Characteristics of Laser Cutting

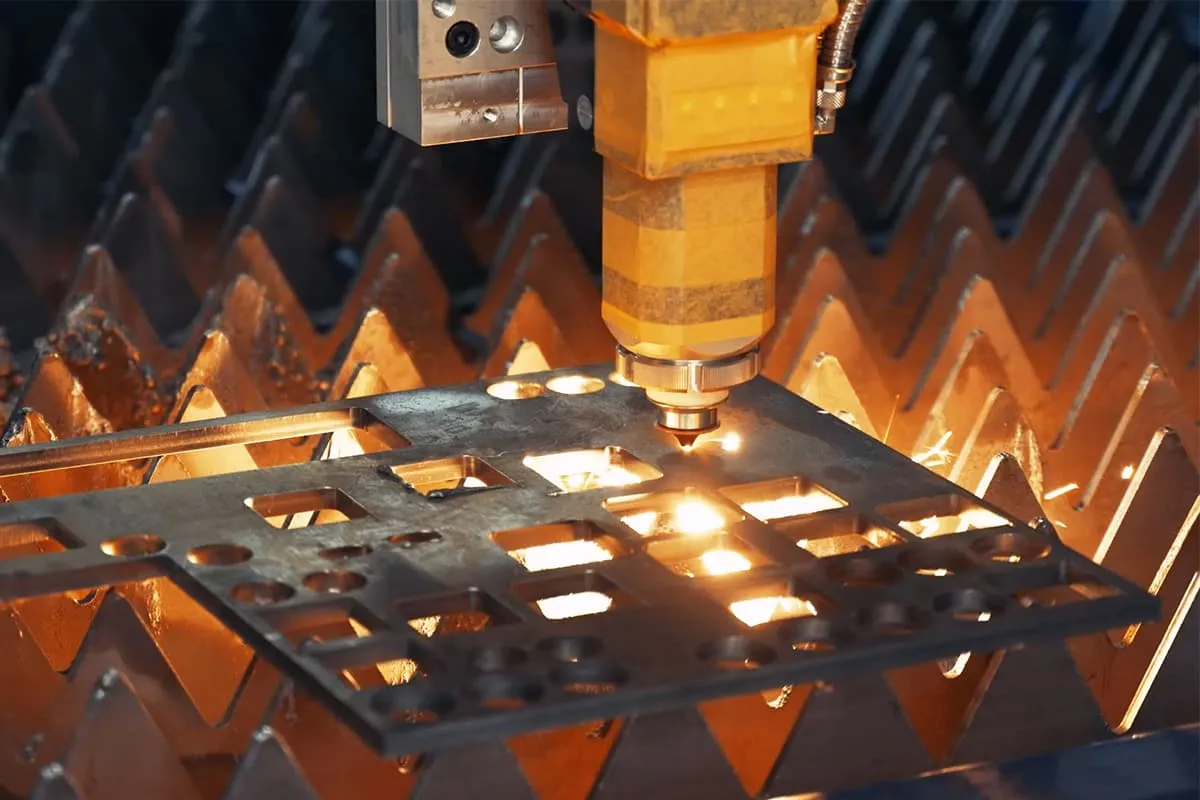

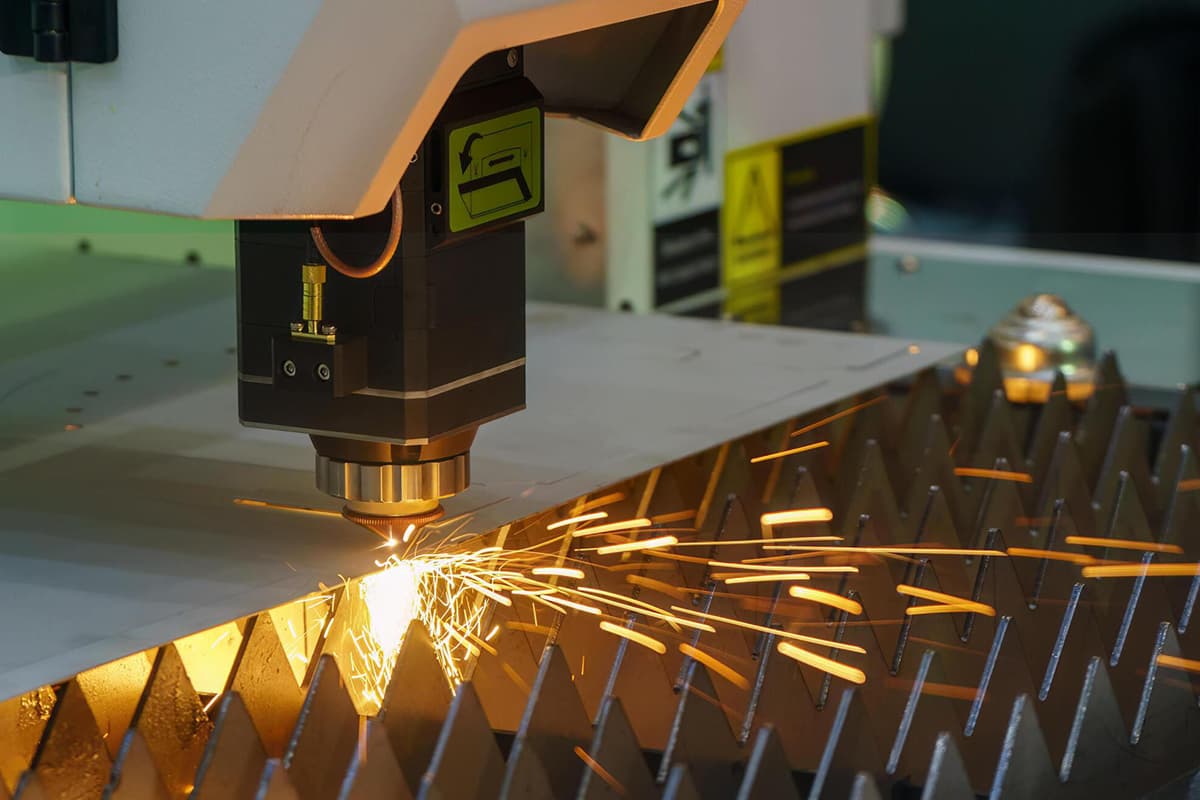

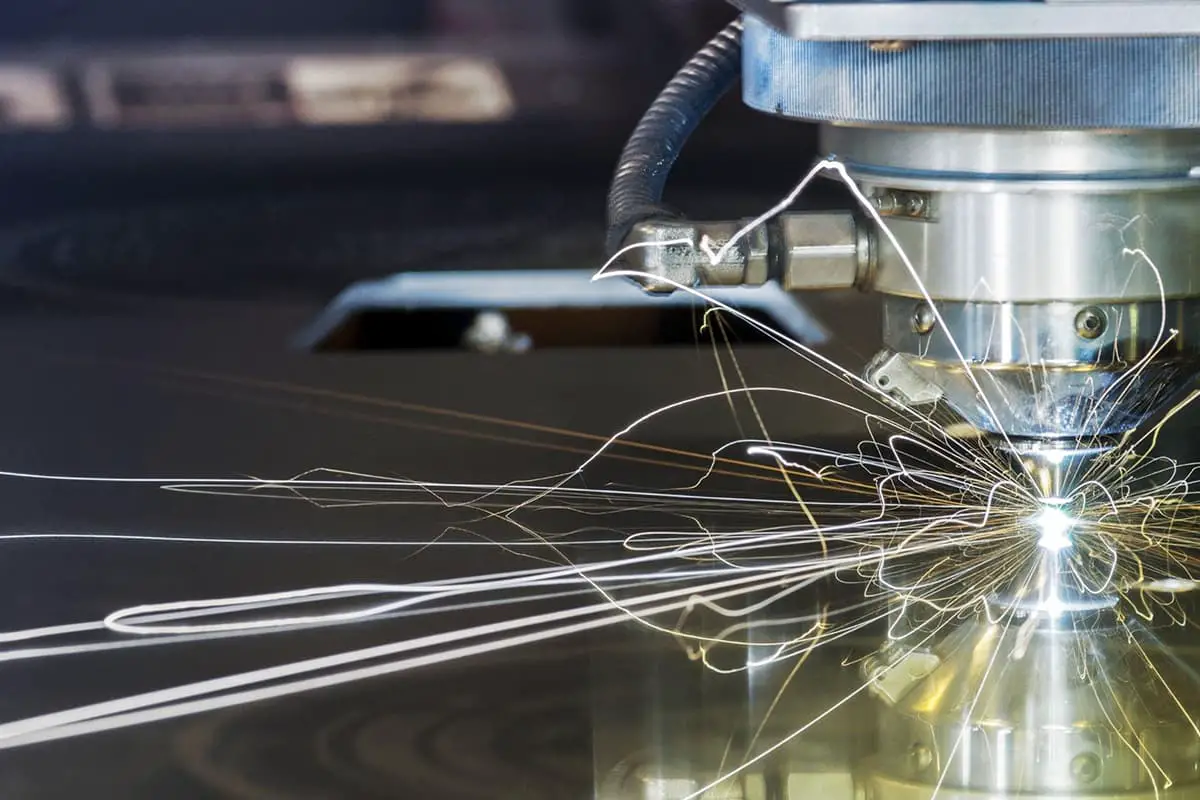

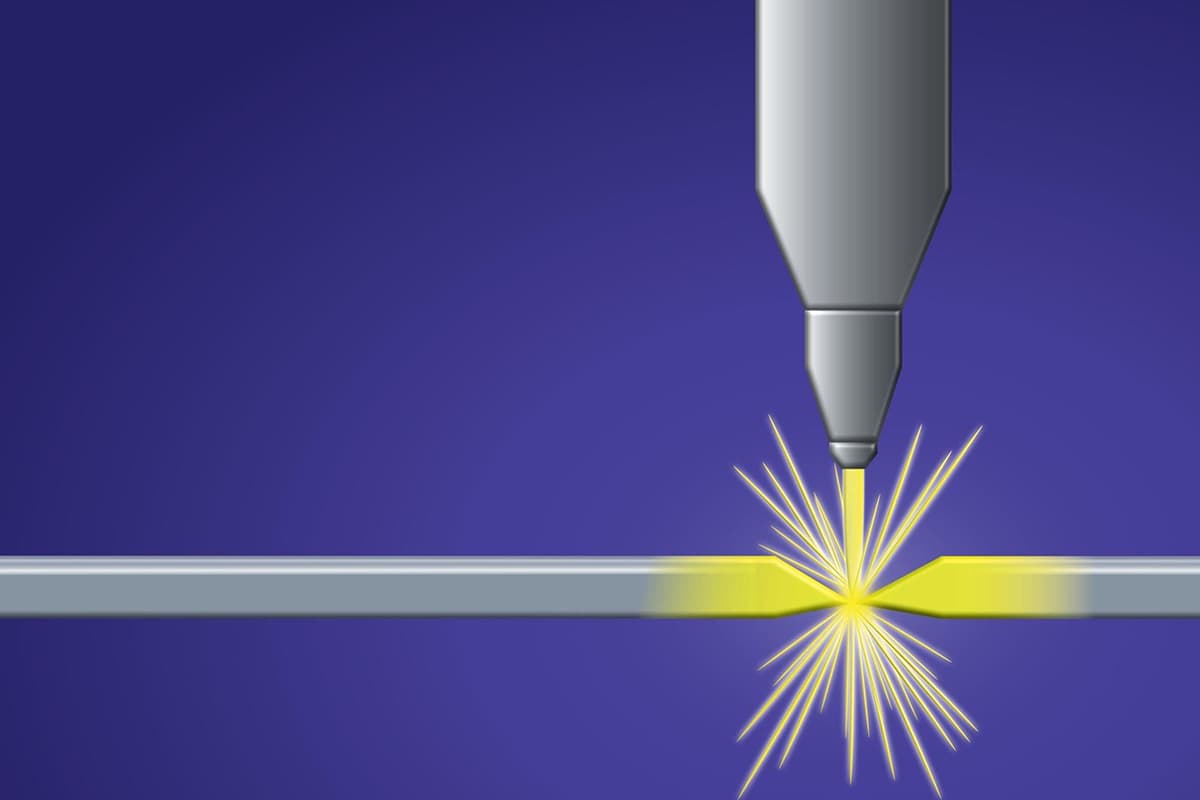

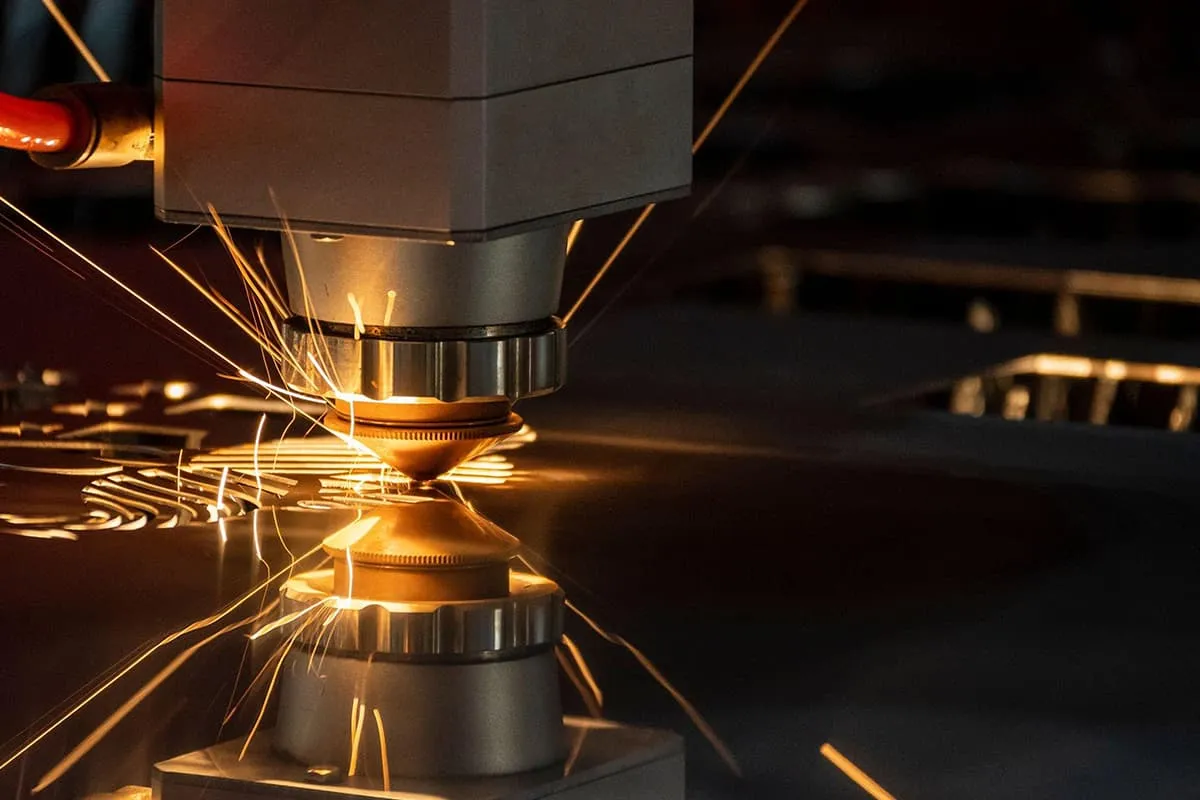

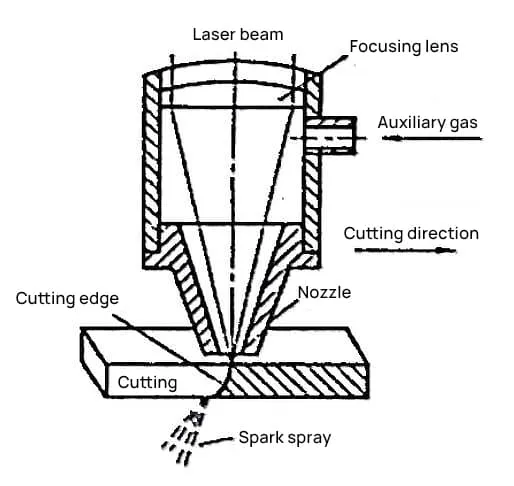

As depicted in Figure 1, the focused laser beam irradiates the workpiece, causing the material at the irradiated area to rapidly melt, vaporize, or reach its ignition point.

Concurrently, an auxiliary gas flow that’s coaxial with the laser beam blows away the melted or vaporized material. As the laser cutting head moves relative to the workpiece, a cut is formed. The blown away molten metal and slag create a spray of sparks beneath the cut.

Given the laser beam’s ability to focus on very small spots, and its concentrated heat source and high radiant illumination, laser cutting has several advantages over traditional oxyacetylene flame cutting and plasma arc cutting:

High-quality cuts

Mainly reflected in the following three aspects:

1) The cut is narrow, with a minimum of 0.1mm, typically ranging from 0.12 to 0.40mm.

2) The cut has good parallelism and perpendicularity, and the cutting surface is smooth (with a small surface roughness value). The general surface roughness value is only about Rz: =10~25μm range, and the edges have no burrs or slag, making it suitable for direct laser welding.

3) The heat-affected zone is narrow and thermal deformation is minimal. The general heat-affected zone ranges from 0.1 to 0.15mm, and when cutting thin plates, it can sometimes be as small as 30μm. Moreover, the cutting parameters are not significantly affected by changes in laser cutting parameters.

High cutting speed and high efficiency

For instance, using a 1200W CO2 laser, cutting a 2mm thick low carbon steel plate can reach a speed of 6m/min; cutting 5mm thick organic glass can reach 12m/min; and cutting 500 holes with a diameter of 10mm in a 1mm thick steel plate can be done in a minute. The fastest cutting speed can exceed 20m/min, which is unmatched by traditional cutting methods.

High processing flexibility

By programming, parts of any shape and size can be cut from the material; automatic programming can optimize the arrangement of parts to be cut and optimize the cutting path, thus reducing material loss and idle travel. If laser cutting is used instead of mold punching during the trial stage of car body parts production, it can save expensive molds, significantly reduce production costs, and shorten the production cycle.

Broad material adaptability

Laser processing is applicable to almost any metal and non-metal material, including those with high hardness, high melting point, brittle and sticky materials.

Classification and Mechanism of Laser Cutting

Depending on the cutting material and parameters, laser cutting can be categorized into the following four methods:

Vaporization Cutting

Under the irradiation of a high radiant illumination laser beam, the material is rapidly heated to the vaporization temperature, causing the material to vaporize or melt. Some of the vaporized material escapes from the surface of the workpiece at nearly the speed of sound, while some is blown away by the auxiliary gas stream from the bottom of the cut.

This cutting mechanism requires high radiant illumination of about 108W/cm2, which is 10 times the radiant illumination required for melt cutting. Materials that cannot melt, such as wood, plastic, ceramics, etc., are essentially cut in this form when laser cutting.

Melt Cutting

When the radiant illumination of the laser beam exceeds the melting value, the material undergoes melting at the laser-irradiated area. The melted material is expelled from the bottom of the cut by the action of the gas stream, forming a spray of sparks. The radiant illumination required for melt cutting is 1/10 that of vaporization cutting.

Reactive Melt Cutting

Reactive melt cutting is essentially melt cutting with oxygen as the auxiliary gas, hence it is also referred to as oxygen-assisted melt cutting. During oxygen-assisted melt cutting, the laser only needs to heat the cutting area to the material’s ignition temperature (lower than the melting point).

The oxygen, as the auxiliary gas, will have an intense combustion reaction with the material, releasing a large amount of heat. The resulting oxides and the molten metal surface are then blown away by the oxygen flow, forming a cut.

The heat of reaction for the oxidation of iron and titanium is as follows:

- Fe+1/2O2=FeO QR=260kJ/mol

- 3Fe+2O2=Fe3O4 QR=1120kJ/mol

- 2Fe+3/2O2=Fe2O3 QR=820kJ/mol

- Ti+1/2O2=TiO QR=543kJ/mol

The heat of the oxidation reaction is greater for titanium than for iron. When oxygen laser cuts steel, the exothermic reaction provides 60% of the cutting energy; when cutting titanium, it can provide up to 90% of the energy. Compared to melt cutting, oxygen-assisted melt cutting can significantly reduce the required laser power, effectively reducing cutting costs and improving cutting efficiency.

However, since the cut is oxidized, for crucial workpieces that cannot tolerate oxidation, reactive melt cutting is not suitable. Instead, inert gases or other non-oxidizing gases are used for melt cutting. For instance, titanium alloy plates in the aerospace industry and steel plates for car parts that are directly butt-welded after cutting.

Controlled Fracture Cutting

When brittle materials that are prone to thermal damage are heated by laser irradiation, they fracture rapidly and controllably. This process is referred to as controlled fracture cutting. The mechanism can be summarized as follows: the laser beam heats a small area of the brittle material, causing a thermal gradient and the resulting mechanical deformation, leading to material cracking.