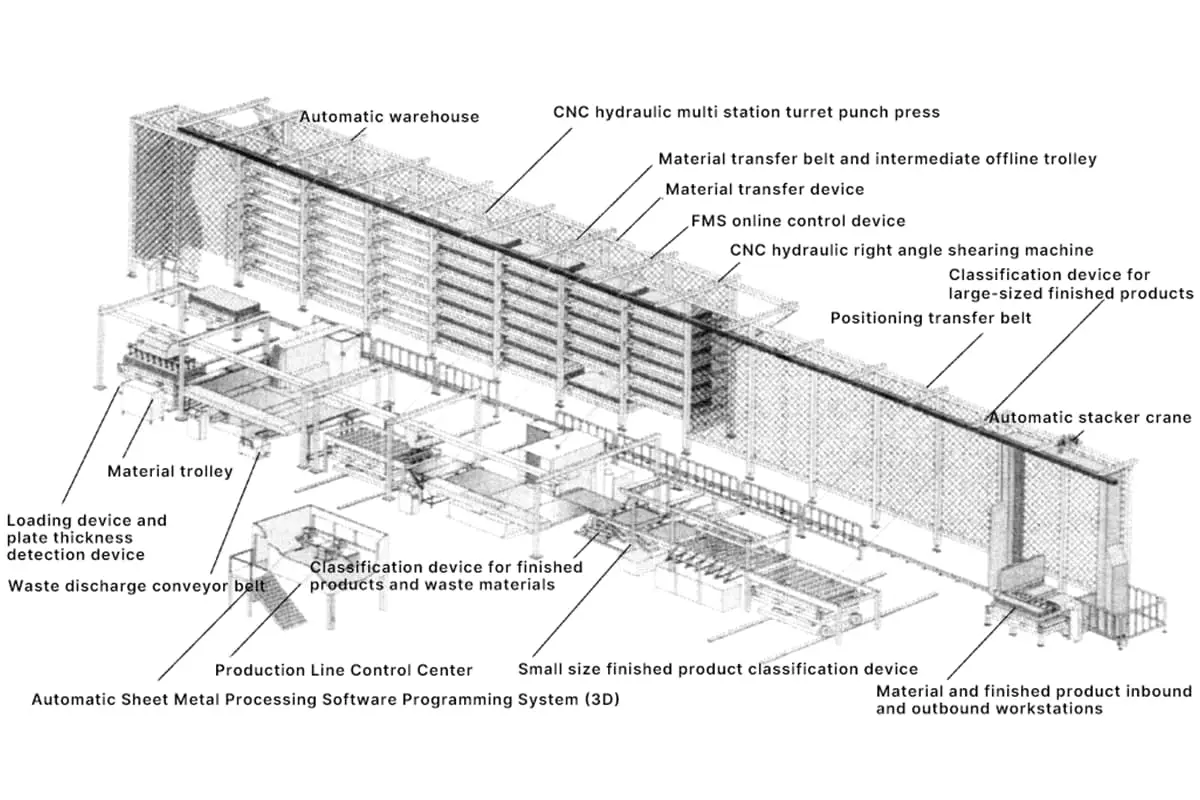

Features of the CNC Turret Punch Press

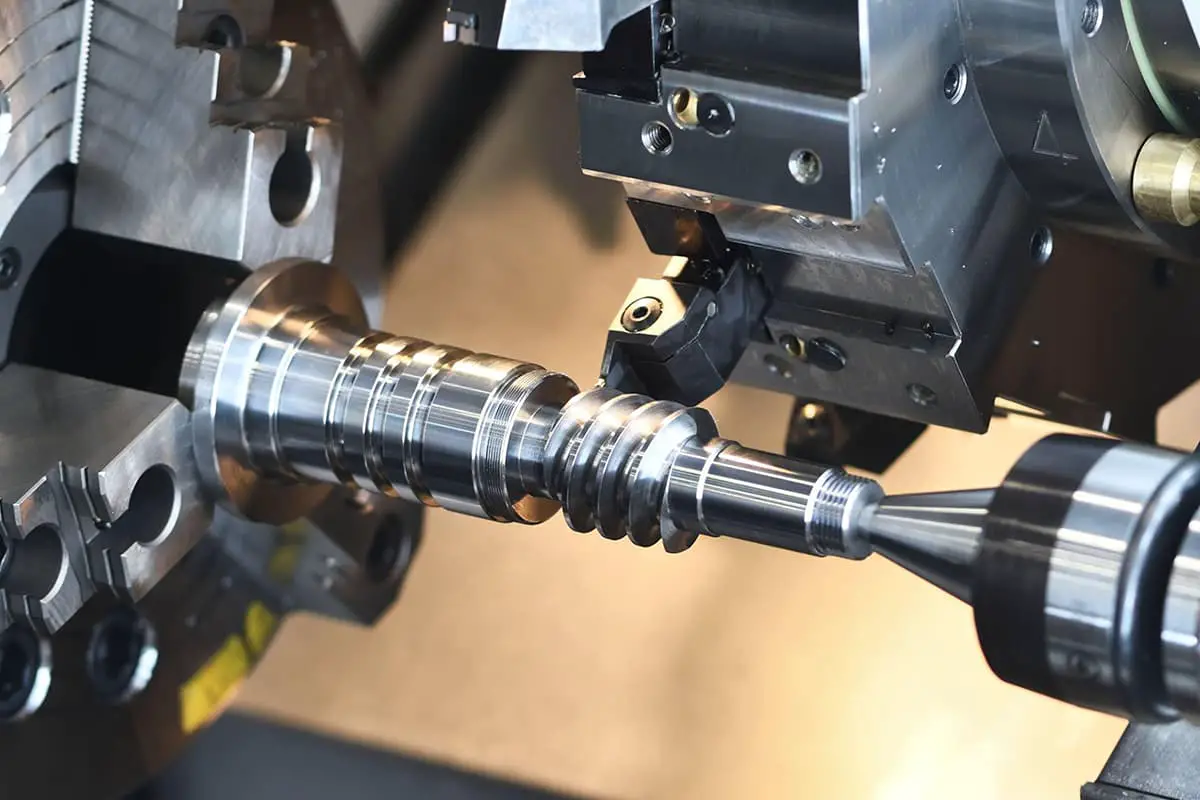

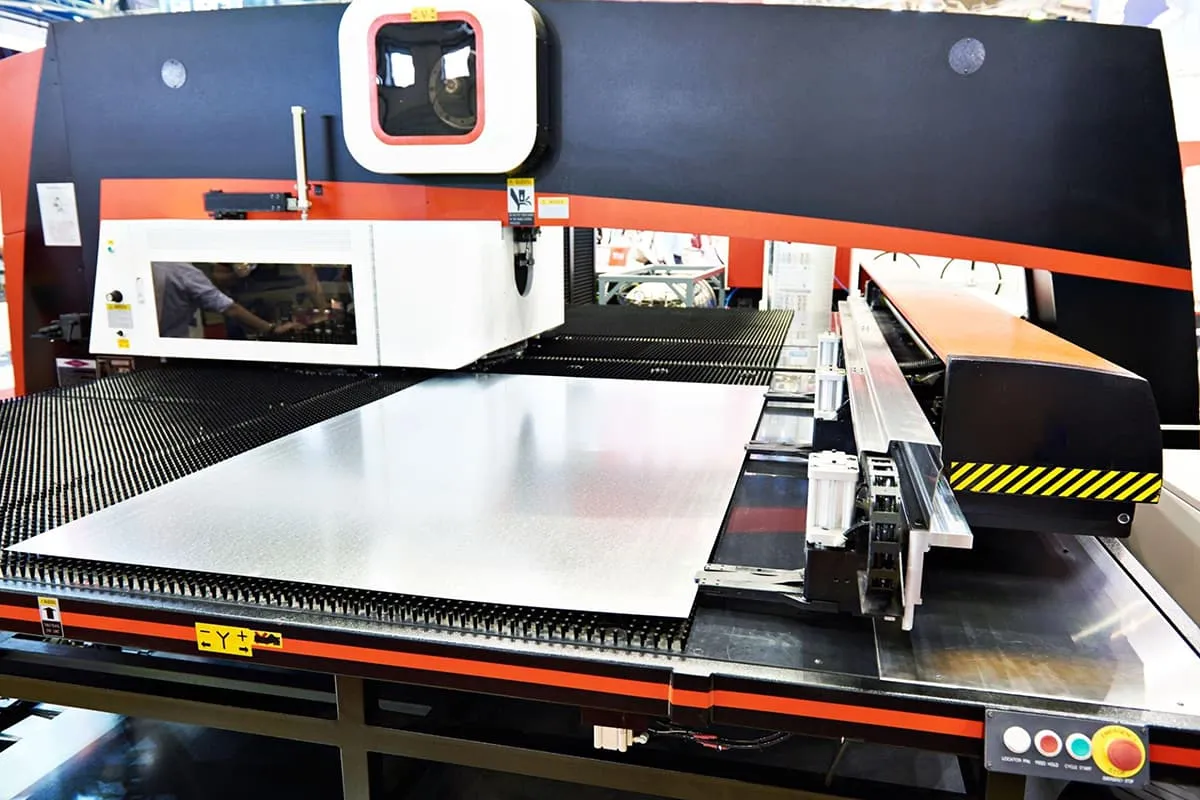

1) It uses high-precision ball screws and rolling guide structures, offering high motion accuracy and reliability.

2) The upper and lower turntables of the turret punch press are equipped with multiple sets of dies for selection during processing, and they have various punching process functions.

3) The CNC system is used, and punching work can be automatically completed by inputting a program. It also has a program storage function.

4) Once the sheet metal is clamped, all the holes on it can be punched out step by step. The combination punching method can be used to punch out more complex holes, or the step-by-step punching method can be used to punch holes that require greater punching force than the nominal force of the punch press.

5) The accuracy of the punched parts is high. The positioning accuracy is generally within ±0.15mm, and the highest can reach ±(0.05~0.07)mm.

6) The production rate is high, increasing efficiency by 4-10 times compared to regular punching. For single pieces or small batch production, the efficiency is increased by 20-30 times, making it suitable for single-item, multi-variety, and small to medium batch punching production.

7) It allows for uninterrupted punching processing. The machine tool operation is convenient, the production process is safe, and the material utilization rate is increased by 10%. It can also crush and handle scrap materials.

8) The production preparation cycle is short, and it can reduce the cost of mold design and manufacturing.

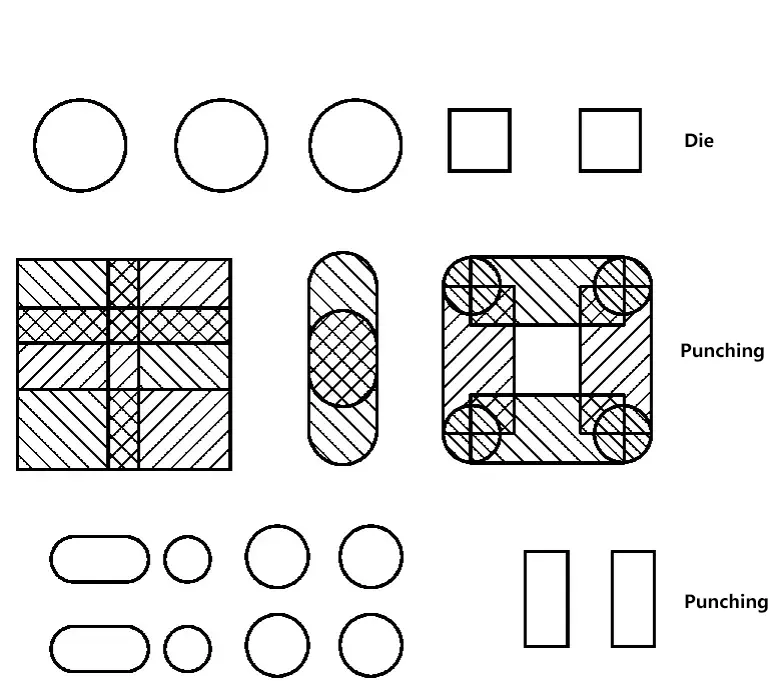

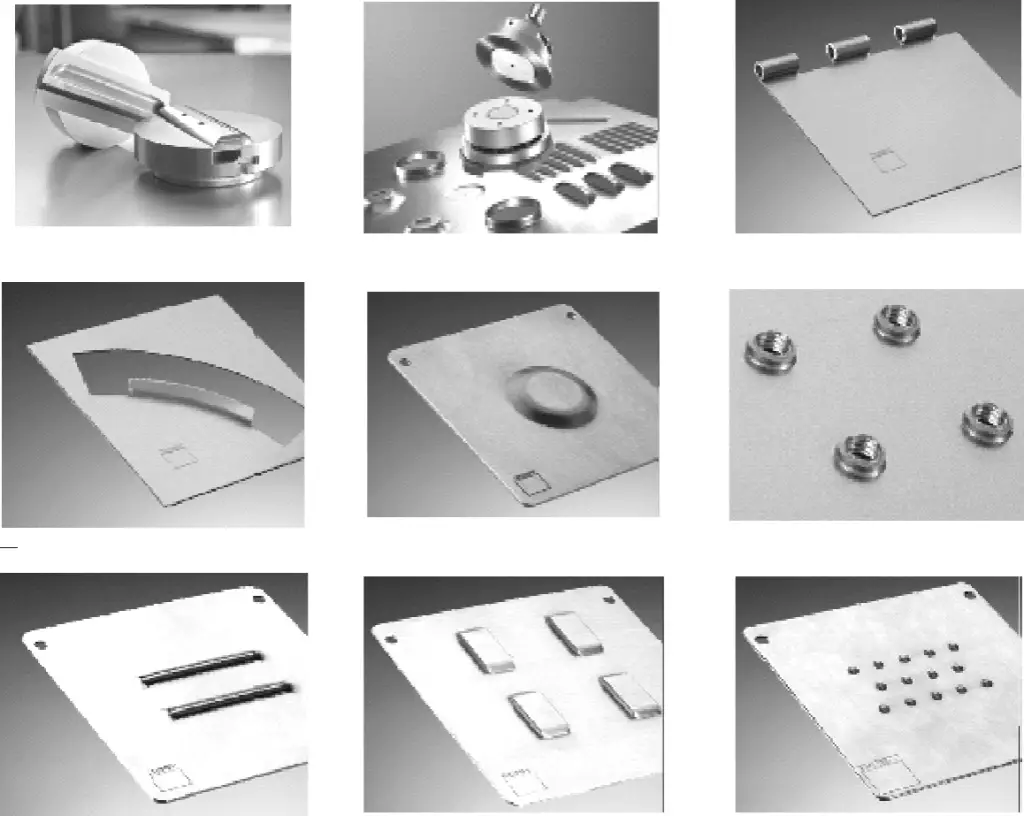

Figure 3-41 shows an example of combination punching with a CNC turret punch press.

Functional Dies of CNC Turret Punch Press

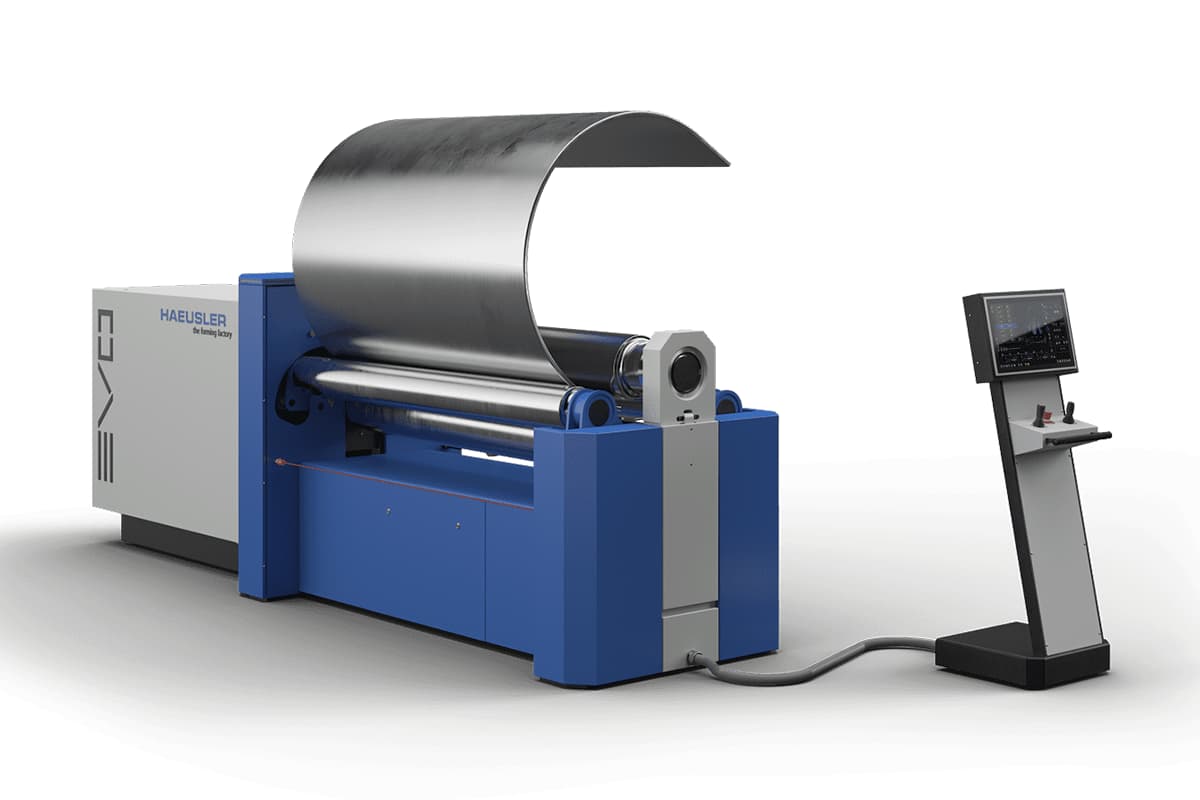

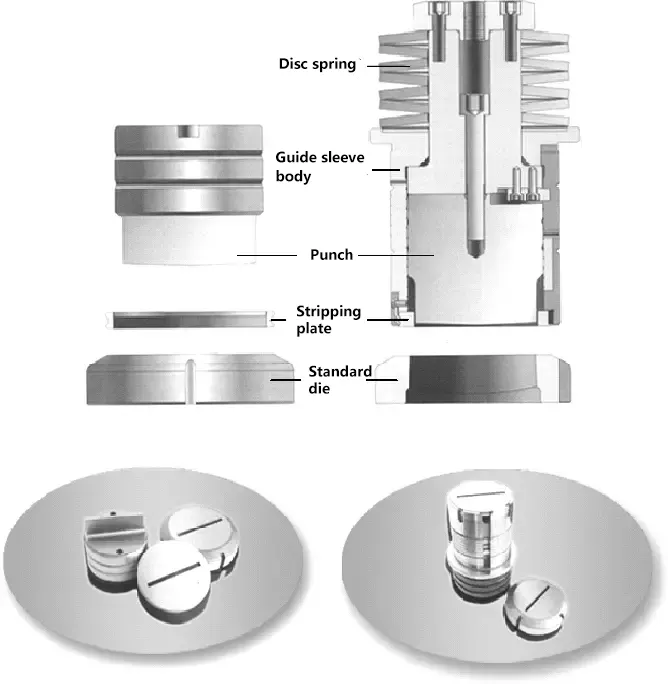

The dies of a CNC turret punch press are characterized by standardized structures and functional cores. Figure 3-42 shows a structural diagram of the dies used in a CNC turret punch press. In terms of function, there are punching and cutting dies, forming dies, marking dies, and bead rolling dies, among others.

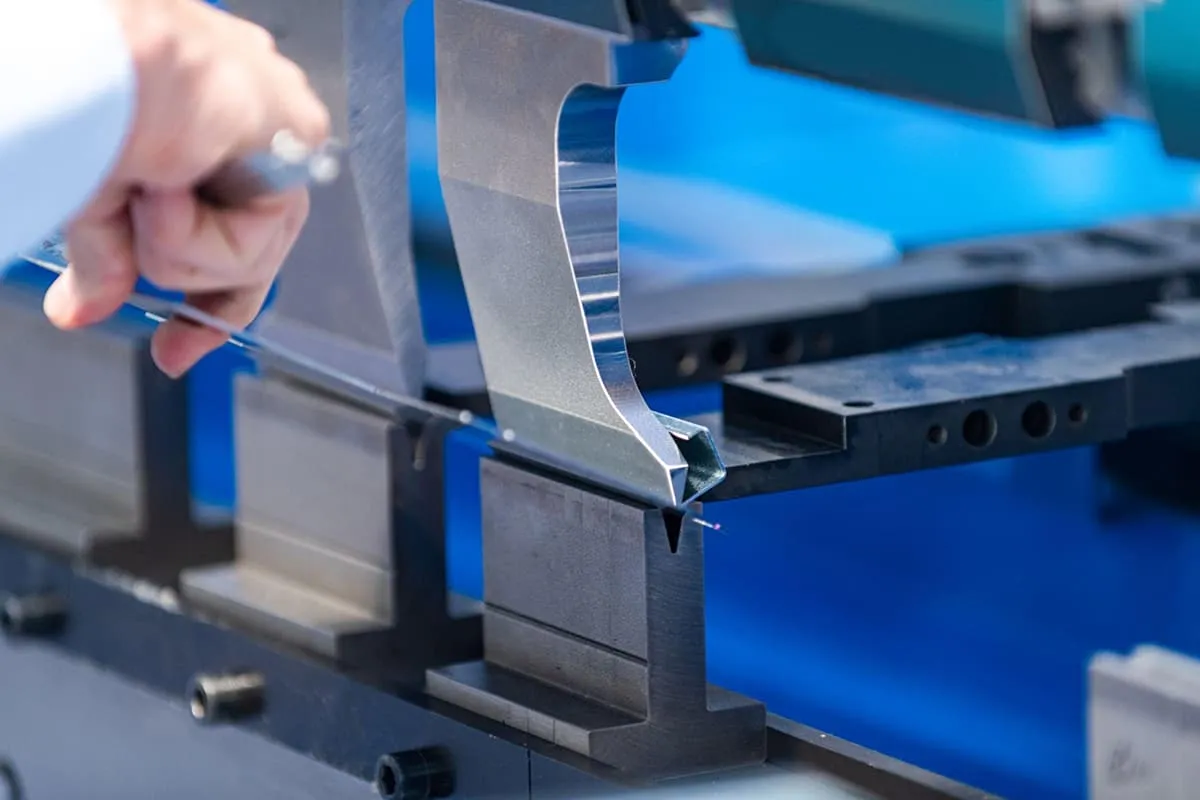

(1) Punching and Cutting Dies: Figure 3-43 shows the external view of the punching and cutting dies.

(2) Forming Dies: Figure 3-44 provides an example of the forming dies and formed parts.

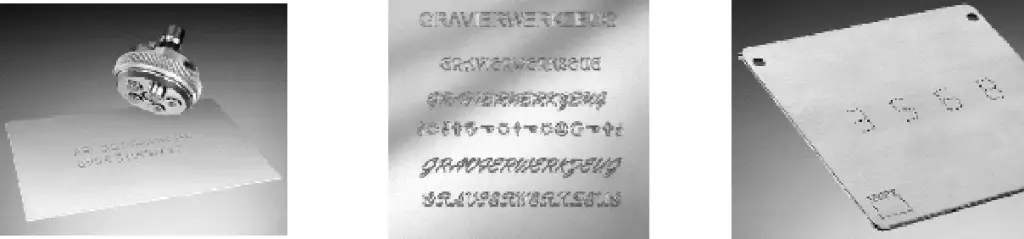

(3) Marking Dies: Figure 3-45 provides an example of the marking dies and marked parts.

(4) Bead Rolling Dies: Figure 3-46 shows the external view of the bead rolling dies used in a CNC turret punch press.