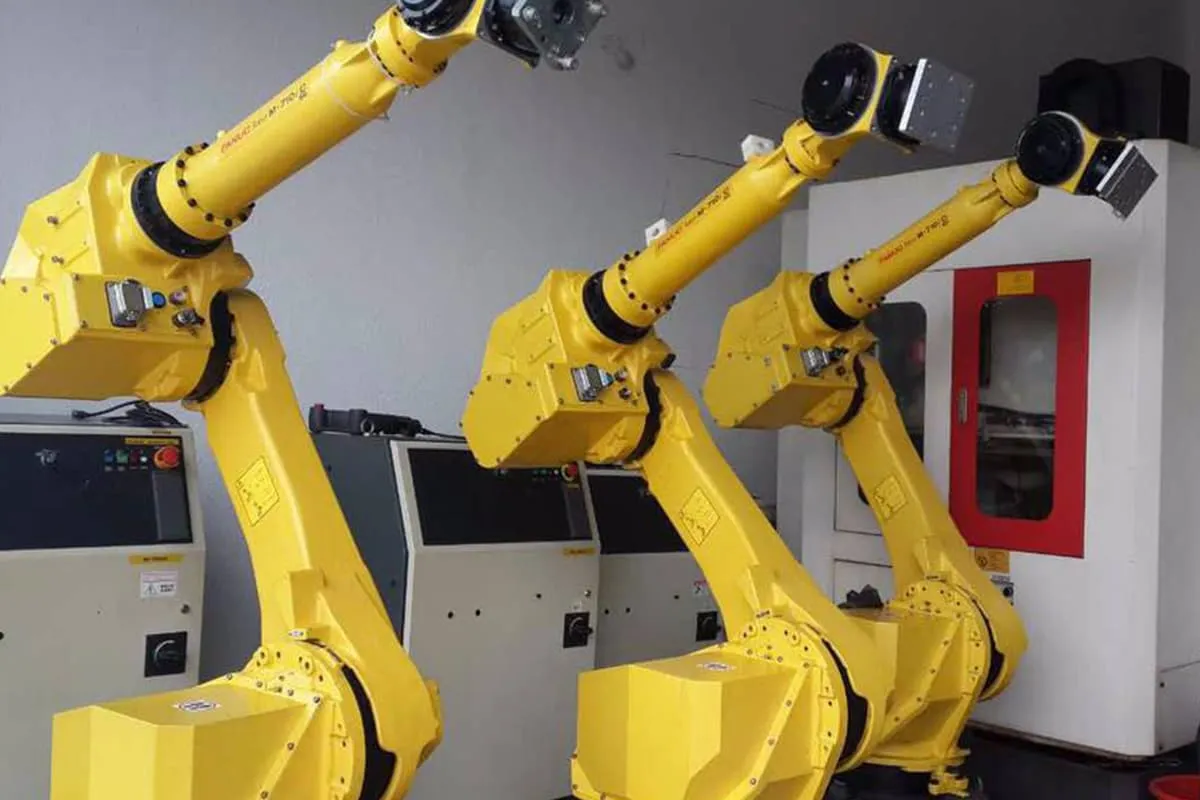

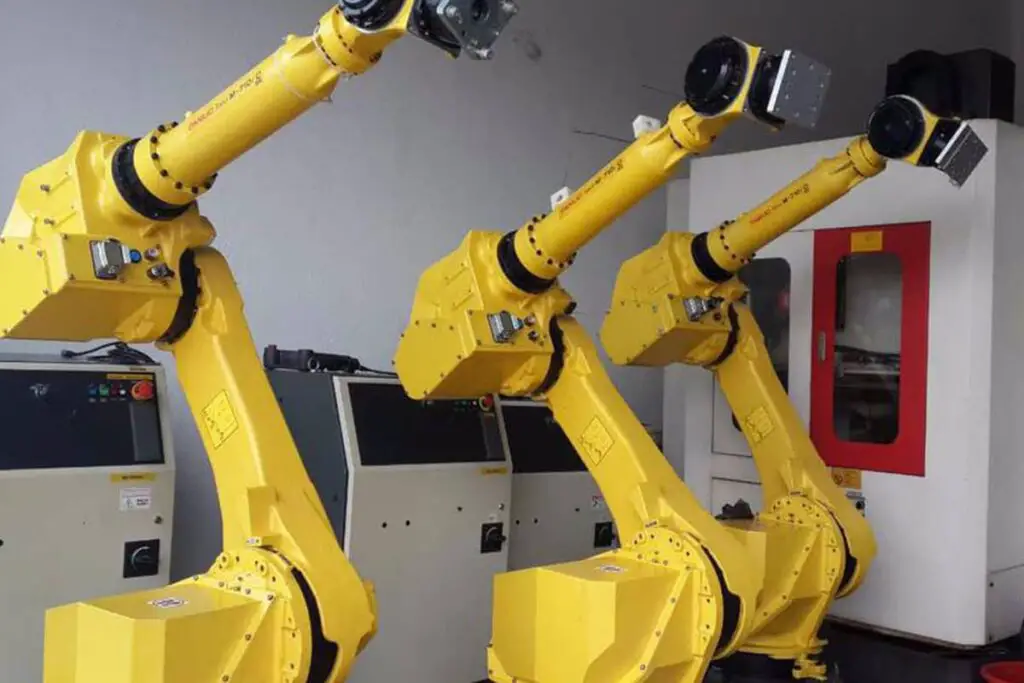

1. FANUC

Since its inception in 1956 in Japan, this leading enterprise has been dedicated to advancing the field of industrial automation. It provides customers with a wide array of highly reliable equipment and automated engineering solutions, including robots, robotic automation projects, and fully electric injection molding machines. The company is committed to continuously enhancing the efficiency and automation levels of customer factories.

FANUC Corporation has established 264 service outlets worldwide, offering technical support to 108 countries and regions.

Shanghai-FANUC Robotics Co., Ltd., a joint venture between FANUC Corporation and Shanghai Electric Group, upholds FANUC’s technological superiority. With its robust engineering integration and technical service capabilities, it delivers products and mature, reliable process solutions along with comprehensive technical services to a wide industrial clientele.

As a global manufacturer in the factory automation industry, the FANUC Group stands out with its formidable research, design, and manufacturing abilities. It provides customers with highly reliable robots, automation projects, fully electric injection molding equipment, high-precision EDM machines, compact machining centers, and complete automated processing projects. These offerings help customers stand out in the fiercely competitive market. FANUC also provides software, control, and vision systems, integrating them into its developed automation projects.

The Baoshan factory spans nearly 60,000 square meters, with about 40,000 square meters dedicated to system integration, including research and manufacturing, installation, commissioning, and factory inspection.

In China, after establishing a new factory in Baoshan in 2002, Shanghai-FANUC successively set up wholly-owned subsidiaries in Guangzhou, Wuhan, and Chongqing. Leveraging the local industrial clusters, it integrates superior technological resources to construct intelligent manufacturing ecosystems. With offices in Tianjin, Taiyuan, Shenyang, Yantai, Liuzhou, Zhengzhou, and other locations, it offers high-quality intelligent manufacturing solutions and timely, thorough after-sales service across the nation.

The Phase III project of Shanghai-FANUC, a collaboration between the FANUC Group and Shanghai Electric Group, is heralded as the “super intelligent factory” of the robotics world. Occupying 431 acres with a building area of 300,000 square meters, it will fully utilize FANUC’s robust engineering integration and technical service capabilities. By employing FANUC’s IoT and AI smart manufacturing technologies, the project aims to create one of the world’s largest robotics production bases outside Japan, encompassing production, R&D, exhibition, sales, a system integration center, and a service headquarters, with an expected annual output value of 10 billion yuan.

2. Yaskawa

Founded in 1915 in Japan, this globally renowned manufacturer of drive products specializes in drive control, motion control, robotics, and systems engineering, focusing on the research, development, design, production, and sales of motor products. Its main offerings include motors, inverters, and industrial robots, with the company entering the Chinese market in 1999.

Since its inception, Yaskawa Electric Corporation has been dedicated to contributing to the rapid development of global industries and striving to realize human dreams. Centered around four key business segments—drive control, motion control, robotics, and systems engineering—Yaskawa contributes to industrial and societal development. With leading quality and technology, the company provides the world with inverter drive products that contribute to environmental protection, support comfortable living, and enhance industrial machinery efficiency and productivity.

Yaskawa coined the term “Mechatronics” in 1969 and has since been committed to the integration of electrical products and mechanics. Starting with the release of the transistor inverter VS-616T in 1974, the company has consistently met customer needs with unwavering quality and innovative products. In 2017, Yaskawa launched the new inverter series—the high-performance multifunctional inverter GA700 and the multifunctional inverter for cranes CH700. These new series inherit Yaskawa’s proud tradition of high quality and, with a versatile, user-friendly, and reliable philosophy, provide suitable “answers” to the challenges customers face.

Yaskawa’s integrated AC servo “Σ Series” product line encompasses AC servo motors, direct-drive motors, linear motors, and actuators for customer machinery, contributing to the high-speed and high-functionality of customer machinery.

Yaskawa robots are active in various industries worldwide, including automotive parts, machinery, motors, metals, and logistics. With the belief in expanding future possibilities using robots useful to humanity, Yaskawa has developed and mass-produced the new generation dual-arm Motoman robots for complex tasks like difficult assembly work.

Yaskawa’s multifunctional robots, with the concept of “providing solutions,” focus on customer communication while offering appropriate solutions for a broader range of needs and diverse problems, supporting the entire FA.CIM system. Today, Yaskawa robots are active in various industries worldwide.

As a company offering comprehensive solutions, Yaskawa Electric (China) Co., Ltd. has been committed to contributing to the advancement of China’s industries since its establishment, continuously providing the Chinese market with world-renowned products and technology. As a leading company in motor control, Yaskawa’s reliable motion control technology meets the needs of the entire world. Moving forward, Yaskawa will continue its mission to “serve human needs and protect the Earth’s environment,” working hand in hand with everyone.

3. ABB

ABB Group ranks among the Fortune Global 500 companies, with its headquarters located in Zurich, Switzerland. It was formed in 1988 through the merger of two companies with over a century of international presence: Sweden’s ASEA and Switzerland’s Brown, Boveri & Cie. ABB is a leading manufacturer in the fields of power and automation technology.

ABB is a global technology leader dedicated to driving transformation in society and industry to achieve a more efficient and sustainable future. ABB integrates intelligent technologies into its electrical, robotics, automation, and motion control products and solutions through software, continually pushing the boundaries of technology and elevating performance to new heights.

Formed in 1988 by the merger of two companies with over 100 years of international heritage—ASEA of Sweden and Brown, Boveri & Cie of Switzerland—ABB has its headquarters in Zurich, Switzerland. With a distinguished history spanning more than 130 years, ABB operates in over 100 countries and regions worldwide, employing a workforce of 105,000.

ABB’s relationship with China dates back to 1907 when it provided a steam boiler to the country. After years of rapid development, ABB has established comprehensive business activities in China, including research and development, manufacturing, sales, and engineering services. It boasts 27 local companies, 15,000 employees across nearly 130 cities, and online and offline channels covering around 700 cities nationwide.

China is ABB Group’s second-largest market globally. Over 90% of ABB’s sales revenue in China comes from locally manufactured products, systems, and services. As a technology leader in the digital field, ABB focuses on China’s “new infrastructure,” strategically positioning itself in key areas such as digitalization, the industrial internet, artificial intelligence, smart manufacturing, intelligent transportation, and smart energy infrastructure. ABB collaborates with Chinese users and partners to inject continuous momentum into the industry’s digital transformation and upgrading.

4. KUKA

Founded in 1898 in Germany, KUKA is a globally recognized leader in industrial robotics manufacturing and an esteemed automation group. The company offers comprehensive one-stop solutions for customers, including robots, work cells, fully automated systems, and networking, catering to sectors such as automotive, electronics, and metals.

KUKA Robotics was established in 1898 in Augsburg, Bavaria, Germany, and stands as one of the world’s foremost advanced industrial robotics manufacturers. With over 20 subsidiaries worldwide, predominantly sales and service centers, KUKA’s reach extends to the United States, Mexico, Brazil, Japan, South Korea, Taiwan, India, and the majority of European countries. The name KUKA is an acronym of Keller und Knappich Augsburg, and it serves as the registered trademark for all the company’s products.

In January 2017, the Chinese home appliance enterprise Midea Group successfully acquired a 94.55% stake in the German robotics company KUKA.

As a renowned automation conglomerate, KUKA boasts a turnover of 3.3 billion euros and employs approximately 14,000 people. Headquartered in Augsburg, Germany, the company positions itself as a global supplier of intelligent automation solutions. KUKA delivers all-encompassing solutions that include robots, work cells, fully automated systems, and networking, serving diverse market sectors such as automotive, electronics, metal, plastic, consumer goods, e-commerce, retail, and healthcare.

5. EPSON

Founded in 1942 in Nagano, Japan, and specializing in the digital imaging sector, we are committed to providing our customers with innovative digital imaging technologies and solutions. Since the 1980s, we’ve entered the Chinese market, primarily producing printers, scanners, projectors, and other information-related products that have won the hearts of numerous consumers.

Epson is a global technology leader headquartered in Japan, with annual sales exceeding 1 trillion Japanese yen worldwide. Epson is dedicated to creating a sustainable society that connects people, things, and information through its original “save, miniaturize, and refine technology” and “digital technology,” striving to make the world more harmonious and beautiful. We continue to innovate in office and home printing, commercial and industrial printing, manufacturing, visual communications, and lifestyle sectors.

About Epson (China) Co., Ltd.

Epson entered China in the 1980s, evolving through phases of trade, factory investments, and comprehensive expansion. After more than 40 years of development, Epson has established a robust manufacturing, sales, and service network.

Epson (China) Co., Ltd. was established in 1998, with its headquarters located in Beijing and twelve subsidiaries nationwide. As the regional head office, it oversees Epson’s investments and business development in China.

Epson’s business operations in China mainly include printers, scanners, projectors, and other information-related products, electronic components, and industrial robots. Our products are cherished by Chinese consumers for their exceptional quality and environmentally friendly features.

6. Estun

Founded in 1993, Estun Automation, a renowned industrial robot brand listed on the Shenzhen Stock Exchange (stock code: 002747), has been dedicated to providing competitive integrated automation solutions. At the core of its business are industrial automation, robots, and digitalization product series. The company’s growth is founded on the principles of integrity, focus, and shared growth, and it maintains a steadfast path of development through independent research and innovation of core technologies. This approach has laid a solid foundation of integrity for the company’s globalization and respect within the industry.

After nearly 30 years of continuous effort from all employees, and thanks to a commitment to investing approximately 10% of annual revenue into research and development, a focus on the complete automation ecosystem, and strong support from a global resource platform, Estun has successfully cultivated three core businesses: industrial automation products, industrial robots, and industrial digitalization products.

As one of the first companies in China to independently develop AC servo systems, Estun’s industrial automation product line includes a full range of AC servo systems, frequency converters, PLCs, touch screens, vision products, and motion control systems. The lineup also features intelligent unit products, such as the Trio control system at its core, which integrates motion control and robotics to provide customers with personalized automation solutions from single-axis to single-machine to single-unit systems.

The company’s industrial robot product line, supported by its own core components, has experienced rapid development. The product range, primarily focused on six-axis robots, covers load capacities from 3kg to 600kg with more than 54 complete specifications. Estun has leading customers and a significant market share in specialized industries such as new energy, welding, metalworking, 3C electronics, engineering machinery, and aerospace.

In 2021, Estun ventured into the field of industrial intelligence and digital manufacturing. Leveraging its control over data entry points for automation equipment, the company offers customers remote access platforms for automation equipment and various digital value-added services through Estun’s unified cloud platform and the OPCUA communication protocol. These services include equipment data collection and edge computing, condition monitoring, process quality control, production efficiency improvement, and material consumption management.

Becoming an international Chinese enterprise is at the heart of Estun’s core development strategy. In addition to multiple subsidiaries in Hubei, Guangdong, and Shanghai within China, Estun also owns or holds shares in foreign companies, including the UK-based Trio, Germany’s Cloos and M.A.i, the Italian R&D center, and a stake in the US-based Barrett. These international ventures give Estun a leading competitive edge in motion control solutions, welding robots, and rehabilitation robots, laying a solid foundation for the company’s international development strategy.

Looking ahead, Estun will continue to create value for its customers and support their growth by focusing on specialized industry solutions and distinctive products. The company will also serve its premium industry clientele, fully utilizing its synergistic advantages in motion control and robotics to provide more competitive integrated automation solutions and chart a unique development path that is distinctly Estun.

7. INOVANCE

Inovance Technology, established in 2003 and listed on the Shenzhen Stock Exchange in 2010, focuses on automation, digitalization, and intelligentization in the industrial sector. It is a pioneer in China’s industrial automation field, boasting significant advantages in core technologies such as motor drive and control, power electronics, and industrial network communication. The company dedicates itself to the R&D, production, and sales of industrial automation control products.

Shenzhen Inovance Technology Co., Ltd., founded in 2003, zeroes in on automation, digitalization, and intelligentization within the industrial realm. The company hones in on core technologies across the “information layer, control layer, drive layer, execution layer, and sensor layer.” It commits to R&D, production, and sales of industrial automation control products, positioning itself as a service provider for high-end equipment manufacturers. Based on industrial automation control technology with proprietary intellectual property rights, Inovance operates primarily by swiftly offering customized solutions to its customers. The company continuously strives to advance industrial civilization with leading technology, rapidly delivering smarter, more precise, and cutting-edge comprehensive products and solutions. As a leading enterprise and listed company in the domestic industrial automation control sector, Inovance Technology has over 30 subsidiaries, including locations in Suzhou, Hangzhou, Nanjing, Shanghai, Ningbo, Changchun, and Hong Kong.

8. YAMAHA

Yamaha Motor Co., Ltd. was established in 1955, and its core engine technologies—including small engine technologies that began with motorcycle development and FRP processing techniques originating from boat hull production—have evolved to include control and component technologies. Over half a century, these advancements have supported the company’s diversification and globalization.

Founded on July 1, 1955, Yamaha Motor Co., Ltd. is a specialist manufacturer of motorcycles. Since 1960, the company has expanded its product line to include personal watercrafts, outboard motors, and automobile engines.

Yamaha Motor Co., Ltd. is a global powerhouse that has repeatedly ranked among the Fortune Global 500. With factories and business entities in various locations worldwide, in 2006, the company invested one billion dollars in the establishment of “Yamaha Motor Trading (Shanghai) Co., Ltd.” in the Zizhu Science Park of Minhang District. This subsidiary primarily exports domestically manufactured Yamaha products to international markets.

As Yamaha’s motorcycle products continued to achieve success, Yamaha Motor Co., Ltd. ventured into the manufacturing of personal watercrafts and outboard motors in 1960. Leveraging their engine and FRP technologies, the company has since expanded into a diverse range of business areas. Today, Yamaha Motor Co., Ltd. not only operates in the motorcycle industry but also manages a variety of businesses including marine operations, power products, automobile engines, intelligent machinery for factories, aviation, and the PAS (Power Assist System) business. This expansion has extended Yamaha’s reach from land to sea, and even to the skies.

9. SIASUN

Founded in 2000 by the Shenyang Institute of Automation at the Chinese Academy of Sciences, SIASUN has emerged as a national industrial base for robotics. Focusing on smart manufacturing as its strategic business direction, SIASUN provides comprehensive core support for industrial upgrades and has evolved into a high-tech listed company centered on robotic technology and intelligent manufacturing solutions.

SIASUN Robot Automation Co., Ltd., established in 2000, is a high-tech listed company at the forefront of robotic technology and intelligent manufacturing solutions. With a creative team of over 4,000 innovators, SIASUN is committed to independent innovation, having completed over 800 significant national tech challenges and holding more than 1,300 invention patents.

As a national industrial base for robotics, SIASUN’s focus on smart manufacturing offers full-system support for the industry’s elevation, crafting a complete industrial value chain that integrates proprietary core technologies, key components, core products, and industry-specific system solutions. The company boasts three main product categories—industrial robots, mobile robots, and specialized robots—along with three technical application directions in welding automation, assembly automation, and logistics automation. Additionally, SIASUN continuously cultivates emerging businesses around the national strategic direction, developing industries such as semiconductor equipment, collaborative robots, smart cities, and intelligent healthcare, thereby establishing a healthy, scientific, and sustainable industrial ecosystem.

With a foundation in China and serving the world, SIASUN’s headquarters are located in Shenyang, with industrial parks in several domestic economic hotspots including Shanghai, Qingdao, Tianjin, and Wuxi. Proactively expanding into the international market, SIASUN has established subsidiaries and regional centers in Singapore, Thailand, Malaysia, Germany, and other locations. The company’s overseas presence includes professional project engineering teams and advanced R&D and production bases, enabling the localization of overseas projects and services. SIASUN’s products have been exported to over 40 countries and regions worldwide, providing industrial upgrading services to more than 4,000 international enterprises, with deep cooperative relationships established with many Fortune 500 companies, and a sizable customer base that accounts for two-thirds of its scale.

Embracing the noble mission “to make the world a better place with robotics,” SIASUN continues to innovate and strive in this new era, maintaining the “China Speed” and setting the “China Standard,” aiming for industry leadership and world-class excellence.

10. CHAIFU

CHAIFU is a provider of automated intelligent manufacturing solutions and a renowned industrial automation company in China that focuses on research, development, and intelligent manufacturing. With the capability to research, develop, and produce the entire industrial chain of robots and automation, the company offers a wide range of solutions in the industrial sector.

Established in 2011, Shanghai CHAIFU Robotics Co., Ltd. boasts a super factory of approximately 35,000 square meters in Shanghai. As a national high-tech enterprise, it specializes in the research and development of core components for intelligent industrial robots, as well as the manufacturing, sales, and service of complete sets of equipment. It is one of the few companies in China with a complete industrial robot industry chain and has been recognized as a Shanghai specialized and innovative enterprise, receiving accolades such as the “Gazelle Enterprise” and “Fast-Growing Enterprise.”

As a leading Chinese industrial robot research and development enterprise, Shanghai CHAIFU has an extensive customer base of over ten thousand companies, both domestically and abroad. Its products are widely used in painting, welding, handling, stacking, polishing, and grinding. Since its inception, the company has earned the trust of many businesses by providing high-quality products, mature and reliable process solutions, and comprehensive technical services. This support helps customers enhance production efficiency and economic benefits!