Key takeaways:

- CNC machine manufacturers are pivotal in driving innovation and efficiency in manufacturing, with top companies like Mazak, Okuma, Makino, MAG, and SMTCL leading the way by offering advanced technologies such as IoT and AI, custom solutions, and comprehensive global support to address industry challenges like labor shortages and the need for sustainable development.

- The leading brands in the CNC industry not only provide high-quality machinery but also contribute to the broader manufacturing landscape through a commitment to environmental sustainability, customer-tailored engineering, and the integration of control devices and machine tools, which are essential for industries requiring high precision such as automotive and medical device manufacturing.

- Japanese CNC manufacturers dominate the market with a rich history and global presence, emphasizing their innovative approaches—such as Okuma’s “heat-friendly concept” and Mazak’s global production system—while American and Chinese companies like MAG and SMTCL offer competitive processing solutions and turnkey systems, illustrating a diverse and technologically advanced industry landscape.

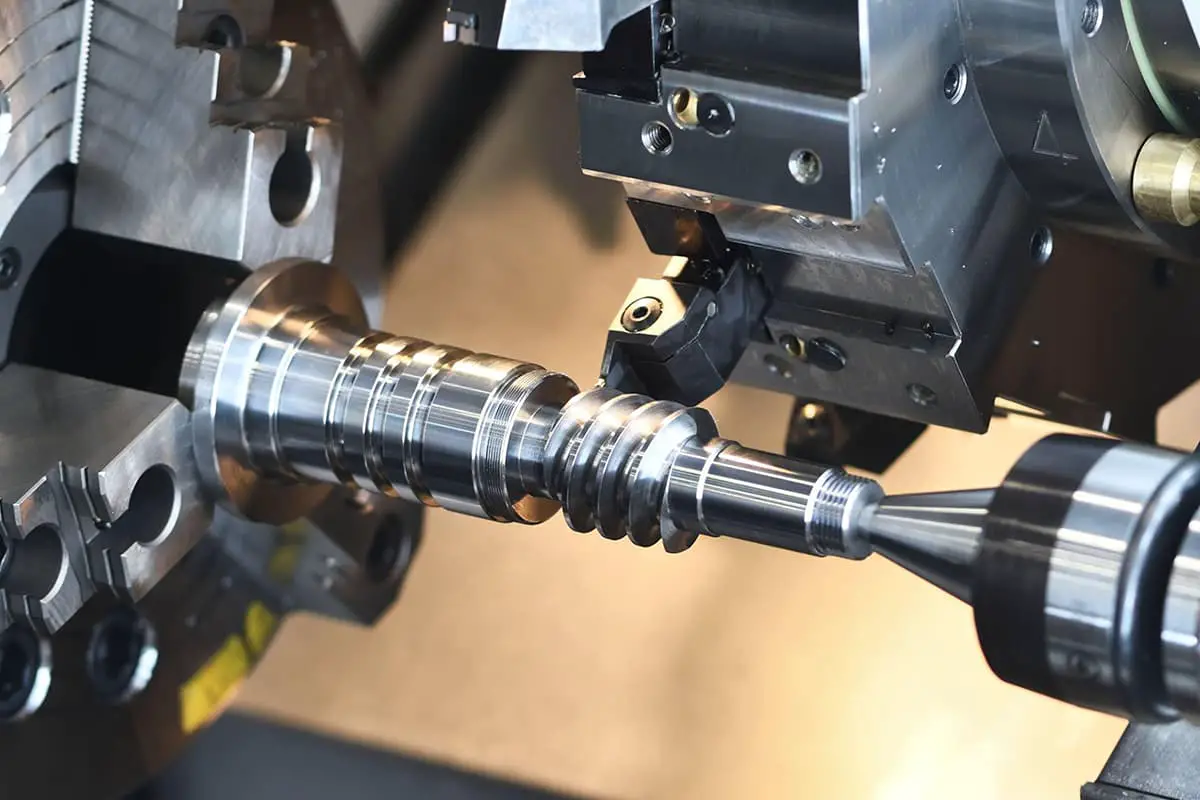

Computer Numerical Control (CNC) machines represent the pinnacle of manufacturing precision, automation, and efficiency. These sophisticated devices control machining tools such as lathes, mills, routers, and grinders through the use of computer programming, ensuring high precision and consistency across production runs. The landscape of CNC machine manufacturers is diverse, with various brands leading the charge in innovation and quality across different sectors.

Amongst the top CNC machine manufacturers, certain names frequently surface due to their reliability, technological advancements, and comprehensive customer support. Brands like FANUC are noted for their integration of CNC with robotic automation, particularly benefiting the automotive industry with streamlined production processes. Similarly, Haas has made a mark in both domestic and international markets, offering a variety of CNC equipment suitable for various applications, including medical device manufacturing, where precision is critical. The best CNC manufacturers not only supply superior machinery but also contribute to advancements in production capabilities for a multitude of industries.

Leading CNC Machine Manufacturers

1. Mazak

Country: Japan

Founded: 1919

About the company:

Yamazaki Mazak is an enterprise in the Japanese machine tool industry that started overseas production earlier.

Since the establishment of the American factory in 1974, many production bases have been established in Britain, Singapore and China.

It is one of the few machine tool manufacturers that has established a global production system.

Since its establishment, Mazak has promoted globalization by actively expanding production and support bases, and continued to make contributions to customer development and manufacturing industry around the world by providing high-quality products and technologies.

It is Mazak’s mission as a machine tool manufacturer to contribute to the society and make people’s lives more colorful.

At present, the manufacturing industry is facing various problems such as labor shortage.

Mazak will use advanced technologies such as loT and AI to accelerate the development of new products and services, and provide customers with solutions to promote automation and more intelligent production sites.

Yamazaki Mazak (China) Co., Ltd. is a wholly-owned subsidiary of Yamazaki Mazak Co., Ltd. in China.

Fully responsible for Mazak’s R&D, production, sales and services in the Chinese market.

Through long-term investment, a comprehensive customer support system covering production, sales, engineering technology, after-sales service and spare parts support has been established, mainly including a comprehensive after-sales service facility integrating spare parts, training and service – Yamazaki Mazak China Spare Parts Center;

Two advanced intelligent network chemical plants – Ningxia Xiaobairen Machine Tool Co., Ltd. (2000) and Yamazaki Mazak Machine Tool (Liaoning) Co., Ltd. (2013); Shanghai (2008), Guangzhou and Dalian (2010) three technical centers integrating exhibition, spare parts, training and technical support;

4 technical service centers in Beijing, Chongqing, Suzhou and Hangzhou and sales outlets all over the country.

2. Okuma

Country: Japan

Founded: 1918

About the company:

Okuma Co., Ltd., one of the largest CNC machine tool factories in Japan, has a history of more than 100 years.

It mainly produces general CNC lathes and machining centers, and develops and produces OSP CNC devices by itself.

Its products are famous for their good rigidity, high efficiency, stable accuracy, long life and convenient operation.

The main overseas strongholds include Okuma America, Okuma Europe, Okuma Singapore Branch, Datong Daisuke Co., Ltd. (Taiwan), Daisuke Technology (Thailand), Okuma Australia, Okuma Machine Tool (Shanghai) Co., Ltd., Beiyi Okuma (Beijing) Machine Tool Co., Ltd., Korean Technical Service Center, and Okuma India.

Japan Okuma Co., Ltd. started its business in January 1898 and was founded in July 1918.

The company is headquartered in Okuchi, Danyu Prefecture, Aichi Prefecture, Japan, with Yamato as the general manager, 2908 employees (April 2009) (consolidated) and a capital of 18 billion yen.

The theory of “heat affinity concept” with precision beyond people’s imagination, and the reassuring “machine tool without impact” developed by Okuma Co., Ltd. are also the symbols of innovation spirit of Okuma.

As a supplier of “integration of machine tools and control devices” for customers, Okuma’s commitment to the future is to manufacture higher quality products and provide better services to meet the needs of more and more customers around the world.

At the same time, Okuma also sincerely hopes that more people around the world can understand and agree with what Okuma knows and feels: product manufacturing reflects the art of manufacturing and the joy of manufacturers.

Compared with ordinary consumer goods, machine tools of Japan Okuma Co., Ltd. have a longer service life and can be recycled as steel resources when discarded. In order to make its products always face the society of sustainable development, Okuma Company focuses on reducing the environmental load and improving the quality of products and services that achieve high productivity.

3. Makino

Country: Japan

Founded: 1930

About the company:

In 1930, Tsunezo Makino established his first machining workshop in Tokyo, Japan.

Nearly a century later, Tokyo is still the global headquarters of Seino Milling Machine Co., Ltd.

Through the Tokyo headquarters, Makino sells mechanical equipment, tools and solutions to Japan, Chinese Mainland, South Korea and Taiwan, China.

Makino’s research and development department in Tokyo launched a commercial horizontal processing center.

As an industry leader in the development and innovation of mechanical equipment and systems, Makino has always been committed to meeting future challenges.

Today, wild products have been sold to 41 countries or regions around the world.

As an industry leader in mechanical design and digital innovation, Makino has launched a Loyalty solution with excellent performance.

Makino produces metal cutting and EDM machines with high precision and quality all over the world, including horizontal machining centers, vertical machining centers, five axis machining centers, graphite machining centers, wire EDM machines and EDM forming machines.

4. Mag

Country: USA

Founded: 1798

About the company:

MAG, one of the professional suppliers of processing solutions, mainly provides users with customized machine tools and turnkey manufacturing systems.

MAG has integrated international famous brands in the machine tool industry, Cross Huller, Ex-Cel-O and Lamb.

Since 2005, MAG has been active in the global manufacturing industry with its unique technical know-how and excellent technical foundation, and has become a trusted manufacturing expert worldwide.

MAG Group provides high-quality, efficient and effective solutions for the automotive and commercial vehicle industry and its suppliers as well as other industries.

Especially in the automotive industry, MAG provides high-precision workpieces to ensure that the functionality of the workpieces can be brought into play.

For example, the service life of the piston can be significantly extended through precision machining and honing process for cylinder hole processing.

As an industrial equipment supplier, MAG provides you with a full range of solutions, from processing technology, process design to manufacturing system configuration planning to the turnkey of the entire manufacturing system.

5. SMTCL

Country: China

Founded: 1933

About the company:

Shenyang Machine Tool Co., Ltd. is a joint-stock enterprise jointly initiated by Shenyang No. 1 Machine Tool Factory, Zoje Friendship Factory, Shenyang No. 3 Machine Tool Factory and Liaoning Precision Instrument Factory.

It was established in May 1993 and approved by the Shenyang Economic System Reform Commission in document No. 199231.

In July 1996, with the approval of ZJFSZ No. 1996112 issued by China Securities Regulatory Commission, the company publicly issued 54 million yuan of common shares to the public.

After the issuance, the total capital stock of the company was 215823518 yuan, and the company was listed on the Shenzhen Stock Exchange with the stock code of 00410.

The company is a subsidiary of Shenyang Machine Tool (Group) Co., Ltd.

Since 2010, Shenyang Machine Tool Co., Ltd. has insisted on using new technologies and materials to improve product quality.

Its CNC turret branch successfully replaced ZQSn6-6-3 copper alloy with microcrystalline alloy LZA4205 worm gear special material, which further improved the quality of CNC turret products of Shenyang Machine Tool Co., Ltd., and at the same time, controlled the cost, greatly improving the competitiveness of Shenyang Machine Tool Co., Ltd.

At present, Shenyang CNC Machine Tool Industrial Park has been relocated and has achieved professional restructuring.

There are nine complete machine enterprises, including Shenyang First Machine Tool Factory, Zoje Machine Tool Co., Ltd., Shenyi Lathe Factory, Zoje Drilling Lithium Machine Factory, Shenyi Heath CNC Machine Tool Business Unit, Zoje Vertical Machining Center Business Unit, Complete Equipment Co., Ltd., Laser Technology Business Unit and FIDIC CNC Machine Tool Co., Ltd.

Through professional restructuring, business process reengineering and information construction, Shenyang CNC Machine Tool Industrial Park will become a modern (single) CNC machine tool manufacturing base with a proud global scale.

6. DMTG

Country: China

Founded: 1935

Products: CNC flexible modular machine tool and automatic line; Intelligent manufacturing cell and production line; Five axis linkage vertical and horizontal machining center; Vertical and horizontal turning milling compound machining center; High speed and precision machining center; High speed and precision turning center; Industrial robot; CNC system; CNC tool magazine; CNC cutter table; Ball screw; linear guide rail; Electric spindle and high-speed spindle, etc.

About the company:

General Technology Group Dalian Machine Tool Co., Ltd., formerly known as Dalian Machine Tool Factory, was founded in 1935 and is one of the backbone enterprises in the machine tool industry of new China.

In 1995, with Dalian Machine Tool Factory as the core, the main state-owned machine tool enterprises in Dalian were merged as a whole, and Dalian Machine Tool Group Co., Ltd. was established.

In 2000, Dalian Modular Machine Tool Research Institute directly under the former Ministry of Machinery of the People’s Republic of China entered the Group as a whole.

Since 2002, it has successively acquired three old foreign machine tool companies, including Ingersoll Production Systems, Crankshaft and Zmmerman, and has established eight Sino foreign joint ventures with the United States, Germany, Japan, Switzerland, South Korea and other countries.

With the support of the national policy of revitalizing the old industrial base in northeast China, and in combination with the relocation and transformation of enterprises, we have built modern “two bases” (namely, the production base of CNC machine tools and the production base of CNC functional parts) in the Double D Port and Wafangdian, making the comprehensive production and manufacturing scale of CNC machine tools and functional parts rank among the top in the country, becoming the R&D and manufacturing of CNC machine tools, flexible manufacturing systems and complete sets of automation technologies and equipment in China An important base for the industrialization of functional parts.

In April 2019, China General Technology Group strategically reorganized Dalian Machine Tool Group and established General Technology Group Dalian Machine Tool Co., Ltd.

Through the introduction, digestion, absorption, integration and re innovation, Dalian Machine Tool has maintained its leading position in the domestic product level, and some products have reached the international contemporary level.

Nearly 60 major science and technology projects, such as precision machining technology innovation platform for key parts of automobile engines, research and development of CNC functional components, have played the role of Dalian Machine Tools in the national machine tool technology innovation system.

From 2013 to 2016, Dalian Machine Tools accelerated the pace of industrial restructuring, and successively developed 247 domestically leading and internationally advanced new products that meet the requirements of rail transit, new energy and other industries, meeting the development needs of strategic emerging industries for high-end CNC machine tools.

For more than 80 years, the company has successively provided more than 500000 sets of machine tools for China’s automobile, rail transit, engineering machinery, petroleum machinery, mining metallurgy and other industries, and its products have been sold to more than 100 countries and regions in the world, making contributions to China’s manufacturing industry.

7. QCMTT

Country: China

Founded: 1965

About the company:

Qinchuan Machine Tool Group Co., Ltd. (hereinafter referred to as “Qinchuan Group”) owns a number of subsidiaries, including Qinchuan Machine Tool Headquarters, Baoji Machine Tool, Hanjiang Machine Tool, Hanjiang Tools and Walker Gear.

Qinchuan Group is the R&D and manufacturing base of precision CNC machine tools and complex tools in China, and the leading backbone enterprise in China’s machine tool industry.

With the strength of complete industrial chain, numerous product lines, strong system integration capability, and significant comprehensive competitive advantage, Qinchuan Group ranks among the world’s famous machine tool enterprise groups.

As a national high-tech enterprise and innovative pilot enterprise, the Group has established a national enterprise technology center, academician expert workstation and post doctoral research workstation.

By the end of 2020, the Company has a registered capital of 693 million yuan, total assets of 9.218 billion yuan and 10176 employees.

The Group has established the development strategy and the “5221” development goal of “adhering to the host driven, building a strong support for high-end manufacturing and core parts, breaking through the key technologies of intelligent manufacturing and numerical control, and taking the initiative to undertake major national special research and development tasks”, and has lost its ambition to build Qinchuan Group into a leading enterprise in China’s high-end equipment manufacturing industry.

8. Emag

Country: Germany

Founded: 1867

About the company:

EMAG Group, founded in 1867, is headquartered in Salah, near Stuttgart, Germany.

The business of Emag Group is mainly distributed in automobile manufacturing and supporting industry, machinery manufacturing industry, aerospace industry, renewable energy, power and oil industries.

Emag Group provides machine tools and production systems for processing disk parts, shaft parts and box parts, inverted lathes and inverted multi-function production centers.

In 2003, the Shanghai Representative Office of Emag Machine Tool Co., Ltd. was established.

In 2004, Emag Machine Tool (Taicang) Co., Ltd. (now Taicang Branch of Emac (China) Machinery Co., Ltd.) was established.

In 2006, it began to provide localized customized services.

Taicang Branch of Emag (China) Machinery Co., Ltd. is a wholly-owned subsidiary of Emag Holding Group in China, covering an area of 10000 square meters, with 170 employees.

Its sales volume in 2017 was 200 million euros.

At the same time, there are also offices in Beijing and Guangzhou.

Taicang Branch of Emag (China) Machinery Co., Ltd. mainly provides customized services for high-performance inverted CNC turning centers, and sells all products produced by the Group, including inverted lathes, internal cylindrical grinders, external cylindrical grinders, non-circular grinders (including camshaft grinders), crankshaft grinders, gear hobbing machines, laser welding machines, heat sleeve assembly equipment, induction heat treatment equipment, oil pipeline threading machines, and electrochemical processing machines.

It mainly serves the automotive industry, oil exploitation, construction machinery, hydraulic components, aerospace, etc.

Emag Group interprets the high quality of its products with the continuous innovation and rigorous processing concept, which is achieved through exquisite processing technology.

In addition, the quality of Emag also comes from its unique systematic training for Chinese employees, as well as the modern facilities and advanced processing equipment equipped by the factory itself.

It is precisely through these inputs that the quality of Emac machine tools is guaranteed.

All machine tools and production systems of Emag are designed and developed in Germany.

The inverted machine tools and fully automatic integrated systems developed by Emag greatly shorten the feeding and unloading journey and the processing rhythm of workpieces, and make great contributions to the production requirements of improving efficiency and reducing costs.

At the same time, for Chinese customers, high quality and high efficiency are also two important persuasive factors.

In addition, the fully automatic integrated system and its ergonomic design concept make the operation of Emag machine tool more simple and intelligent, thus reducing the load of employees and improving the safety and comfort in work.

9. BOOHI

Country: China

Founded: 2007

About the company:

With the mission of “making good machine tools in China with ingenuity”, BOOHI Machine Tool Group has formed a management mode of “intelligent guidance, double wheel drive, ingenious manufacturing and serving the world”.

It is an important R&D and production base and intelligent manufacturing base of CNC machine tools in China.

It has 12 subsidiaries with a total assets of 2 billion yuan, 3500 employees, an annual output of 20000 machine tools, an income of 3 billion yuan, and a main business income of 30 million dollars from exports, which has been among the forefront of China’s machine tool industry for many years.

Guided by innovation, the company has established a complete R&D, manufacturing and production system integrating talents, technology and brands, and formed a 14 category, more than 200 varieties and 400 specifications product group dominated by intelligent machine tools, flexible processing units, intelligent manufacturing units and automatic production lines, which are widely used in automotive, aerospace, engineering machinery, agricultural machinery, vocational colleges and other fields and industries.

It has undertaken more than 30 national major projects and “brain replacement projects” in 2004, has five major marketing service centers in the world, and has become an equipment supplier guiding the intelligent development of upstream and downstream supply chains in the industry.

Relying on the Shaanxi Branch of the National Research Center for Numerical Control System Engineering Technology, the company is committed to the secondary development of numerical control systems and robots, as well as the in-depth research, development and optimization of intelligent equipment solutions, and joint research and development of a new generation of intelligent machine tools.

The intelligent production line of domestic CNC machine tools and robot auto parts jointly built by us has realized “Made in China” of key auto parts.

Integrate advanced manufacturing technology, big data and cloud platform, accelerate the transformation of intelligent manufacturing mode, and strive to build a “digital factory” by 2024.

BOOHI Machine Tool adheres to the “strategy of strengthening the enterprise with talents and implementing the project of improving the quality of highly skilled talents”, establishes five levels of upgrading channels for skilled talents from technical backbone to “Baoji Craftsman”, creates five levels of employee innovation studios, and forms a multi-level craftsman team and “mass entrepreneurship and innovation” team with highly skilled talents as the core, professional and technical experts as the backbone, and young skilled talents as the backbone.

10. Hision

Country: China

Founded: 2002

Products: Gantry boring and milling, horizontal machining center, CNC turning center, large horizontal boring and milling machine, CNC machine

About the company:

Ningbo Hision Precision Industry Co., Ltd. adheres to the independent brand line, takes “casting high-quality machine tools, revitalizing national industry” as its own responsibility, and constantly develops through technology introduction, absorption, and innovation.

At present, it has nearly 1500 employees and a modern constant temperature workshop of more than 200000 square meters, forming three production clusters with Dagang Seiko, Yanshan Seiko and Dalian Seiko as the main bodies:

Its products rank among the forefront of CNC machine tools in China.

The products are widely used in automobile, locomotive, ship, machinery, power, mold, diesel engine and other industries.

Relying on the production management concept of Hision Group, the company carries out the turnkey project and perfect pre-sales, mid sales and post sales services, so that customers can obtain excellent product efficiency and create the industrial value you want.

Criteria for Selection

When choosing a top CNC machine manufacturer, it is essential to evaluate them based on critical selection criteria that will ensure the acquisition of a machine that meets current and future production needs.

Innovation and Technology

Manufacturers that prioritize innovation often deliver CNC machines embedded with advanced features and capabilities. They provide state-of-the-art equipment that can handle complex designs with exceptional precision. Technology adoption in their product line is indicative of their commitment to staying ahead in a competitive market.

Quality and Precision

The hallmark of a superior CNC machine is the quality of its construction and the precision of its output. Reputable manufacturers focus on robust build quality to withstand rigorous use and precision engineering for accurate and consistent performance. Potential buyers should scrutinize the machines’ abilities to maintain tolerances and reliability.

After-Sales Support and Service

Robust after-sales support is crucial for maintaining machine performance over time. This includes access to spare parts, service technicians, and helpdesk services. A manufacturer’s dedication to service reflects their commitment to customer satisfaction and operational uptime.

Market Presence

A company’s market presence is an amalgam of its reputation, user reviews, and industry footprint. Manufacturers with a strong global presence are typically associated with reliable products and have the financial stability to invest in comprehensive service networks.

Each of these criteria is integral to selecting a CNC machine manufacturer that can offer high-performance machines and sustainable service, ensuring that the investment is sound and future-proof.

Future Trends in CNC Manufacturing

The landscape of CNC manufacturing is continuously evolving. Key trends set to shape the industry involve heightened automation, the expansion of additive manufacturing techniques, and deeper integration of Industry 4.0 technologies.

Automation and Robotics

Automation in CNC manufacturing is rapidly advancing, with leading manufacturers integrating robotics to improve efficiency and precision. Robot-assisted machining has become more sophisticated, allowing for unmanned operations and consistent part production. The incorporation of automated material handling systemsand AI-driven predictive maintenance ensures round-the-clock production and minimizes downtime.

Additive Manufacturing

Additive manufacturing, also known as 3D printing, is transforming CNC from a subtractive process to one where materials are built up layer by layer. This approach allows for more complex geometries and reduces material waste significantly. It’s a complement to traditional CNC machining, offering opportunities for hybrid manufacturing systems that blend both subtractive and additive processes.

Industry 4.0 Integration

Integration of Industry 4.0 into CNC manufacturing signifies a shift towards smart factories and connected systems. Machine learning algorithms improve process optimization and predictability, while the digitalization of the supply chain streamlines production. Moreover, real-time data analytics and cloud computing are enhancing the capabilities and efficiency of CNC machines, making operations more responsive to market demands.