The main parameters for laser cutting include laser cutting power and speed, lens focal length and focal point position, nozzle shape and distance from the nozzle to the workpiece surface, as well as the type and pressure of the assist gas.

Laser Cutting Power and Cutting Speed

Cutting speed is a crucial parameter for cutting. During cutting, the cutting speed needs to be determined based on the laser power, gas pressure, and workpiece thickness. It increases with the increase in laser power and gas pressure, and decreases with the increase in workpiece thickness. For instance, when cutting a 6mm carbon steel plate, the cutting speed is 2.5m/min, while for a 12mm carbon steel plate, the cutting speed is 0.8m/min.

Lens Focal Length and Focal Point Position (Defocus Amount)

A smaller lens focal length results in higher power density but shallower focus, making it suitable for high-speed cutting of thin materials. Conversely, a larger lens focal length leads to lower power density but deeper focus, making it suitable for slow cutting of thick materials.

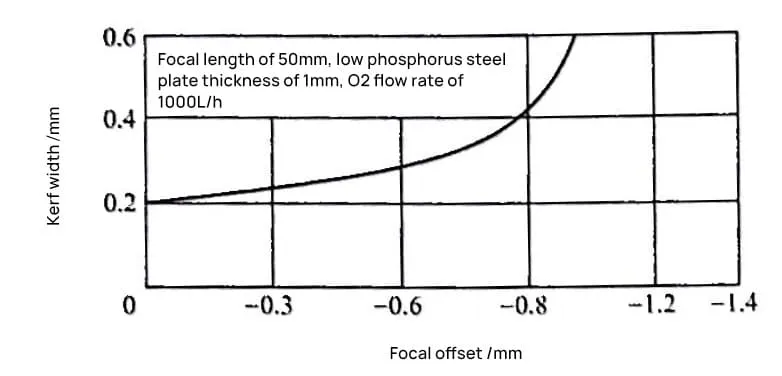

The defocus amount’s impact on the width of the cut is shown in Figure 5-3. Generally, the focal point is chosen to be located approximately 1/3 of the plate thickness below the workpiece surface, at which point the cut width is minimized.

Nozzle Shape and Nozzle-to-Workpiece Distance

(1) Selection of Nozzle Shape

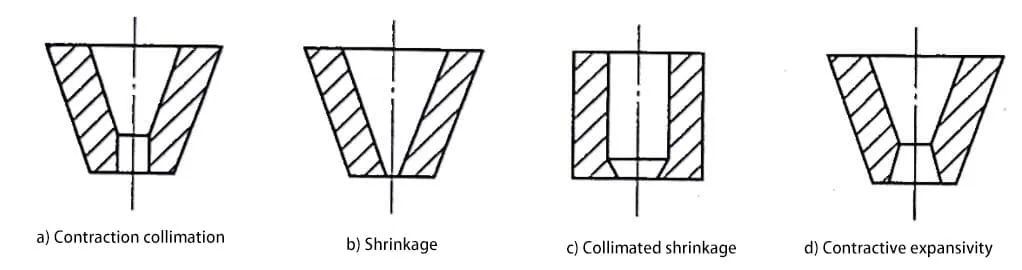

The shape and size of the nozzle are crucial parameters affecting the quality and efficiency of laser cutting. Different cutting methods require different nozzle shapes. Common shapes for laser oxygen cutting nozzles are illustrated in Figure 5-4.

(2) Nozzle-to-Workpiece Distance

When the nozzle is too close to the workpiece surface, it affects the ability to blow away splattered molten slag. However, if the nozzle is too far from the workpiece surface, it can result in unnecessary energy loss. To ensure cutting stability, the distance from the nozzle end to the workpiece surface is generally controlled within 0.5 to 2mm.

Types and Pressure of Assist Gas

When using oxygen as the assist gas for cutting low carbon steel, intense oxidation reactions generate a large amount of heat, increasing cutting speed and thickness, and producing slag-free cuts. For cutting stainless steel, a mixture of oxygen and nitrogen is often used, resulting in better cut quality compared to using oxygen alone.

Increasing gas pressure enhances slag removal capability and can lead to higher cutting speeds. However, excessive pressure can result in rough cutting surfaces. See Table 5-1 for the main parameters and characteristics of laser cutting.

Table 5-1: Main parameters and characteristics of laser cutting

| Workpiece Materials | Workpiece Thickness (mm) | Laser Power (W) | Cutting speed (cm/min) | Cutting gas | Characteristics and Applications |

| 99% alumina ceramic | 0.7 | 8 | 30 | — | Controlled fracture |

| Crystalline quartz | 0.81 | 3 | 60 | — | |

| Ferrite sheet | 0.2 | 2.5 | 114 | — | |

| Sapphire | 1.2 | 12 | 7 | — | |

| Quartz tube | — | 500 | 400 pieces per hour | — | Material saving and high-quality cutting when cutting quartz tubes, suitable for manufacturing halogen lamp tubes |

| Fabric | — | 20~250 | 500~300 | Air | Material saving, high-quality cutting, high efficiency, self-locking edges when cutting fabrics, suitable for manufacturing typewriter ribbons, umbrella surfaces, clothing, etc. |

| Glass tube | 12.7 | 20000 | 460 | Air | High-quality cutting of glass tubes without tool wear |

| Oak | 16 | 300 | 28 | Air | High-quality cutting of wood, neat cutting edges, material saving, suitable for furniture manufacturing |

| Pine | 50 | 200 | 12.5 | Air | |

| Boron epoxy resin board | 8.1 | 15000 | 165 | Air | High efficiency when cutting boron epoxy resin boards, no tool wear, suitable for aircraft component manufacturing |

| Low carbon steel | 1.5 3 1.0 6.0 16.25 35 | 300 300 1000 1000 4000 4000 | 300 200 900 100 114 50 | Oxygen | High-quality cutting, labor and material saving, can replace milling, punching, and shearing, used in the manufacturing of instrument panels, heat exchangers, and automotive parts |

| 30CrMnSi | 1.5 3.0 6.0 | 500 500 500 | 200 120 50 | Oxygen | Can replace milling, punching, and shearing, high cutting efficiency, high-quality cutting, used in aircraft component manufacturing, no cutting deformation, material and labor saving, used in the manufacturing of aircraft components, helicopter rotors, etc. |

| Stainless steel | 0.5 2.0 3.175 1.0 1.57 6.0 4.8 6.3 12 | 250 250 500 1000 1000 1000 2000 2000 2000 | 450 25 180 800 456 80 400 150 40 | Oxygen | No cutting deformation, material and labor saving, used in the manufacturing of aircraft components, helicopter rotors, etc. |

| Titanium alloy | 3.0 8.0 10.0 40.0 | 250 250 250 250 | 1300 300 280 50 | Oxygen | Fast cutting speed, high-quality cutting, can replace milling, grinding, and chemical etching, labor saving, high cutting efficiency, used in aircraft component manufacturing |

| Titanium-clad aluminum honeycomb panel | 30 | 350 | 500 | Oxygen | No cutting deformation, no damage to the workpiece surface, fast cutting speed, used in aerospace component manufacturing |

| Double-sided coated steel plate | 0.5~2.0 | 350 | 300 | Oxygen | Labor and material saving, does not damage surface coatings during cutting, used in air conditioning manufacturing |