I. The Purpose and Classification of Ironworker Machines

The ironworker machine is a very widely used metal shearing and separating equipment. It can not only process metal plates and profiles (including round steel, square steel, flat steel, hexagonal steel, angle steel, channel steel, I-beam, T-shaped steel, and other special-shaped steel materials) by shearing and separating, but also perform punching and die cutting (or notching) on the flat parts of plates and profiles.

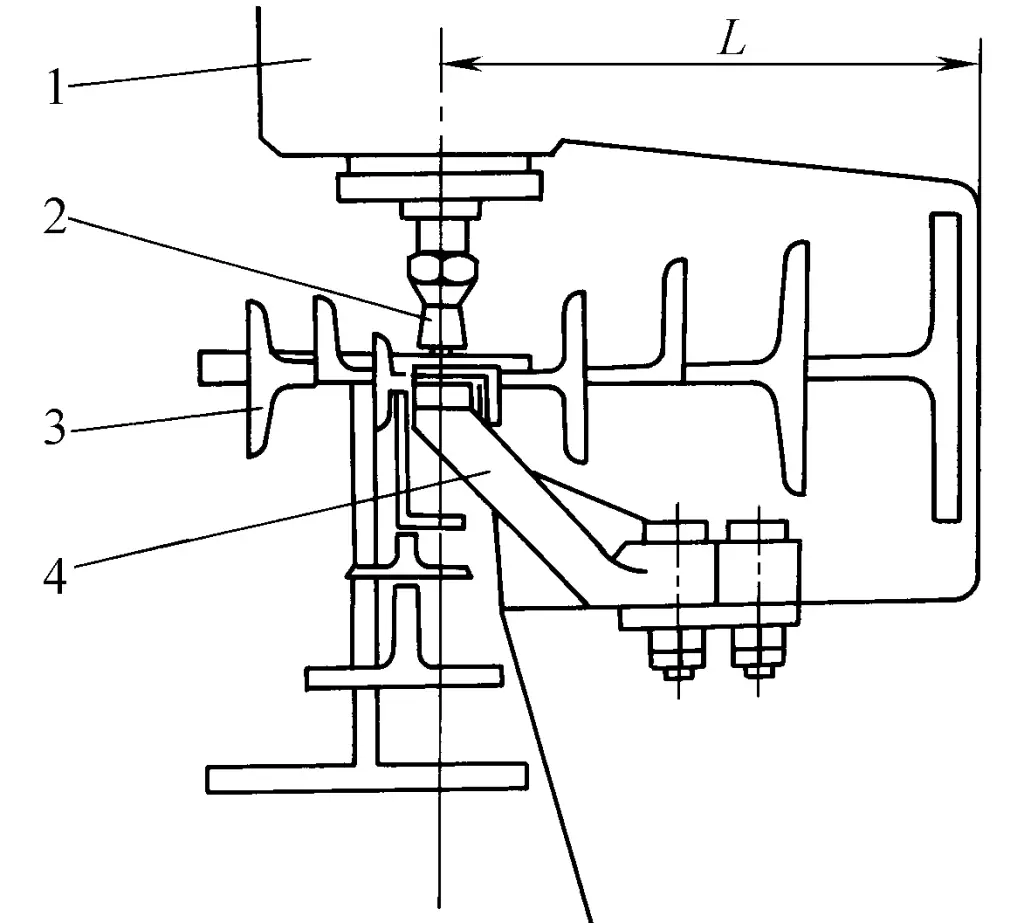

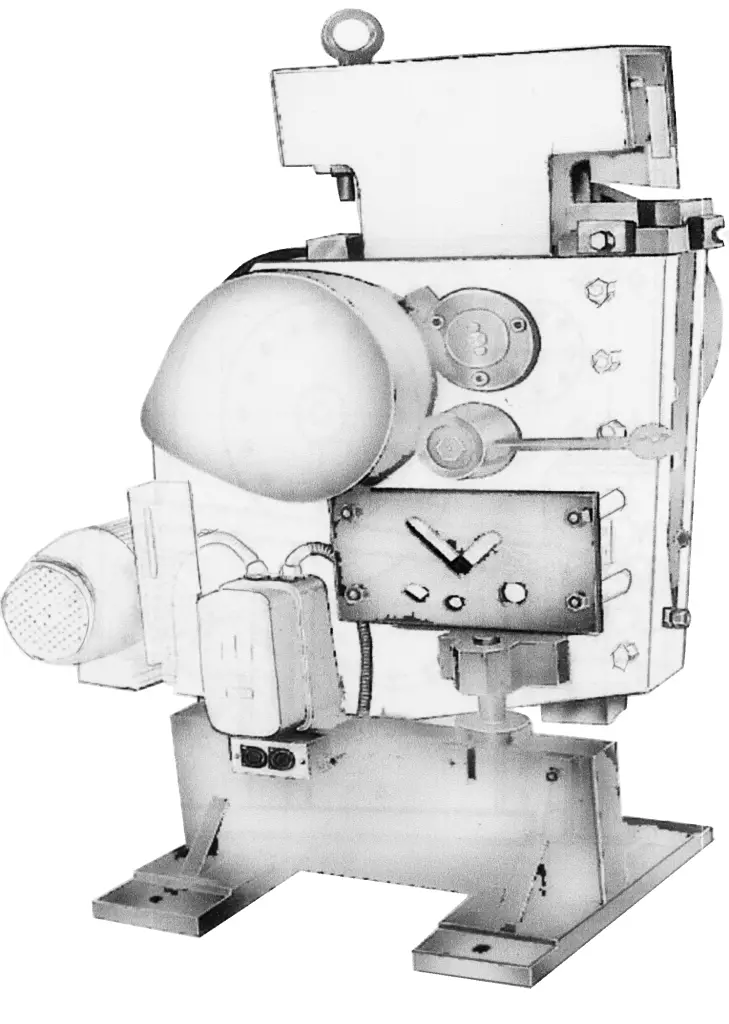

Because it can complete many types of shearing processes, it is called an ironworker machine, see Figure 1.

1—Punching

2—Die cutting

3—Profile shearing

4—Plate shearing

According to the set working mechanisms and the corresponding shearing functions that can be completed, ironworker machines can be divided into the following categories.

1. Punching and profile shearing machine

Equipped with punching and profile shearing mechanisms, it can perform punching on plates and profiles and shearing work on various profiles.

2. Plate and profile shearing machine

In addition to being able to complete the shearing function of plates and strips, it can also perform shearing separation work on profiles.

3. Ironworker machine

Capable of completing the shearing functions of the above two types of shearing machines. It can be divided into an ironworker machine with the shear blade placed vertically and an ironworker machine with the shear blade placed horizontally, the latter being used less due to limitations in the process range.

4. Die shearing ironworker machine

In addition to being able to complete the shearing function of the above shearing machines, it can also perform die shearing work on plates and profiles, that is, cutting out certain shapes of notches on the flat part of the plate or profile, in order to bend profiles such as angle steel into frame-shaped parts.

Due to the general nature of this type of equipment, with a wide range of processes, few auxiliary devices, few functional adjustment mechanisms to improve shearing quality, and simple clamping devices for the shearing parts, it results in lower processing precision, larger dimensional errors, and higher roughness of the fracture surface, so it is mostly used in plate and profile processing workshops and some repair departments with a lot of metal structural parts where precision requirements are not high, such as bridges, boilers, shipbuilding, and construction.

II. Technical parameters of the ironworker machine

According to the regulations for the compilation method of forging machinery models, the main parameter of the mechanically driven ironworker machine is the maximum thickness of the steel plate that can be sheared, while for the hydraulic driven ironworker machine, it is represented by the nominal force at the punching part. Some countries have produced ironworker machines with a maximum shearing thickness of 32mm, 25mm, 20mm, among which the ones capable of 16mm are more common.

Due to the wide range of processes, large-scale ironworker machines bring certain difficulties to structural layout, and at the same time, the utilization rate of the equipment is not high, which cannot fully utilize the processing capacity of the equipment, so the production of large-scale models is less.

Our country has formulated the technical parameter standards for the ironworker machine. Table 1 lists the basic parameters of the ironworker machine in our country. Most of the products listed in the table are already in normal production domestically, and their technical parameters are shown in Table 2.

Table 1 Basic parameters of the ironworker machine in our country (Unit: mm)

| Sheet metal shearing | Shearable plate thickness | 8 | 10 | 12 | 16 | |

| Flat steel (single shear) thickness × width | 10×80 | 12×100 | 16×125 | 20×140 | ||

| Profile shearing | Round steel diameter | 30 | 35 | 40 | 48 | |

| Square steel side length | 25 | 30 | 36 | 42 | ||

| Angle steel | 90° shearing | 63×63×6 | 80×80×8 | 100×100×10 | 125×125×12 | |

| 45° shear | 50×50×4 | 63×63×6 | 75×75×8 | 90×90×10 | ||

| I-beam model | Mechanical transmission | 10 | 12 | 16 | 20b | |

| Hydraulic transmission | — | — | 10 | 14 | ||

| Channel steel model | Mechanical transmission | 10 | 12 | 16 | 20 | |

| Hydraulic transmission | 6.5 | 8 | 10 | 14a | ||

| Die cutting | Thickness | 6 | 8 | 10 | 12 | |

| Width | 40 | 50 | 50 | 63 | ||

| Length | 60 | 80 | 80 | 80 | ||

| Punching | Diameter | 22 | 22 | 25 | 28 | |

| Thickness | 8 | 10 | 12 | 16 | ||

| Nominal force / kN (not less than) | 250 | 315 | 400 | 630 | ||

| Number of strokes / (times/min) (not less than) | Mechanical transmission | 42 | 40 | 40 | 32 | |

| Hydraulic transmission | 28 | 24 | 22 | 20 | ||

| Throat depth L (not less than) | Mechanical transmission | 315 | 355 | 400 | 450 | |

| Hydraulic transmission | 225 | 250 | 315 | 340 | ||

| Sheet metal shearing | Shearable plate thickness | 20 | 25 | 32 | |

| Flat steel (single shear) thickness × width | 25×150 | 30×160 | 36×170 | ||

| Profile shearing | Round steel diameter | 56 | 70 | 75 | |

| Square steel side length | 50 | 56 | 63 | ||

| Angle steel | 90° shearing | 140×140×14 | 160×160×16 | 180×180×18 | |

| 45° shearing | 110×110×12 | 125×125×14 | 160×160×16 | ||

| I-beam model | Mechanical transmission | 22b | 28b | 32c | |

| Hydraulic transmission | 16 | 20b | 25b | ||

| Channel steel model | Mechanical transmission | 22 | 28b | 32c | |

| Hydraulic transmission | 16 | 24b | 28c | ||

| Shearing machine | Thickness | 16 | 20 | 25 | |

| Width | 63 | 80 | 80 | ||

| Length | 100 | 100 | 100 | ||

| Punching | Diameter | 31 | 35 | 35 | |

| Thickness | 20 | 25 | 32 | ||

| Nominal force / kN (not less than) | 800 | 1250 | 1600 | ||

| Number of strokes / (times/min) (not less than) | Mechanical transmission | 32 | 26 | 26 | |

| Hydraulic transmission | 12 | 9 | 7 | ||

| Throat depth L (not less than) | Mechanical transmission | 500 | 560 | 630 | |

| Hydraulic transmission | 355 | 400 | 450 | ||

Note: The tensile strength σ b < 450MPa.

Table 2 Shearing machines produced in China for longitudinal shearing combined with punching

| Product Name | Model | Technical Parameters | ||||||||

| Shearing Thickness/mm | Strokes per Minute/(times/min) | Shearing Specifications/mm | Punching Diameter/mm | Punching Plate Thickness/mm | Motor Power/kW | Machine weight/kg | ||||

| Round steel | Square steel | Angle steel | ||||||||

| Q34-10 | 10 | 40 | Φ35 | 30×30 | 80×50×8 | 22 | 10 | 2.2 | 770 | |

| Q34-16 | 16 | 27 | Φ45 | 40×40 | 125×80×12 | 26 | 16 | 5.5 | 2300 | |

| QA34-25 | 25 | 25 | Φ65 | 55×55 | 150×150×18 | 35 | 25 | 7.5 | 7000 | |

| Q35-16 | 16 | 32 | Φ45 | 40×40 | 125×80×12 | 28 | 16 | 5.5 | 2800 | |

| Q35-20 | 20 | 32 | Φ56 | 50×50 | 160×100×12 | 30 | 20 | 7.5 | 6500 | |

| Q35-25 | 25 | Φ65 | 55×55 | 200×125×16 | 34 | 25 | 13 | 7100 | ||

Note: The tensile strength of the processed material σ b ≤450MPa.

III. Working principle and structural form of the ironworker machine

1. Working principle of the ironworker machine

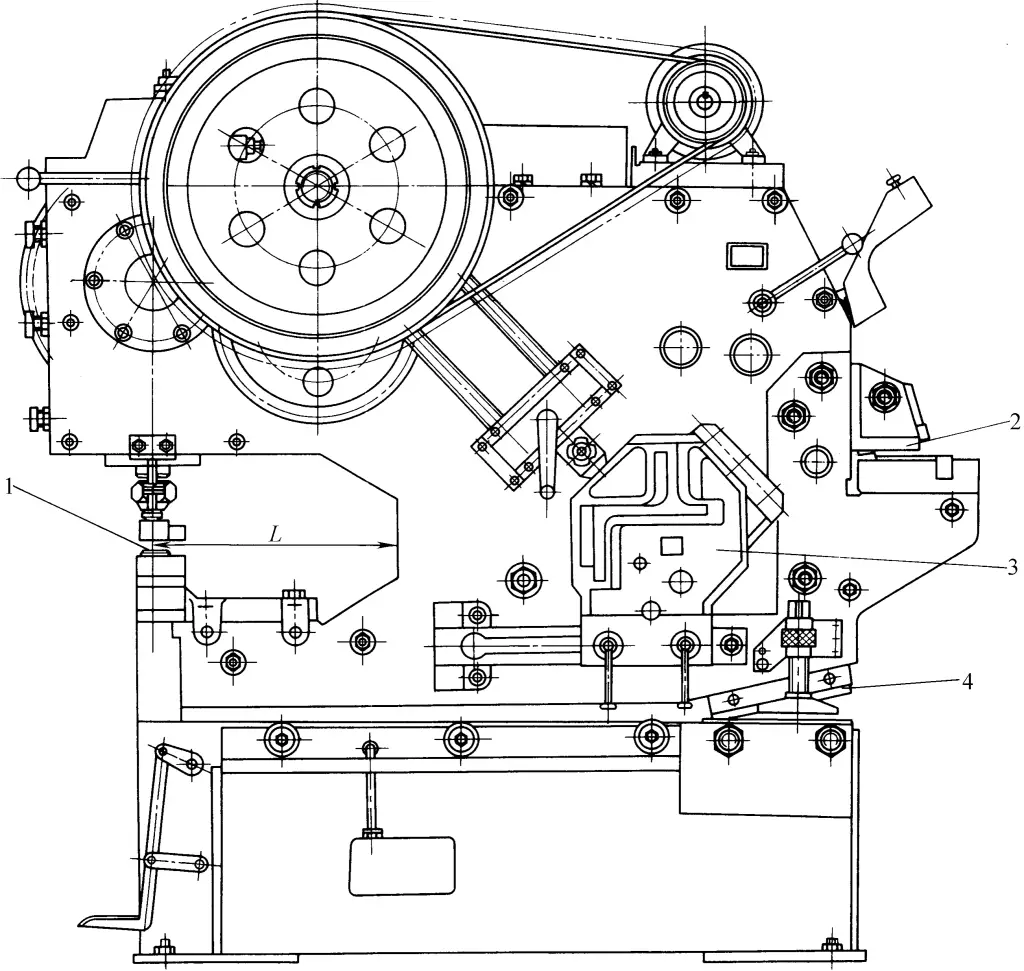

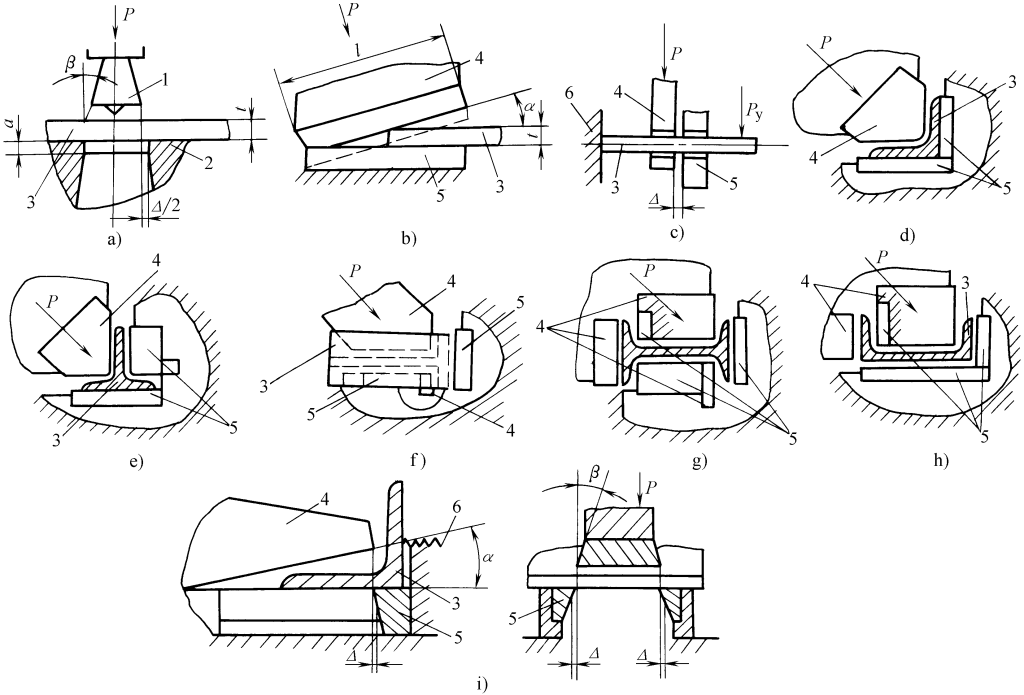

The working principle of the mechanical transmission ironworker machine is similar to that of the general mechanical press and shearing machine. Punching and shearing are performed by the motor driving the slider or blade through the transmission system and crank connecting rod mechanism, enabling the punch on the slider or the blade on the blade to complete the punching or shearing work. Figure 2 shows the working principle diagram of the ironworker machine. Figure 3 shows the punching and shearing process diagram completed by the ironworker machine.

a) Punching

b) Plate shearing

c) Bar stock shearing

d) Angle steel shearing

e) T-beam shearing

f) T-bar reinforcement angle shearing

g) I-beam shearing

h) Channel steel shearing

i) Die shearing

1 Punch upper die

2 Punch lower die

3-processed billet

4-upper blade

5-lower blade

6-material blocking mechanism

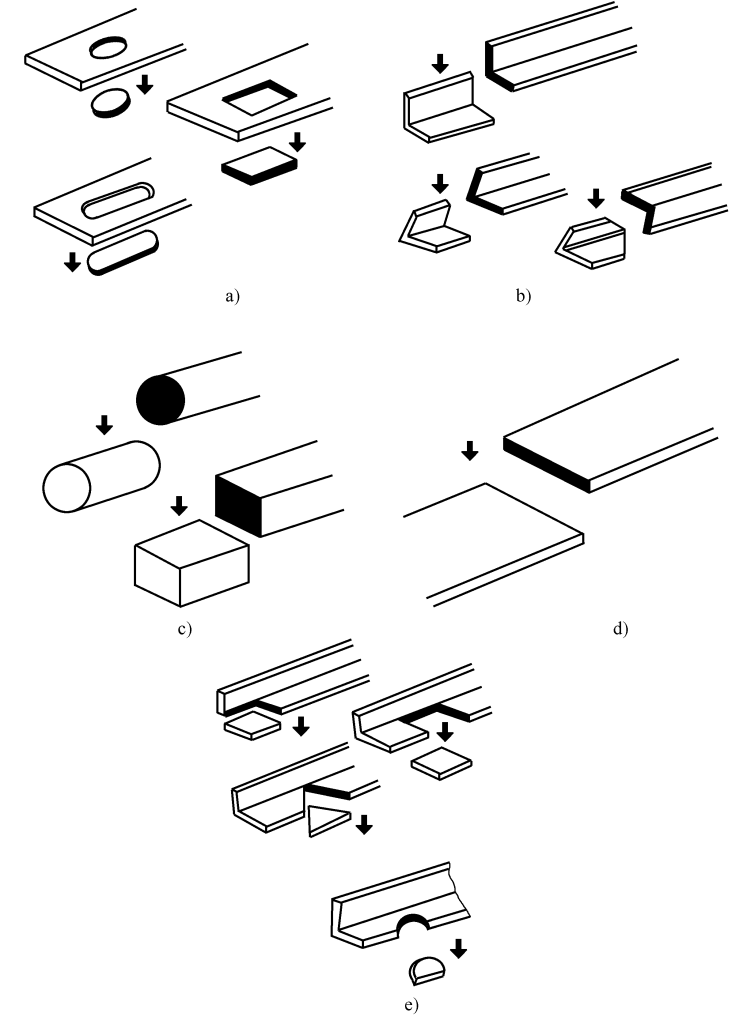

a) Punching round holes, oval holes, rectangular holes

b) Angle steel shearing 90°, 45°

c) Round steel, rectangular steel shearing

d) Flat steel shearing

e) Die shearing 90°, 45°

(1) Punching

The upper die 1 is fixed on the slider (see Figure 2a) and moves up and down reciprocally with the slider, while the lower die 2 is fixed on the workbench. The punching and shearing work is completed when the upper die moves downward. The gap between the upper and lower dies varies with the thickness and mechanical properties of the plate material. Correctly selecting the gap between the upper and lower dies is crucial to ensuring the quality of the punched parts, generally taking a gap value for a plate thickness of 3~10mm.

Δ=(0.06~0.1)t

In the formula

- t-Plate thickness (mm).

When the punching plate thickness is greater than 10mm, take the gap

Δ = (0.1~0.15)t

The blade depth of the lower die is generally taken

a = 3~5mm

Punching on a ironworker machine generally involves relatively simple shaped punched parts, such as those used on the web of plate material, angle steel, the web and flange of channel steel, and the web and flange of I-beam, as shown in Figure 4.

1—Machine body

2—Upper die

3—Profile

4—Lower die

L—Throat depth

Due to the small worktable surface at the punching position and the lack of auxiliary devices, the punching accuracy and production efficiency are lower than those of general presses. Therefore, it is commonly used in structural workshops for auxiliary processes such as punching and riveting holes.

(2) Sheet metal shearing

The upper blade is fixed on the tool holder, which swings around a fixed pivot point to shear, as shown in Figure 2b. The upper blade is inclined at an angle relative to the lower blade, known as the shearing angle. The size of the shearing angle is directly related to the shearing force; the larger the shearing angle, the smaller the shearing force. However, a larger shearing angle will increase the torsional deformation of the sheet metal, reducing the shearing quality.

In the ironworker machine using a swinging tool holder, the shearing angle gradually decreases during the shearing process. The shearing angle is generally set between 8° and 12°. If it is set too large, and the horizontal component of the shearing force exceeds the friction between the sheet metal and the lower blade, the sheet metal will slide out in the direction of the horizontal force, making shearing impossible and likely to cause accidents. Therefore, it is important to choose the correct shearing angle.

The gap size between the upper and lower blades is also an important factor affecting shearing quality. The gap value Δ is mainly selected based on the thickness of the sheet metal being sheared and the mechanical properties of the material, generally taken

Δ=(0.05~0.1)t

where

- t—Thickness of the sheet metal being sheared (mm).

(3) Bar stock shearing

Commonly used are the shearing of round and square bar stock, with the cylindrical or square stationary knife plate fixed on the machine body, and the moving knife plate fixed on the tool holder, moving with the tool holder to shear the blank (see Figure 2c).

Since the aperture (or side length) of the blade on the knife plate cannot change with the diameter (or side length) of the sheared bar stock, that is, the radial clearance cannot be adjusted, and the axial clearance between the moving and stationary knife plates is also inconvenient to change with the different diameters (or side lengths) of the bar stock, coupled with the rigidity effect of the press plate, it results in larger deformation of the sheared section. Therefore, the blanks sheared on the ironworker machine are mostly of medium or smaller size in diameter or side length, and the requirements for shearing quality are not high, with a not too large batch size.

The axial clearance between the shearing blades is an important factor affecting shearing precision, with either too large or too small a clearance value resulting in low quality of the sheared section.

The choice of clearance value mainly depends on the diameter, side length, and mechanical properties of the bar stock. For materials with high strength and brittleness, a smaller clearance value should be chosen, otherwise, a larger clearance value is appropriate. The clearance value for shearing the same diameter of bar stock should be smaller at high speed than at low speed.

For medium carbon steel, high carbon steel, and low alloy steel with a tensile strength of less than 800MPa, the clearance value between the blades is generally taken

Δ = (0.02~0.06)d

where

- d – diameter of the sheared bar stock (mm).

Correctly choosing the axial clearance between the blades is an important condition for obtaining high-quality sheared sections.

(4) Profile shearing

Figures 2d, 2e, 2f, 2g, 2h show the shearing of angle steel, T-shaped steel, I-beam, and channel steel. The shearing force P acts on the shear plane in a direction approximately 45° to the horizontal plane of the profile, which can increase the pure shear surface of the cutting edge, reducing tearing and deformation.

(5) Die shearing

In the upper part of the shear blade of the ironworker machine, a die shearing station is often set up, as shown in Figure 2i, where the upper die 4 moves with the blade, and the lower die 5 is fixed on the body of the machine, capable of cutting rectangular, triangular, or semicircular notches in sheet metal and profiles (as shown in Figure 3e).

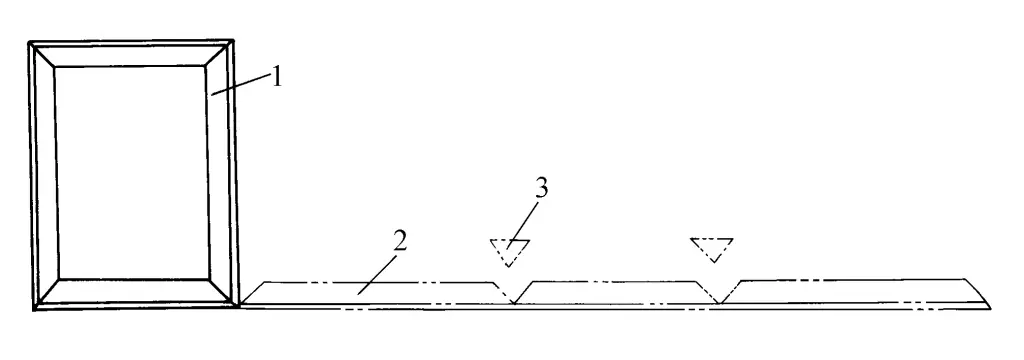

Die shearing is mainly used to notch various profiles for the manufacture of components such as frames, as shown in Figure 5.

1—Frame

2—Blank

3—Scrap cut off

The gap between the die shearing edges is crucial to the quality of the shearing, generally taken

Δ=(0.05~0.1)t

In the formula

- t-Shear material thickness (mm).

The inclination angle of the die cutter blade is shown in Figure 2i.

α=8°~12°

The inclination angle of the cutting edge

β = 2°~3°

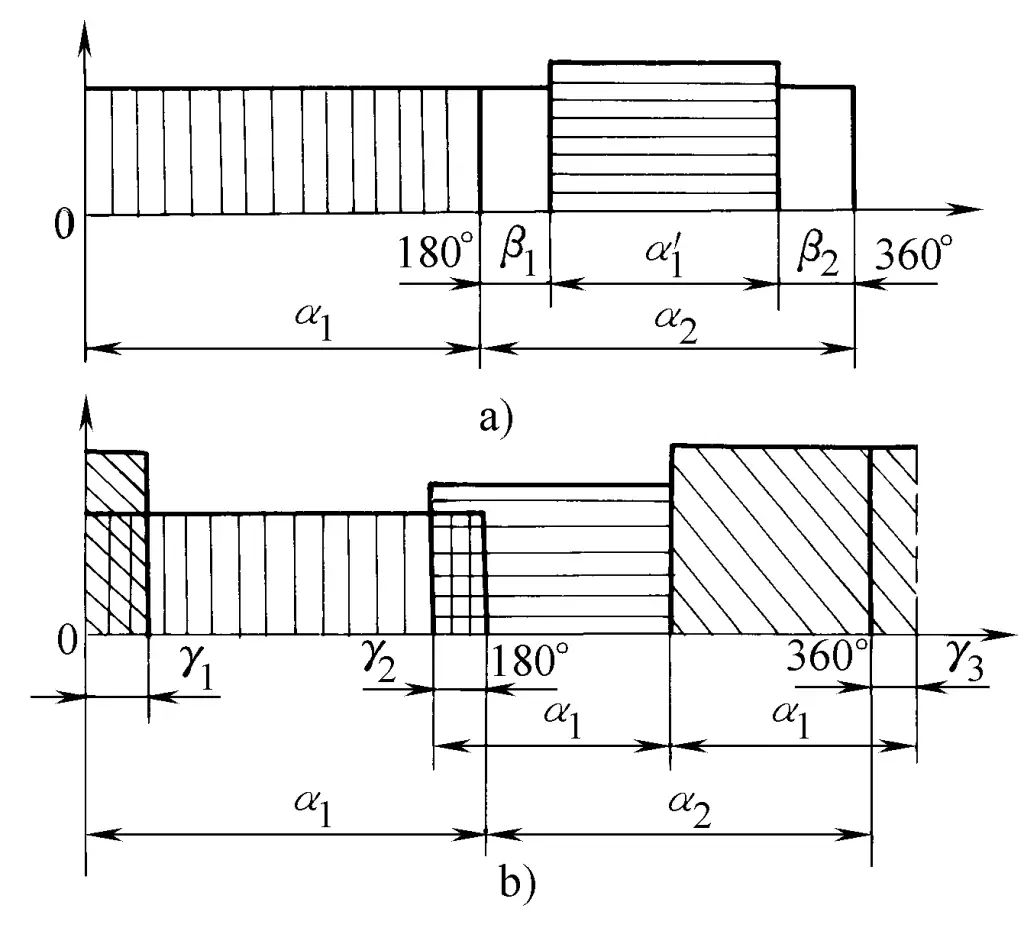

Sheet metal shearing is a basic part of the ironworker machine, and the combined condition for each station is that the shearing work and power of each shearing station are equal. In order to make the structure arrangement reasonable, make full use of the motor power, avoid the machine being too bulky and ensure operational safety, and for the convenience of maintenance, the ironworker machine is not allowed to complete multiple shearing processes at the same time, but must work separately according to a certain work cycle diagram, as shown in Figure 6.

a) Dual-purpose ironworker machine

b) Triple-purpose ironworker machine

In sheet metal shearing, the maximum working angle of the eccentric shaft is 180°, followed by the idle return stroke of the shear blade. On the dual-purpose ironworker machine, the work cycle is as shown in Figure 6a, where α 1 is the angle of rotation of the eccentric shaft during sheet metal shearing, and α 1 ‘ is the angle of rotation of the eccentric shaft during punching (or profile shearing).

The work cycle diagram of the triple-purpose ironworker machine is shown in Figure 6b. There is an overlap between the start and end of the stations, reflected in the overlap angles γ 1 and γ 2 on the eccentric shaft rotation angle, generally taken as 15°.

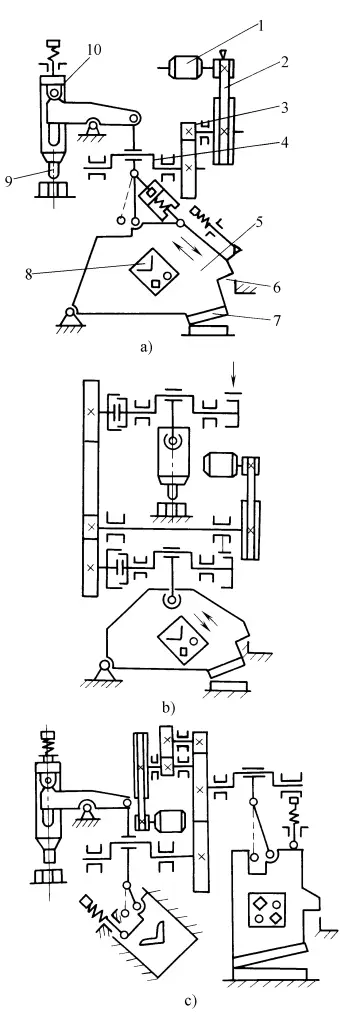

2. Structural forms of ironworker machines

The structure of the ironworker machine is selected based on the needs of the process. For example, in the punching area, an open-type body is used with a certain throat depth to facilitate punching and shearing holes in different positions on the surface of plates or profiles. The opening distance between the worktable and the slider in the punching area is also required to be large to facilitate the installation of punching and shearing dies for channel steel, I-beam, and other special-shaped steel materials.

The plate shearing and die shearing areas are located on the other side of the machine body, facilitating loading and unloading and the shearing of long strip plates. Since profiles are mostly rod-shaped, such as angle steel, channel steel, round steel, etc., the sheared cross-sectional size is small, and the length dimension is large, so the position of the shearing edge is often placed in the belly of the machine body, as shown in Figure 7, in a closed structure. The entire machine body is compactly arranged, which also improves the rigidity of the machine body, conducive to improving the shearing precision of the cross-section.

a) Single eccentric shaft type

b), c) Double eccentric shaft type

1-Electric motor

2-V belt drive

3-Gear reduction system

4-Eccentric shaft

5-Shearing knife holder

6-Die shearing

7-Cut blade

8-Profile shearing

9-Punching upper die

10-punching slider

The transmission system of the ironworker machine mainly includes single eccentric shaft type (see figure 7a) and double eccentric shaft type (see figures 7b, 7c). The single eccentric shaft type has a simple structure, is lightweight, and is more commonly used. The double eccentric shaft type has a more complex structure, is heavier, and some large ironworker machines use this structure.

In the transmission system, the slider of the punching part and the tool holder of the shearing part are driven by an electric motor through a V-belt, gear reduction system, eccentric shaft, connecting rod, and lever mechanism to convert rotary motion into linear reciprocating motion or swinging, driving the slider and tool holder, making the punching upper die, shearing upper blade, upper die of the die shearing part, and the moving blade of the profile shearing part, perform punching and shearing work according to the work cycle diagram respectively.

Springs are installed on the upper part of the punching slider and the shearing tool holder to balance the weight of the slider and punch die, tool holder and blade, ensuring the transmission system operates smoothly and safely.

In addition to the general structure of the ironworker machine, domestic manufacturers have developed the QR32-8 type vertical plate and profile shearing machine as shown in figure 8, with a novel appearance, relatively compact structure, smaller volume, lighter weight, and smaller footprint, making it convenient for a wide range of users in the machinery manufacturing industry, construction industry, and handicraft industry.

The ironworker machine is a multi-purpose steel cutting and punching equipment for multi-variety, small batch production. Compared with presses, shearing machines, and other equipment, it has fewer auxiliary functional components, resulting in lower processing precision and automation level, therefore, it is less used by some large-scale production enterprises.