Correctly selecting the capacity of die forging equipment is an important condition to ensure the smooth progress of die forging. If the selected capacity is too small, the metal will be difficult to fill the mold cavity, and it will be necessary to increase the number of strikes, thereby reducing production efficiency; on the other hand, if the equipment capacity is too large, it will waste equipment and increase metal loss, and it is also easy to damage the mold or reduce the service life of the forging die, which is also not conducive to safe production.

1. Empirical formula for calculating hammer tonnage

The empirical formulas for calculating the tonnage of various die forging hammers are shown in Table 5-48.

Table 5-48 Empirical formulas for calculating the tonnage of various die forging hammers

| Equipment | Official | Instructions |

| Double-acting forging hammer | m= (3.5~6.3)kA | m, m1—Mass of the falling part of the hammer (kg) E—Energy of the hammer without anvil (J) A—Horizontal projection area of the forging and flash (cm 2 ), the area of the flash is calculated as half of the warehouse part k—Material coefficient, determined by Table 5-49 |

| Single-acting forging hammer | m1= (1.5~1.8)m | |

| Hammer without anvil | E =(20~25)m |

Table 5-49 Deformation resistance σ and coefficient k of various materials at final forging temperature

| Materials | k | σ/MPa | ||

| Hammer on | Forging press | Hot trimming | ||

| Carbon structural steel [w(C) < 0.25%] | 0.9 | 55 | 60 | 100 |

| Carbon structural steel [w(C) > 0.25%] | 1 | 60 | 65 | 120 |

| Low-alloy structural steel [w(C) < 0.25%] | 1 | 60 | 65 | 120 |

| Low-alloy structural steel [w(C) > 0.25%] | 1.15 | 65 | 70 | 150 |

| High-alloy structural steel [w(C) > 0.25%] | 1.25 | 75 | 80 | 200 |

| Alloy tool steel | 1.55 | 90~100 | 100~120 | 250 |

2. Theoretical Calculation Formula

The theoretical calculation formula for the tonnage of the forging hammer is shown in Table 5-50.

Table 5-50 Theoretical Calculation Formula for Forging Hammer Tonnage

| Forging Shape | Formula | Description |

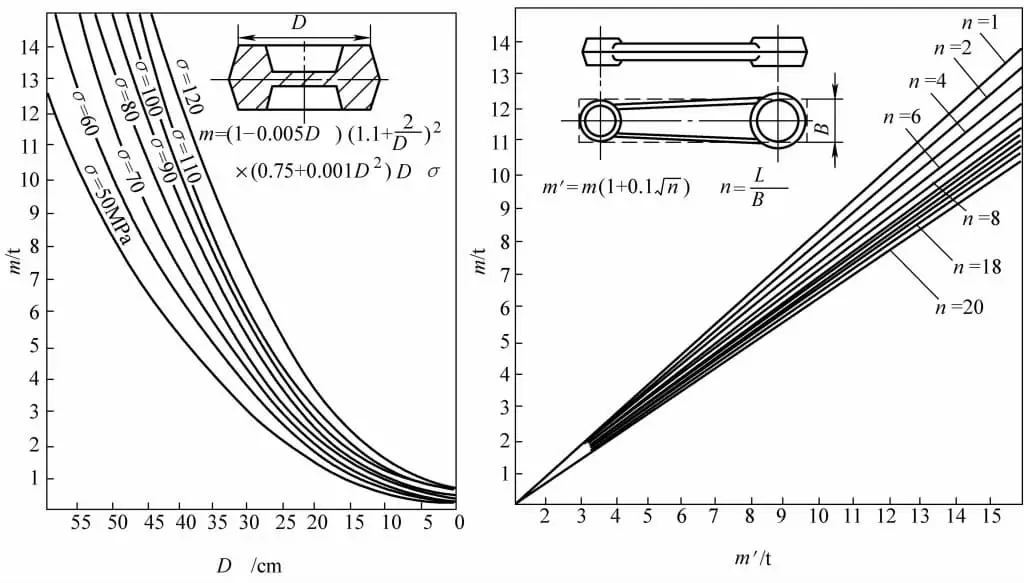

| Circular | m 0 = (1-0.005D) (1.1 + 2 / D) 2 (0.75 + 0.001D 2 ) Dσ | D – Forging Diameter (cm) σ – Deformation resistance of the forging at final forging temperature (MPa) This formula is applicable to forgings with a diameter of less than 60cm |

| Non-circular | m = m 0 (1 + 0.1 √(L/B)) | The maximum length on the horizontal projection surface of the L forging (cm) B – average width (cm), B=A/L A – projected area of the forging (cm²) When calculating m 0 using the above formula, D in the formula should be replaced with the equivalent diameter D e D e = 1.13√A |

Note: The values of m, m 0 calculated using the formula in the table are in kg.

3. Nomogram method

The nomogram for determining the tonnage of the forging hammer is shown in Figure 5-1.

4. Trimming press

Trimming press (see Table 5-51) forms the basic unit of die forging production together with die forging hammers and heating furnaces—a set, with the nominal pressure P (kN) of the press selected based on the tonnage m of the hammer.

P = Mm

In the formula, M is the matching coefficient (kN/t), which varies with the tonnage of the hammer, and can be taken as M=800~1000kN/t.

Table 5-51 Trimming presses matched with die forging hammers

| Mass of the falling part of the die forging hammer /t | Nominal pressure of the trimming press /kN |

| 0.5 | 1000 |

| 0.75 | 1250 |

| 1 | 1600 |

| 2 | 2000 |

| 3 | 3150 |

| 5 | 4000 |

| 10 | 6300~8000 |

| 16 | 12500 ~16000 |

5. Conversion of tonnage of die forging hammers to other forging equipment (see Table 5-52)

Table 5-52 Conversion of tonnage of die forging hammers to other forging equipment (unit: t)

| Serial number | Die forging hammer | Forging press | Friction Press | Counterblow Forging |

| 1 | <0.4 | <400 | <120 | ≤1 |

| 2 | 0.4~0.63 | 400~630 | 120~189 | 1~1.575 |

| 3 | 0.63~1.0 | 630~1000 | 189~300 | 1.575~2.5 |

| 4 | 1.0~1.8 | 1000~1800 | 300~540 | 2.5~4.5 |

| 5 | 1.8~2.5 | 1800~2500 | 540~750 | 4.5~6.25 |

| 6 | 2.5~3.15 | 2500~3150 | 750~945 | 6.25~7.875 |

| 7 | 3.15~6.3 | 3150~6300 | 945~1890 | 7.875~15.75 |

| 8 | 6.3~8.0 | 6300~8000 | 15.75~20 | |

| 9 | 8.0~12 | 8000~12000 | 20~30 | |

| 10 | 12~16 | 12000~16000 | 30~40 |