cold-rolled thin steel sheets for deep drawing

Deep-drawing cold-rolled thin steel sheets usually employ aluminum deoxidized calm steel, a type of high-quality carbon structural steel. Because of its superior plasticity and excellent deep drawability, it’s extensively used in products that require deep-drawing of complex structures.

(3) Japanese cold-rolled carbon thin steel sheets

Applicable grades for Japanese cold-rolled carbon thin steel sheets include SPCC, SPCD, and SPCE.

(4) German cold-rolled carbon thin steel sheets

Applicable grades for German cold-rolled carbon thin steel sheets include St12, St13, St14, St15, and St14-T.

(5) Continuous galvanized cold-rolled thin steel sheets

Also known as “electrolytic plates,” these refer to the sheets where zinc is continuously deposited from an aqueous solution of zinc salt onto the surface of pre-prepared cold-rolled thin steel sheets (strips) under the influence of an electric field on the galvanizing line. This results in a uniform, dense, and well-bonded surface layer of zinc.

Due to process limitations, this layer is relatively thin. Zinc, being a relatively inexpensive and easily coated metal, is widely used to protect steel parts, particularly against atmospheric corrosion, and for decorative purposes. Coating techniques include dip coating (or hanging), roll feeding (suitable for small parts), automatic coating, and continuous coating (suitable for wires and strips).

Electrolytic plates are rolled by a cold continuous rolling mill group, then annealed by a CAPL (cold-rolled annealing pickling line) unit, and finally enter the galvanizing unit. After surface cleaning and electroplating, they undergo various treatments such as phosphating, passivation, oiling, and fingerprint resistance, and alloying, depending on their intended use. The mechanical properties of these plates refer to the corresponding base plate.

Applicable grades for electrolytic plates include DX1, DX2, DX3, and DX4.

(6) Japanese Electro-Galvanized Thin Steel Sheet

1) Applicable grades for Japanese Electro-Galvanized Thin Steel Sheet: SECC (original plate SPCC), SECD (original plate SPCD), SECE (original plate SPCE).

2) Zinc layer codes: F8, E16, E24, E32.

(7) Comparison between domestic and foreign product grades of Continuous Electro-Galvanized Cold Rolled Thin Steel Sheet, see Table 1-1.

Table 1-1 Comparison of domestic and foreign product grades of Continuous Electro-Galvanized Cold Rolled Thin Steel Sheet.

| Baosteel Q/B QB 430-2009 | Japan JISG3313:1998 | National Standard GB/T15675-2008 | United States ASTMA591A591M-98(Circuit Board) |

| SECC | SECC | DX1 | CS |

| SECD | SECD | DX2 | DS |

| SECE | SECE | DX3 | DDS |

| SECIF | – | – | EDDS |

(8) Continuous Hot-Dip Galvanized Thin Steel Sheet

This is often referred to as galvanized sheet or tinplate, referring to cold-rolled continuous hot-dip galvanized thin steel sheets and strips with a thickness of 0.25~2.5mm. The steel strip first passes through a preheating furnace heated by a flame to burn off surface residual oil, while generating an iron oxide film on the surface.

It is then heated to 710~920 degrees Celsius in a reduction annealing furnace with a mixed gas of hydrogen and nitrogen to reduce the iron oxide film into sponge iron. The activated and purified steel strip is cooled to a temperature slightly higher than the melting point of zinc, then enters a zinc pot at 450~460 degrees Celsius.

The zinc layer surface thickness is controlled using an air knife. Finally, it undergoes passivation with a chromate solution to increase white rust resistance. The surface of the continuous hot-dip galvanized thin steel sheet is aesthetically pleasing, with block or leaf-like zinc crystal patterns. The coating is sturdy, with excellent atmospheric corrosion resistance.

Moreover, the continuous hot-dip galvanized thin steel sheet also has good weldability and cold forming properties. Compared to the surface of the continuous electro-galvanized cold-rolled thin steel sheet, its coating is thicker and is mainly used for sheet metal parts that require strong corrosion resistance.

1) Applicable grades for continuous hot-dip galvanized thin steel sheet: Zn100-PT, Zn200-SC, Zn275-JY.

(9) Japanese Hot-Dip Galvanized Thin Steel Sheet

1) Applicable grades for Japanese Hot-Dip Galvanized Thin Steel Sheet: SGCC, SGCD1, SGCD2, SGCD3.

(10) German Hot-Dip Galvanized Thin Steel Sheet

1) Applicable grades for German Hot-Dip Galvanized Thin Steel Sheet: St01Z, St02Z, St03Z, St04Z, St05Z.

2) Zinc layer codes: 100, 180, 200, 275, 350, 450.

(11) Aluminum-Zinc Coated Sheet

Also known as aluzinc steel sheet, this material’s alloy layer consists of 55% aluminum, 43.4% zinc, and 1.6% silicon, solidified at a high temperature of 600 degrees Celsius. Its entire structure forms a compact quaternary crystal layer of aluminum-iron-silicon-zinc, offering excellent corrosion resistance.

With regular use, its lifespan can reach 25 years, 3 to 6 times longer than galvanized sheets, and comparable to stainless steel sheets.

1) The corrosion resistance of the aluminum-zinc coated sheet comes from the protective functions of the aluminum barrier layer and the sacrificial protection of zinc. When zinc offers sacrificial protection at the sheet edges, scratches, and damaged coating areas, aluminum forms an insoluble oxide layer, providing barrier protection.

Aluzinc alloy steel coils have undergone over 20 years of outdoor exposure tests in various atmospheric conditions, confirming that aluzinc steel sheets with 55% aluminum coating offer better edge protection than those with 5% aluminum coating.

2) Aluminum-zinc coated sheets have better heat resistance than galvanized steel sheets, similar to the high-temperature oxidation resistance of aluminized steel sheets, and can be used in environments up to 315 degrees Celsius.

3) The high reflectivity of aluminum-zinc coated sheets makes them effective heat barriers. Their heat reflectance is nearly double that of galvanized steel sheets, thus, they can serve as roofing and siding for energy-saving effects, even without painting.

4) Due to the excellent adhesion between the zinc layer of the aluminum-zinc coated sheet and the paint, it can be painted for general purposes without pretreatment and weathering, while galvanized steel sheets require weathering and pretreatment.

(12) Cold-Rolled Stainless Steel Sheet

Because of its strong corrosion resistance, good conductivity, and high strength, this material is widely used in industries such as chemicals, food, medicine, paper, oil, nuclear energy, as well as in construction, kitchenware, tableware, vehicles, household appliances, and various parts.

However, its drawbacks also need to be fully considered: the material cost is four times that of ordinary galvanized sheets; the material’s high strength causes significant wear on the tooling of press machines, making it generally unsuitable for processing on CNC press machines; the pressure rivet nuts used for stainless steel sheets must be made from high-strength special stainless steel material, which is expensive, and the riveting is not sturdy, often requiring additional spot welding for reinforcement;

The adhesion of surface coating is not high, and quality control is challenging; due to the material’s significant springback, it’s challenging to ensure shape and dimensional accuracy during bending and stamping.

1) Suitable grades for cold-rolled stainless steel sheet: 20Cr13, 10Cr17.

2) Common stainless steel grades, types, and uses are shown in Table 1-4.

Table 1-4 Common Stainless Steel Grades, Types, and Uses

| Grade | Type | Applications |

| 1Cr18Ni9Ti① | Austenitic | Manufacture of welding cores, anti-magnetic instruments, medical apparatus, acid-resistant containers, and lining for conveyance pipelines among other equipment and parts. |

| 06Cr25Ni20 | Austenitic | Materials for furnaces and automotive exhaust purification devices. |

| 12Cr18Ni9 | Austenitic | Exhibits high strength after cold working, suitable for architectural decorative components. |

| 06Cr19Ni10 | Austenitic | As the most widely used stainless heat-resistant steel, it is employed in food equipment, general chemical equipment, and nuclear industry. |

| 022Cr19Ni10 | Austenitic | Used in sectors requiring high intergranular corrosion resistance, such as the chemical, coal, and petroleum industries. Suitable for outdoor machinery, building materials, heat-resistant parts, and hard-to-heat-treat components exposed to the elements. |

| 06Cr17Ni12Mo2 | Austenitic | Appropriate for seawater and other media, primarily used as pitting corrosion-resistant material. Used in photography, the food industry, coastal area facilities, ropes, CD rods, bolts, and nuts. |

| 022Cr17Ni12Mo2 | Austenitic | Super low carbon steel version of 06Cr17Ni12Mo2, used for products with special requirements against intergranular corrosion. |

| 1Cr18Ni12Mo2Ti | Austenitic | This equipment, suited for resisting sulfuric acid, phosphoric acid, formic acid, and acetic acid, demonstrates excellent intergranular corrosion resistance. |

| 08Cr17Ni12Mo2Ti | Austenitic | The same applies here. |

| 06Cr18Ni11Ti | Austenitic | The addition of titanium enhances intergranular corrosion resistance. However, it’s not recommended for decorative components. |

| OCr16Ni14 | Austenitic | Non-magnetic stainless steel is primarily used for non-magnetic metal parts within electron tubes. |

| 16Cr20Ni14Si2 | Austenitic | This material possesses high-temperature strength and oxidation resistance. It is sensitive to sulfur and nitrogen gases and tends to become brittle due to phase precipitation between 600 to 800 degrees Celsius. It is suitable for creating various furnace components that bear stress. |

| 12Cr17Ni7 | Austenitic | This metal is suitable for high-strength components and materials used in train and bus cabins. |

| 022Cr19Ni5Mo3Si2N | Austenitic + Ferritic | With good resistance to stress corrosion cracking and high strength, this material is suitable for environments containing oxygen ions. It is used in the oil refining, fertilizer, papermaking, petroleum, and chemical industries for the manufacture of heat exchangers and condensers. |

| 022Cr12Ti | Ferritic | It is used for automobile muffler pipes and decorative applications. |

| 06Cr13 AI | Ferritic | This material doesn’t harden significantly when cooled at high temperatures. It’s used for turbine materials, quenching components, and composite steel materials. |

| 10Cr17 | Ferritic | This is a general-purpose, corrosion-resistant steel used for indoor decorations, heavy-duty diesel combustion components, household utensils, and home appliance parts. |

| 06Cr13 | Martensitic | This material is used for creating parts that require high toughness and impact load, such as turbine blades, structural frames, bolts, and nuts. |

| 12Cr13 | Martensitic | With excellent corrosion resistance and machinability, it is used for general purposes, knife blades, mechanical parts, petroleum refining equipment, bolts, nuts, pump rods, cutlery, and so forth. |

| 20Cr13 | Martensitic | In the hardened state, it possesses high hardness and good corrosion resistance, making it ideal for applications such as turbine blades and cutlery, including knives. |

①The 1Cr18Ni9Ti grade was abolished in GB/T 20878-2007.

2. Aluminum and Aluminum Alloy Plates

The commonly used aluminum and aluminum alloy plates primarily include the following materials: 3A21, 5A02, hard aluminum 2A12, and hard aluminum 2A06.

1) Anti-rust aluminum 3A21 (old grade LF21, Al-Mn alloy) is the most widely used anti-rust aluminum. This alloy’s strength isn’t high (just higher than industrial grade), can’t be strengthened by heat treatment, and typically employs cold processing methods to enhance its mechanical properties. It has high plasticity in an annealed state and decent plasticity in semi-cold work hardening.

The plasticity is low during cold work hardening, yet it possesses good corrosion resistance, weldability, and poor machinability. It is fit for manufacturing parts requiring high plasticity and good weldability, working in liquid or gaseous media under low load.

2) Anti-rust aluminum 5A02 (old grade LF2, Al-Mg alloy) has better strength than 3A21, particularly a higher fatigue strength, plasticity, and corrosion resistance. It can’t be strengthened by heat treatment and has good weldability with contact welding and hydrogen welding.

However, it tends to form crystalline cracks during arc welding. The alloy can be machined well in the cold work hardening and semi-cold work hardening state, while its machinability is poor in the annealed state. It can be polished.

3) Hard aluminum 2A12 (old grade LY12) is the most widely used high-strength hard aluminum, used for manufacturing high-load parts and structural components operating below 150 degrees Celsius. It can be heat-treated to increase strength. It has medium plasticity in the annealed and freshly quenched state, and decent cutting performance after quenching and cold work hardening.

After annealing, its machinability is low. Spot welding is good, but it tends to form intergranular cracks during gas welding and argon arc welding. Its corrosion resistance isn’t high, typically improved by anodizing, painting, or coating with aluminum. Its plasticity is poor, and bending in the normal state can cause cracking at the outer rounded corners. The plate can be bent within about 1-3 hours from annealing and just-quenched state to hardening.

4) Hard aluminum 2A06 (old grade LY6) is a commonly used hard aluminum. Its pressure processing performance and machinability are the same as 2A12. It has decent plasticity in the annealed and freshly quenched state. 2A06 can be quenched and aged, and its general corrosion stability is the same as 2A12.

When heated to 150-250 degrees Celsius, it has a smaller tendency to form intergranular corrosion than 2A12. Its spot welding is the same as 2A12 and 2A16, and its arc welding is better than 2A12 but worse than 2A16. It can serve as a material for some panel types, but its plasticity is poor. Bending in the normal state can cause cracking at the outer rounded corners. The plate can be bent within about 1-3 hours from annealing and just-quenched state to hardening.

3. Copper and Copper Alloy Sheets

There are primarily two kinds of commonly used copper and copper alloy sheets: Pure Copper (T2) and Brass (H62).

1) Pure Copper (T2) is the most frequently used, appearing purple in color. It possesses high electrical and thermal conductivity, along with excellent corrosion resistance and formability. However, it is much less strong and hard compared to brass, and it is quite expensive. It is mainly used for conductive, heat-resistant, and anti-corrosive equipment, typically for components that need to carry large currents in power supplies.

2) Brass (H62) belongs to the high-zinc brass category. It offers superior strength and excellent cold and hot workability, easily undergoing various forms of pressure processing and cutting. It is primarily used for various deep-drawn and bent load-bearing components. While its electrical conductivity is not as good as pure copper, it boasts good strength and hardness, and its price is reasonably moderate.

When the requirement for conductivity is met, choosing Brass H62 over pure copper can significantly reduce material costs. Currently, most of the bus bars’ conductive pieces are made of Brass H62, which has been proven to fully meet the requirements.