I. Classification by Crystal Structure

Solids formed by atoms or atomic groups, ions or molecules arranged periodically in space according to certain rules are called crystals. The regular arrangement of atoms (ions or molecules) that form crystals in space is called the crystal structure.

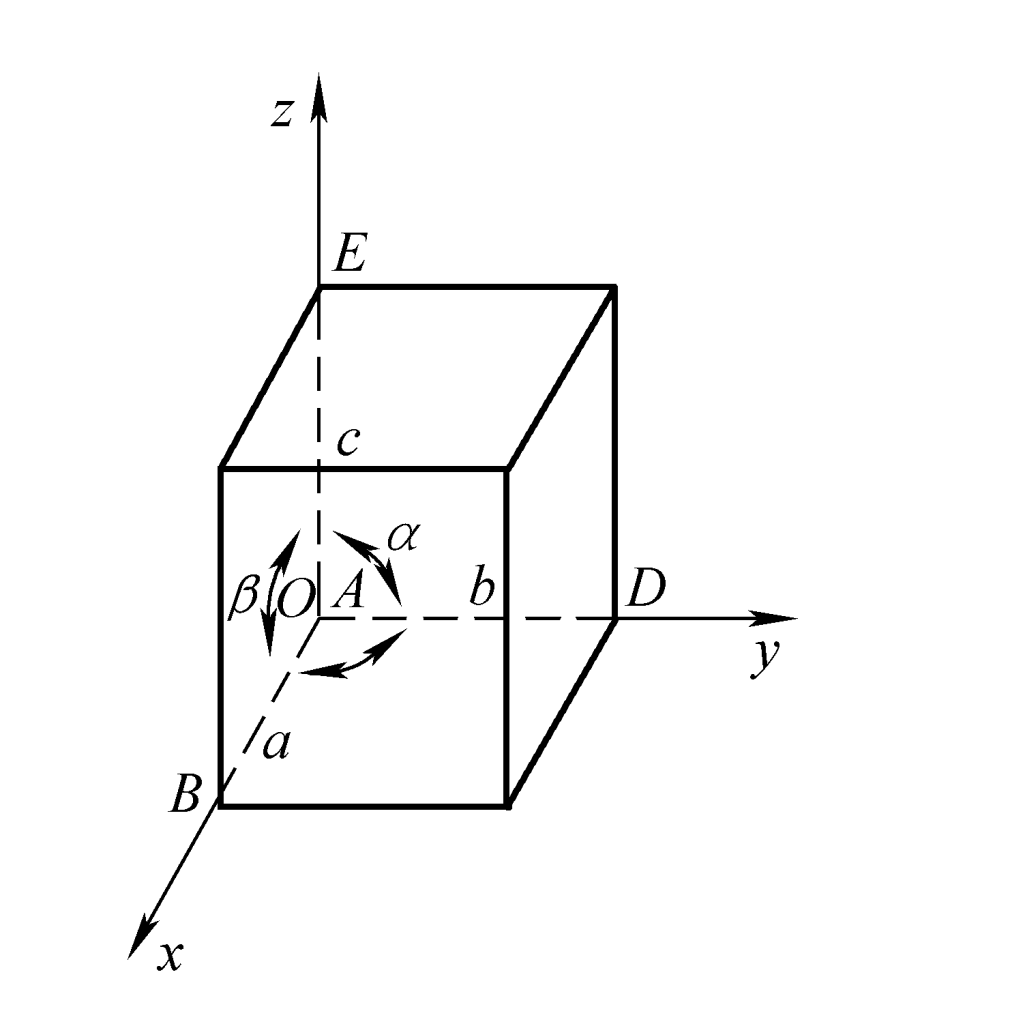

Due to the periodic regular arrangement of atoms in crystals, a minimum geometric unit that can fully reflect the characteristics of the crystal lattice can be selected from the lattice to analyze the pattern of atomic arrangement in the crystal. This smallest geometric unit is called a unit cell, as shown in Figure 1.

The geometric characteristics of the crystal lattice, such as size and shape, are described by parameters such as the edge lengths a, b, c of the unit cell and the angles α, β, γ between the edges. The edge lengths a, b, c of the unit cell are generally called lattice constants, and the lattice constants of metals are mostly 0.1~0.7nm.

According to the possible combinations of the above 6 parameters or based on the symmetry of the unit cell itself, crystal structures can be divided into 7 crystal systems, and each crystal system is further divided into several lattices, totaling 14 lattices.

Stamping materials can be divided into three types according to their crystal structure.

1. Face-centered cubic

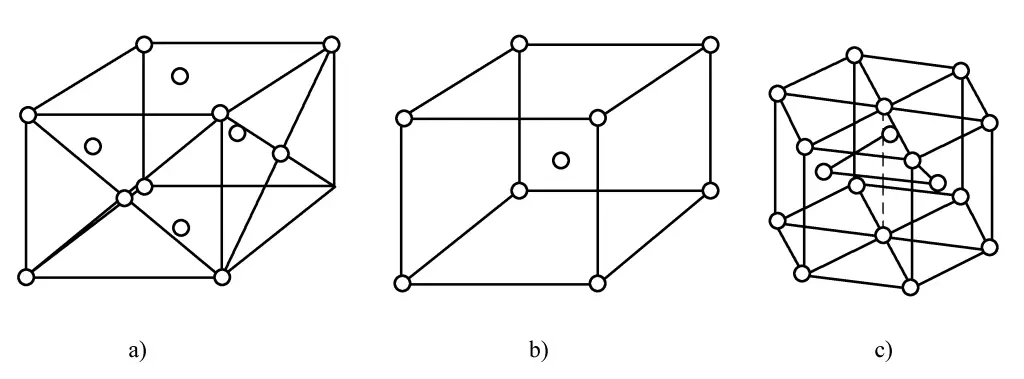

Metal atoms are distributed at the 8 corners of the cube and the centers of the 6 faces. The atoms at the center of the face are closely packed with the atoms at the 4 corners of that face, as shown in Figure 2a. The characteristics of the face-centered cubic unit cell are as follows.

a) Face-centered cubic structure

b) Body-centered cubic structure

c) Hexagonal close-packed structure

- Lattice constants: a=b=c, α=β=γ=90°.

- Number of atoms per unit cell: 1/8×8+1/2×6=4.

- Atomic radius: ratom =√2/4a.

- Packing density: 0.74 (74%).

- Tetrahedral interstitial radius: r4 =0.225ratom .

- Octahedral interstitial radius: r8 =0.414ratom .

- Coordination number: 12.

- Stamping materials with this crystal structure include γ-Fe, Al, Cu, β-Ti, Ag, Au.

2. Body-centered cubic

In the body-centered cubic lattice unit cell, 8 atoms are located at the corners of the cube, and one atom is at the center of the cube. The 8 atoms at the corners are closely packed with the center atom, as shown in Figure 2b. The characteristics of the body-centered cubic unit cell are as follows.

- Lattice constants: a=b=c, α=β=γ=90°.

- Number of atoms per unit cell: 1/8×8+1=2.

- Atomic radius: ratom =√3/4a

- Packing density: 0.68 (68%).

- Tetrahedral interstitial radius: r4 =0.29ratom .

- Octahedral interstitial radius: r8 =0.15ratom .

- Coordination number: 8.

- Stamping materials with body-centered cubic lattice include Ti, α-Fe.

3. Hexagonal close-packed

In the hexagonal close-packed lattice unit cell, 12 metal atoms are distributed at the 12 corners of the hexagonal prism, one atom is distributed at the center of each of the top and bottom faces, and 3 atoms are evenly distributed between the top and bottom faces, as shown in Figure 2c. The characteristics of the hexagonal close-packed unit cell are as follows.

- Lattice constants: expressed by the edge length a of the bottom regular hexagon and the distance c between the two base planes. The angle between two adjacent side faces is 120°, and the angle between the side face and the base plane is 90°.

- Number of atoms per unit cell: 1/6×12+1/2×2+3=6.

- Atomic radius: ratom =1/2a.

- Packing density: 0.74 (74%).

- Tetrahedral interstitial radius: r4 =0.225ratom .

- Octahedral interstitial radius: r8 =0.414ratom .

- Coordination number: 12.

- Stamping materials with hexagonal close-packed crystal structure include Mg, α-Ti, Zn.

II. Classification by Base Metal Type and Chemical Composition

Based on the color and properties of metals, they are divided into ferrous metals and non-ferrous metals.

1. Ferrous metals

Ferrous metals include iron, chromium, manganese, and their alloys. The main stamping material among ferrous metals is steel, which is classified into low carbon steel, ultra-low carbon steel, IF steel, low alloy steel, micro-alloy steel, medium alloy steel, and high alloy steel based on their carbon content and alloy content.

(1) Low-carbon Steel

Carbon steel with a carbon mass fraction below 0.25% is also called soft steel due to its low strength and hardness. It includes most ordinary carbon structural steels and some high-quality carbon structural steels, which are mostly used for engineering structural parts without heat treatment. The annealed structure of low carbon steel consists of ferrite and a small amount of pearlite, with low strength and hardness but good plasticity and toughness.

(2) Micro-carbon Steel

Low carbon aluminum-killed steel with a carbon mass fraction below 0.04% is called ultra-low carbon steel. It has been developed from traditional low carbon aluminum-killed steel by further reducing carbon content and purifying steel quality. The main grades include SPCE(N), St15, 03Al, etc.

(3) Interstitial-free Steel

IF steel refers to interstitial-free steel, sometimes also called ultra-low carbon steel.

In IF steel, due to the low C and N content, a certain amount of Ti and Nb is added to fix the C and N atoms in the steel into carbides, nitrides, or carbonitrides, thus eliminating interstitial atoms in the steel. The sum of carbon and nitrogen mass fractions should be less than 0.0005%, and advanced steelmaking processes have now reduced the carbon and nitrogen mass fractions in steel to below 0.0003%.

IF steel has excellent deep drawing properties, with elongation and r-value reaching 50% and 2.0 or above, respectively, and has been widely used in the automotive manufacturing industry.

(4) Low-alloy Steel

Alloy steel with a total mass fraction of alloying elements less than 3% is called low-alloy steel. Low-alloy steel is relative to carbon steel, and is based on carbon steel with one or several alloying elements intentionally added to improve one or several properties of the steel.

Compared to carbon steel, it has higher strength, better toughness, and sufficient plasticity, good formability and weldability, as well as corrosion resistance.

(5) Micro-alloy Steel

It usually refers to the addition of trace amounts of carbide and nitride-forming elements such as Nb, V, Ti to the composition of low carbon steel or low alloy steel, with the addition amount not exceeding 0.20% (mass fraction). After adding trace alloying elements, one or several properties of the steel are significantly improved.

(6) Medium-alloy Steel

Alloy steel with a total mass fraction of alloying elements between 3% and 10% is called medium alloy steel, such as silicon steel.

(7) High-alloy Steel

Alloy steel with a total mass fraction of alloying elements above 10% is called high-alloy steel, such as stainless steel, TWIP steel, etc.

2. Non-ferrous metals

In a narrow sense, non-ferrous metals refer to all metals except iron, manganese, and chromium. In a broad sense, non-ferrous metals also include non-ferrous alloys. Non-ferrous alloys are alloys composed of one non-ferrous metal as the base (usually with a mass fraction greater than 50%) and one or several other elements added.

(1) Aluminum alloys

Pure aluminum has a silvery-white metallic luster, is resistant to atmospheric corrosion, easy to form, has a face-centered cubic lattice, no allotropic transformation, and is non-magnetic. Alloys with aluminum as the base and other elements added are called aluminum alloys. The main alloying elements are copper, silicon, magnesium, zinc, and manganese, while secondary alloying elements include nickel, iron, titanium, chromium, lithium, etc.

Aluminum alloys have low density but relatively high strength, approaching or exceeding that of high-quality steel, and good plasticity, which can be processed into various profiles. They have excellent electrical conductivity, thermal conductivity, and corrosion resistance, and are widely used in industry, second only to steel in terms of usage. Common stamping aluminum alloys include:

1000 series, containing no other elements, also known as pure aluminum sheet, common grades include 1050, 1060, 1070.

2000 series, a heat-treatable strengthened aluminum alloy, with Cu and Mg as the main added elements, and its strengthening phase is CuAl 2 or CuMgAl 2 .

This series of alloys exhibits good forgeability, high strength, and some paint baking hardenability, but has poorer corrosion resistance compared to other series of aluminum alloys. It is mainly used in the aerospace field. Common grades include 2017, 2022, 2024, and 2036.

3000 series: Mn is its main alloying element, with a Mn mass fraction of 1% to 1.5%. It has good rust prevention function and is also known as anti-rust aluminum sheet. It is mainly used in automotive floor panels and home appliances. Common grades include 3003, 3004, 3005, 3105.

4000 series: Si is its main alloying element, with a Si mass fraction of 4.5% to 6%. It has heat-resistant and wear-resistant characteristics and is mainly used in construction and mechanical parts.

5000 series, Mg is the main alloying element, with a mass fraction of 3% to 5%. It has high tensile strength, high elongation, good corrosion resistance, and weldability. Common grades include 5005, 5052, 5083.

6000 series, the main alloying elements are Mg and Si, belonging to heat-treatable strengthened aluminum alloys. It has relatively high strength, good plasticity, and excellent corrosion resistance. Common grades include 6009, 6010, 6016, 6061, 6063, 6082.

7000 series, the main alloying element is Zn. It has high hardness and high strength, and is known as super-hard aluminum. Common grades include 7005, 7039, 7075.

(2) Magnesium alloys

Magnesium alloy is an alloy composed of magnesium as the base with other elements added. Its characteristics are: low density (about 1.8g/cm 3 ), high specific strength, large elastic modulus, good vibration damping, higher ability to withstand impact loads than aluminum alloys, and good resistance to organic substances and alkali corrosion.

The main alloying elements are aluminum, zinc, manganese, cerium, thorium, and small amounts of zirconium or cadmium. Currently, the most widely used are magnesium-aluminum alloys, followed by magnesium-manganese alloys and magnesium-zinc-zirconium alloys. Common magnesium alloy grades include AZ31, AZ40, AM50, AM60, etc.

(3) Titanium alloys

Pure titanium has low density, high specific strength, good plasticity, low-temperature toughness, and corrosion resistance. It has allotropes; below 882°C, it has a hexagonal close-packed crystal structure, called α-titanium; above 882°C, it has a body-centered cubic crystal structure, called β-titanium.

By utilizing the different characteristics of these two titanium structures and adding appropriate alloying elements, the phase transition temperature and phase content can be gradually changed to obtain titanium alloys with different structures. Titanium alloys have high strength and low density, good mechanical properties, and excellent toughness and corrosion resistance.

According to the annealed structure, titanium alloys are divided into three categories: α alloys, β alloys, and α+β alloys. In China, they are represented as TA, TB, and TC respectively, with TA0 to TA4 being pure titanium.

The main alloying element for α alloys is Al, along with Sn and B, represented by grades TA5 and TA7. The main alloying elements for β alloys are Mo, Cr, V, Al, represented by grades TB2, TB3, and TB4. The main alloying elements for α+β alloys are Al, V, Mo, Cr, represented by grade TC4.

(4) Copper alloys

Pure copper has a face-centered cubic crystal structure, no allotropic transformation, is non-magnetic, has excellent electrical and thermal conductivity, good corrosion resistance, and good plasticity. Alloys formed by adding one or several other elements to pure copper as the base are called copper alloys.

Common alloying elements are Zn, Sn, Al, Mn, Ni, Fe, Be, Ti, Zr, Cr, etc. Copper alloys improve strength while maintaining the characteristics of pure copper. Copper alloys are divided into three main categories: brass, bronze, and nickel silver.

Brass is a copper alloy with zinc as the main alloying element. Special brasses also contain Sn, Al, Mn, Ni, Fe, Pb, etc. Common grades include H59, H62, H68, H70, H80, HPb63-3, HSn62-1.

Nickel silver is a copper alloy with nickel as the main alloying element.

Bronze originally referred to copper-tin alloys, but later all copper alloys except brass and nickel silver were called bronze, often prefixed with the name of the first main alloying element. Common bronzes include tin bronze (QSn4-3, QSn6.5-0.4), aluminum bronze (QA₁5, QAl7), beryllium bronze (QBe2, QBe1.7), etc.

III. Classification by Production Process

1. Hot-rolled Plate

Hot-rolled plate is a type of quality carbon steel with a carbon mass fraction of 0.10% to 0.25%, belonging to low-carbon steel. According to its thickness specifications, it is divided into thin plates and medium-thick plates. Plates less than 4mm thick are called thin plates, those 4-20mm thick are called medium plates, and those 20-60mm thick are called thick plates.

Hot-rolled plates used for stamping production generally have a thickness ≤16mm, and for deep drawing generally ≤8mm. The surface quality of hot-rolled plates can be divided into two levels: FA and FB. The surface treatment of hot-rolled plates can adopt either pickled surface or non-pickled surface methods.

Hot-rolled steel plates do not have the microstructure of cold-rolled steel plates, so their stamping formability is not as good as cold-rolled steel plates. On the other hand, the thickness and performance variation of hot-rolled steel plates are large, which is also unfavorable for the stamping process. In addition to the chemical composition of the material, the size and arrangement of its grains also affect its strength and n-value.

Common non-pickled surface hot-rolled plates used for stamping are often made of quality carbon structural steel. Quality carbon structural steel is carbon steel with a carbon mass fraction less than 0.8%, containing less sulfur, phosphorus, and non-metallic inclusions than carbon structural steel, with relatively good mechanical properties.

Based on different carbon content, it can be divided into three categories: low-carbon steel (w c ≤0.25%), medium-carbon steel (w c =0.25%~0.6%), and high-carbon steel (w c >0.6%). Based on different manganese content, it is divided into two groups: normal manganese content (w mn 0.25%~0.8%) and higher manganese content (w mn 0.70%~1.20%), the latter having better mechanical properties and processing performance.

This type of plate is widely used in automotive, aviation industries and other sectors. The steel grades include rimmed steels 08F, 10F, 15F; killed steels 08, 08Al, 10, 15, 20, 25, 30, 35, 40, 45, 50.

Hot-rolled pickled plate is an intermediate product made from high-quality hot-rolled thin plates, processed through pickling units to remove oxide layers, edge trimming, and finishing. Its surface quality and usage requirements (mainly cold bending formability or stamping performance) are between hot-rolled plates and cold-rolled plates, making it an ideal substitute for some hot-rolled and cold-rolled plates. Common grades are SPHC, SPHD, SPHE.

2. Heat-treated plates

Heat treatment is applied to hot-rolled plates to obtain the desired structure and properties. Common heat treatment processes include normalizing, quenching and tempering (quenching + tempering, normalizing + tempering), high-temperature tempering, annealing, etc., with normalizing being the most common treatment.

3. Hot-rolled thermo-mechanically treated plates

Thermo-mechanical Treatment is a process that organically combines plastic deformation with heat treatment to achieve a comprehensive effect of deformation strengthening and phase transformation strengthening. Hot-rolled plates produced using thermo-mechanical treatment are called hot-rolled thermo-mechanically treated plates.

4. Cold-rolled plates

Cold-rolled plate coils are produced by rolling hot-rolled coils at room temperature below the recrystallization temperature, including plates and coils. Compared to hot-rolled plates, cold-rolled plates have better surface quality, higher dimensional accuracy, and can meet special performance and structural requirements such as electromagnetic properties and deep drawing properties.

Cold-rolled plates have relatively poor mechanical properties and high hardness, so they need to undergo annealing processes to eliminate work hardening and internal defects, and to impart some special performance characteristics such as deep drawing ability and magnetic conductivity.

Common grades of cold-rolled sheets for stamping include: Q195, Q215, Q235, Q275, 08, 08F, 10, 10F, SPCC, St1208A1, SPCD, SPCE, St13, St14, St15.

5. Coated plates

To prevent corrosion of steel plate products during use, surface-treated steel plates are produced after cold rolling and hot rolling by electroplating or hot-dip coating in corrosion-resistant metal solutions at 450-500°C. Since the surface coating is completed in metallurgical plants, these coils can be directly processed into products by users, so they are also called pre-coated coils.

Based on different base materials and coating processes, they are classified into hot-dip galvanized plates, hot-dip galvannealed plates, hot-dip galvalume plates, electrogalvanized plates, electro-galvannealed plates, electro-galvanized nickel alloy plates, tin plates, electro-chromium coated steel sheets, and color-coated steel plates.

(1) Hot-dip galvanized plates

Hot-dip galvanized plates are continuous hot-dip galvanized thin steel plates and strips with a thickness of 0.25-2.5mm. The steel strip first passes through a flame-heated preheating furnace to burn off surface oil residues and form an iron oxide film on the surface. It then enters a reduction annealing furnace containing H₂ and N₂ mixed gases, heated to 710-920°C, reducing the iron oxide film to sponge iron.

Then, the surface-activated and purified strip is cooled to a temperature slightly higher than the molten zinc and enters a zinc pot at 450-460°C, using air knives to control the zinc layer thickness. Finally, it undergoes chromate solution passivation treatment to improve white rust resistance.

Due to the zinc-iron alloy layer, it has superior corrosion resistance and wear resistance that electrogalvanized zinc cannot match. Common grades include Zn100-PT, Zn200-SC, Zn275-JY, SGCC, SGCD1, SGCD2, SGCD3, St01Z, St02Z, St03Z, St04Z, St05Z.

(2) Hot-dip galvannealed plates

After exiting the zinc bath furnace, the steel strip enters an alloying furnace for treatment, forming a zinc-iron alloy coating layer. The steel plate surface has no zinc spangle and is rough, with good coating adhesion and weldability, suitable for manufacturing automobiles, home appliances, etc.

(3) Hot-dip galvalume plates

A continuous molten coating process is used to coat zinc-aluminum alloy liquid onto the steel plate surface. It has good durability and heat resistance; compared to galvanized steel plates, it has a longer lifespan and better heat resistance; it is less likely to discolor at high temperatures, with similar processing and spray coating performance.

Based on the different aluminum content in the coating, there are two types: 55% aluminum-zinc plate (containing 55% Al, 43.4% Zn, and 1.6% Si by mass) and 5% aluminum-zinc plate (containing 5% Al and a small amount of rare earth elements, with the remainder being Zn).

(4) Electrogalvanized plates

Electrolysis is used to form a uniform, dense, and well-bonded zinc metal deposition layer on the steel plate surface. The zinc coating of electrogalvanized plates is thicker, with fine crystallization, uniform and pore-free, offering good corrosion resistance.

After chromic acid passivation, the zinc coating forms white, colorful, or military green appearances, which are aesthetically pleasing and have certain decorative properties. Common grades include SECC (original plate SPCC), SECD (original plate SPCD), SECE (original plate SPCE).

(5) Electro-galvannealed plates

Based on the mass fraction of iron in the coating, they are divided into high iron content and low iron content types. 0.4%-0.8% is considered low iron, while 3%-25% is high iron, with the former being more widely used than the latter.

The corrosion resistance of the zinc-iron alloy layer is 5-20 times that of pure zinc layer, with a hardness of 110-130HV, widely used in the automotive and home appliance manufacturing industries.

(6) Electro-galvanized nickel alloy

The mass fraction of zinc is 80%-90%, and nickel is 10%-20%. The salt spray test effect can reach over 2000h, which is 5-10 times that of ordinary electrogalvanized zinc.

(7) Tin-plated plates

The English abbreviation is SPTE, referring to cold-rolled low-carbon thin steel plates or strips coated with commercially pure tin on both sides, usually with a thickness ≤0.6mm. Tin mainly serves to prevent corrosion and rusting. It has certain strength and hardness, good formability, easy weldability, bright surface, and can be printed with images to beautify products.

It is mainly used in the food canning industry, and secondarily used for packaging materials in chemical paints, oils, pharmaceuticals, etc. Tin-plated plates are divided into hot-dip tin plates and electrolytic tin plates based on production processes.

(8) Electrolytic Chromium Coated Steel (ECCS)

A product formed by cathodic reduction of cold-rolled thin steel plates in a chromic acid solution, creating an extremely thin layer of metallic chromium and hydrated chromium oxide film on the steel plate surface. Due to the strong passivation ability of the metallic chromium layer, chromium-plated plates have high chemical stability and corrosion resistance.

It has a low price, strong paint adhesion (3-4 times higher than tin-plated plates), good heat resistance allowing high-temperature baking to improve printing production efficiency, and good sulfur resistance to prevent sulfide stains. It can be used for fish, meat, and some sulfur-containing canned foods without easily blackening. However, it is inferior to tin-plated plates in terms of corrosion resistance and appearance.

(9) Color-coated steel plates

Color-coated steel plates are produced on continuous production lines using cold-rolled steel strips or galvanized steel strips (electrogalvanized and hot-dip galvanized) as base plates. After surface pretreatment (degreasing and chemical treatment), one or more layers of liquid coating are applied using roller coating methods, followed by baking and cooling.

Since the coating can have various colors, coated steel plates are commonly referred to as color-coated steel plates. Depending on the base plate and coating, there are several main types.

1) Cold-rolled base color-coated steel plates.

Color-coated plates produced from cold-rolled base plates have a smooth and beautiful appearance and retain the processing properties of cold-rolled plates. However, any small scratch on the surface coating will expose the cold-rolled base plate to air, causing red rust to form quickly at the scratch. Therefore, these products can only be used for low-requirement temporary isolation measures and indoor applications.

2) Hot-dip galvanized color-coated steel plates.

Hot-dip galvanized color-coated steel plates are products obtained by coating organic paints on hot-dip galvanized steel plates. In addition to the protective effect of zinc, the organic coating on the surface also provides isolation protection and prevents rusting, resulting in a longer service life compared to hot-dip galvanized plates.

3) Hot-dip galvalume color-coated steel plates.

These use hot-dip galvalume steel plates as the base for color coating (55% aluminum-zinc plates and 5% aluminum-zinc plates).

4) Electrogalvanized color-coated steel plates.

Electrogalvanized color-coated steel plates are products obtained by coating organic paints on electrogalvanized plates and baking. Due to the thin zinc layer of electrogalvanized plates, these products are not suitable for outdoor use in walls, roofs, etc.

However, because of their beautiful appearance and excellent processing properties, they are mainly used in home appliances, audio equipment, furniture, and interior decoration.

5) Printed steel sheets.

Printed steel sheets, also known as printed steel plates, are produced by first applying a layer of oil on hot-dip galvanized or electrogalvanized steel plates, baking, then printing ink patterns using photogravure or lithographic printing methods, and finally applying a clear coat and baking. They are mainly used for decorative items.

6) Laminated steel sheets.

A layer of adhesive is first applied and baked on the base material, then PVC or PVF film is laminated with the base material. This is considered the highest grade of color-coated products, offering both aesthetics and durability.

7) Film-embossed sheets.

PVC sol is applied to galvanized plates, baked, and then patterns are embossed on the film using embossing rollers. These are used in buildings, interior decoration, and furniture.

8) Metal-embossed sheets.

The metal base plate is embossed with concave and convex patterns, providing an excellent three-dimensional effect. These are used for interior decoration.

IV. Classification by application

1. Automotive plates

The components that make up a vehicle body are generally divided into panel components, structural components, running gear components, and reinforcement components. Automotive plates include body structural plates, body cover plates (inner body panels, outer body panels), automotive chassis plates, and wheel rim plates. These components correspond to different application requirements and have different properties.

From the perspective of production process characteristics, steel plates can be divided into hot-rolled steel plates, cold-rolled steel plates, and coated steel plates; from the strength perspective, they can be classified into ordinary steel plates (soft steel plates), high-strength low-alloy steel plates (HSLA), ordinary high-strength steel plates (high-strength IF steel, BH steel, RP steel, and IS steel, etc.), and advanced high-strength steel plates (AHSS), etc.

2. Household appliance plates

Mainly used for the exterior panels of household appliances (such as refrigerators, washing machines, air conditioners, computers, etc.), primarily using PCM, ordinary cold-rolled plates, galvanized plates, and patterned plates.

3. Aviation plates

Mainly refers to materials used in aircraft, with the most important being the airframe structural materials. Due to the different stress conditions on the upper and lower wing surfaces, the wing skin uses ultra-hard aluminum with good compressive properties and hard aluminum with good tensile and fatigue properties respectively; the fuselage uses hard aluminum with high tensile strength and fatigue resistance as the skin material.

The fuselage frames generally use ultra-hard aluminum, while reinforced frames that bear greater loads use high-strength structural steel or titanium alloys.

4. Ship hull structural steel

Ship hull structural steel, also known as ship plate steel, mainly refers to plate materials used for manufacturing hulls, decks, etc., of ocean-going, coastal, and inland waterway vessels. Steel grades include general strength ship plates (grades A to E4), high-strength ship plates (12 grades from AH32 to EH40), and ultra-high-strength ship hull steel (AH42 to FH69).

5. Boiler steel plates

Boiler steel plates are mainly hot-rolled medium and thick plate materials used to manufacture superheaters, main steam pipes, and boiler furnace heating surfaces. The main materials are high-quality structural steel and low-alloy heat-resistant steel.

As boiler steel plates work under medium temperature (around 350°C) and high-pressure conditions, in addition to withstanding high pressure, they are also subject to impact, fatigue loads, and corrosion from water and gas. The main performance requirements for boiler steel plates include good welding and cold bending properties, certain high-temperature strength, and resistance to alkaline corrosion and oxidation. Common grades include Q245R, Q345R, and 15CrMoR.

6. Pressure vessel steel

Pressure vessel steel is used to manufacture pressure vessels or other similar equipment for petroleum, chemical, gas separation, and gas storage and transportation industries. It includes carbon steel, carbon manganese steel, microalloyed steel, low-alloy high-strength steel, and low-temperature steel. The main steel grades are Q245R, Q345R, and Q370R.

V. Classification by performance characteristics

1. Drawing steel

Carbon steel with carbon content ≤0.20% and yield strength below 275MPa. It has excellent plasticity and superior deep drawing characteristics, so it is widely used in products with complex structures that require deep drawing.

It is divided into general commercial use (CQ grade, such as 08Al, St12, SPCC, etc.), drawing use (DQ grade, such as 08Al, St13, SPCD, etc.), deep drawing use (DDQ grade, such as 08Al, St14, SPCE, etc.), extra deep drawing use (SDDQ grade, such as St15), and ultra-deep drawing use (EDDQ, such as St16).

2. Conventional High Strength Steel (CHSS)

Steel with tensile strength of 300-600MPa, mainly including carbon manganese (C-Mn) steel, bake hardening steel (BH), isotropic steel (IS), high-strength interstitial-free steel (HSS-IF), and high-strength low-alloy steel (HSLA).

(1) High-strength interstitial-free steel (HSS-IF)

High-strength interstitial-free steel belongs to solid solution strengthened steel, mainly by adding solid solution strengthening elements such as P, Mn, Si to interstitial-free steel to increase strength. Its r-value can increase to 2.0, and tensile strength can reach 400MPa. High-strength interstitial-free steel with added Ti, Nb, and B can reach tensile strengths of 400-450MPa.

Due to its combination of high strength and deep drawing performance, high-strength interstitial-free steel can be processed into complex-shaped parts and improve the dent resistance of automobiles while reducing vehicle weight, meeting the requirements of automobile safety, weight reduction, energy conservation, and environmental protection.

(2) Isotropic Steel (IS)

Isotropic steel is a type of steel with a specified plastic strain ratio (r-value). Due to its isotropic properties, this steel has good deep drawing formability and is suitable for the manufacture of automotive exterior panels.

(3) Bake Hardening Steel (BH)

Bake hardening steel is a type of cold-rolled steel sheet that combines the deep drawing properties of drawing steel with the solid solution strengthening mechanism of alloying elements P (or Mn), and obtains excellent comprehensive properties such as high strength, deep drawing ability, and good dent resistance through the strain hardening mechanism of bake hardening.

Currently, four main types of BH steel sheets have been developed: nitrided steel sheets, dual-phase steel sheets, phosphorus-aluminum killed bake hardening steel sheets, and extra-low carbon bake hardening steel sheets (ELC-BH steel sheets).

BH steel sheets have good press forming performance and plasticity, high dent resistance and strength, suitable for automotive parts, especially for press forming of automotive body exterior panels, and have been widely used in the automotive manufacturing industry.

(4) High Strength Low Alloy Steel (HSLA)

High-strength low-alloy steel is developed based on carbon structural steel with carbon content ≤0.20%, with the addition of small amounts of alloying elements, and has a yield strength higher than 275MPa.

In addition to containing certain amounts of basic elements such as silicon (Si) or manganese (Mn), this type of steel also contains trace amounts of other elements such as vanadium (V), niobium (Nb), titanium (Ti), aluminum (Al), molybdenum (Mo), nitrogen (N), and rare earth elements (RE).

Compared to carbon structural steel, it has advantages such as high strength, good comprehensive performance, long service life, wide application range, and economic efficiency. It is widely used in bridges, ships, boilers, vehicles, and important building structures. Grades include Q345 (A, B, C, D, E), Q390 (A, B, C, D, E), Q420 (A, B, C, D, E), Q460 (C, D, E), etc.

3. Advanced High Strength Steel (AHSS)

Advanced high-strength steel, also known as high-grade high-strength steel. It mainly includes dual-phase steel (DP), transformation-induced plasticity steel (TRIP), complex phase steel (CP), martensitic steel (M), hot-formed steel (HF), and twinning-induced plasticity steel (TWIP).

AHSS has a tensile strength of 500-1500MPa and excellent energy absorption properties. It plays a very important role in automotive weight reduction and improving safety, and has been widely used in the automotive industry, mainly for manufacturing automotive structural parts, safety components, and reinforcement parts.

(1) Dual Phase Steel (DP)

Obtained from low-carbon steel or low-carbon microalloyed steel through two-phase region heat treatment or controlled rolling and cooling, its microstructure mainly consists of ferrite + martensite or ferrite + bainite. The strengthening phase gives the material high tensile strength, while the ferrite matrix provides good plasticity and toughness. The main characteristic of dual-phase steel in terms of chemical composition is low carbon and low alloy content.

The main alloying elements are Si and Mn. Additionally, depending on the production process and usage requirements, appropriate amounts of Cr, Mo, V, and Nb elements can be added, forming dual-phase steel composition series mainly based on C-Si-Mn, C-Mn-Mo, C-Si-Mn-Cr-V, and C-Si-Mn-Cr-Mo systems.

(2) Transformation Induced Plasticity Steel (TRIP)

Transformation-induced plasticity steel is a steel with multiple phase structures. These phases are usually ferrite, bainite, retained austenite, and martensite.

During deformation, the transformation of stable retained austenite to martensite induces transformation strengthening and increased plasticity. For this reason, the retained austenite must have sufficient stability to achieve progressive transformation, strengthening the matrix on one hand and improving uniform elongation on the other, to achieve the goal of simultaneous improvement in strength and plasticity.

The properties of TRIP steel are: yield strength 340-860MPa, tensile strength 610-1080MPa, elongation 22%-37%. TRIP steel is mainly used to manufacture automotive fenders, chassis components, wheel rims, and door impact beams.

(3) Complex Phases Steel (CP)

The structure is similar to TRIP steel, with the main structure being fine ferrite and a high proportion of hardening phases (martensite, bainite), containing elements such as Nb and Ti. Through the combined effect of martensite, bainite, and precipitation strengthening, CP steel can reach strengths of 800-1000MPa, with relatively high impact energy absorption and hole expansion performance, making it particularly suitable for manufacturing automotive safety parts such as door anti-collision bars, bumpers, and B-pillars.

(4) Martensitic Steel (MART)

Martensitic steel is produced by rapidly quenching high-temperature austenite structure to form lath martensite structure, which can be achieved through hot rolling, cold rolling, continuous annealing, or post-forming annealing. Its maximum strength can reach 1600MPa, making it the highest strength grade among commercially available high-strength steel sheets. Due to formability limitations, it can only be used to press simple-shaped parts and is mainly used in the manufacture of parts with low forming requirements, such as door anti-collision bars.

(5) Twinning Induced Plasticity Steel (TWIP)

Twinning-induced plasticity steel is a low stacking fault energy austenitic steel. When used without external load, its structure cooled to room temperature is stable retained austenite. However, under external load, mechanical twinning is produced due to strain induction, resulting in large uniform elongation without necking, showing excellent mechanical properties, high strain hardening rate, high plasticity, and strength.

Twinning is the main mechanism affecting its plastic deformation, and its mechanical properties mainly depend on the stacking fault energy. TWIP steel has extremely high plasticity indices (elongation after fracture of 60%-80%), high strength (tensile strength of 600-800MPa), and a high strain hardening rate. Its impact energy absorption is twice that of existing high-strength steels.

In addition, TWIP steel also has high energy absorption capacity and no low-temperature ductile-to-brittle transition temperature. The composition of TWIP steel typically consists mainly of Fe, with 15%-30% Mn by mass, 2%-4% Al and Si by mass, and may also include small amounts of Ni, V, Mo, Cu, Ti, Nb, etc.

4. Weathering Steel

Weathering steel is a type of low-alloy high-strength steel. By adding small amounts of alloying elements such as Cu, P, Cr, and Ni to the steel, a dense, 50-100μm thick amorphous spinel-type oxide layer with good adhesion to the base metal is formed between the rust layer and the substrate. This layer prevents oxygen and water from the atmosphere from penetrating into the steel substrate, protecting the base metal under the rust layer and slowing down the progression of corrosion into the steel material, thus greatly improving the atmospheric corrosion resistance of the steel material.

Weathering steel is widely used in the manufacture of various metal structural components for locomotives, vehicles, buildings, etc. Common grades include Corten A, Corten B, 10CrNiCuP, 09CuPTiRE, SPA-H, etc.

5. Stainless Steel

Stainless steel refers to steel that is resistant to corrosion from weak corrosive media such as air, steam, water, and chemical corrosive media like acids, alkalis, and salts. It is also known as stainless acid-resistant steel. Stainless steel is usually classified by its base structure into: austenitic stainless steel, ferritic stainless steel, austenitic-ferritic duplex stainless steel, and martensitic stainless steel. The first three types are mainly used as stamping materials.

(1) Austenitic Stainless Steel

Austenitic stainless steel refers to stainless steel with an austenitic structure at room temperature. When the mass fractions of elements in the steel are approximately 18% Cr, 8%-10% Ni, and about 0.1% C, it has a stable austenitic structure.

Austenitic stainless steel is non-magnetic and has high toughness and plasticity, but its strength is relatively low. It cannot be strengthened through phase transformation and can only be strengthened through cold working.

(2) Ferritic Stainless Steel

Ferritic stainless steel refers to stainless steel that is primarily ferritic in structure during use. The mass fraction of Cr is 11%-30%, and it has a body-centered cubic crystal structure.

This type of steel generally does not contain Ni, and sometimes contains small amounts of Mo, Ti, Nb, and other elements. This type of steel has characteristics such as high thermal conductivity, low expansion coefficient, good oxidation resistance, and excellent stress corrosion resistance. It is often used to manufacture parts resistant to atmospheric, steam, water, and oxidizing acid corrosion.

Typical varieties include AISI409(L), 06Cr13Al, 00Cr12Ni, 430 (10Cr17), 444 (019Cr19Mo2NbTi), 44629(000Cr26Mol), 447J1(000Cr30Mo2), etc.

(3) Duplex Stainless Steel

In its solid solution structure, ferritic and austenitic phases each account for about half, and even the minor phase should reach a volume fraction of 30%. With low C content, the mass fraction of Cr is 18%-28%, and the mass fraction of Ni is 3%-10%. Some steels also contain alloying elements such as Mo, Cu, Nb, Ti, and N.

This type of steel combines the characteristics of austenitic and ferritic stainless steels. Compared to ferritic stainless steel, it has higher plasticity and toughness, no room temperature brittleness, and significantly improved intergranular corrosion resistance and weldability, while retaining the 475°C embrittlement, high thermal conductivity, and superplasticity of ferritic stainless steel.

Compared to austenitic stainless steel, it has higher strength and significantly improved resistance to intergranular corrosion and chloride stress corrosion. Duplex stainless steel has excellent pitting resistance and is also a type of nickel-saving stainless steel.

6. Silicon Steel

Silicon steel is a silicon-iron alloy with a silicon mass fraction of about 3%. It is an important soft magnetic alloy indispensable in the electric power, electronics, and military industries, mainly used as core material for various motors, generators, and transformers.

It is divided into hot-rolled silicon steel sheet (used in generator manufacturing), cold-rolled non-oriented silicon steel sheet (used in generator manufacturing), cold-rolled oriented silicon steel sheet (used in transformer manufacturing), and high-magnetic induction cold-rolled oriented silicon steel sheet (used in the manufacture of various transformers, chokes, and other electromagnetic components in the telecommunications and instrument industries).

VI. Classification by Processing and Forming Technology Characteristics

1. Laser Tailored Blanks

Tailored blanks are made by laser welding the edges of several steel sheets with different materials, thicknesses, and coatings into a single integral sheet to meet different material performance requirements for parts. After processes such as stamping, they become automotive components.

It mainly solves the problem that cold rolling cannot produce extra-wide plates and plates of unequal thickness. Currently, materials used for laser tailored welding include low carbon steel, low alloy steel, high-strength steel, aluminum alloy, and magnesium alloy. Stamped parts are mainly used to manufacture automotive components such as door inner panels, floor panels, and pillars.

2. Hydroformed Plates (Tubes)

Metal sheet hydroforming technology refers to a process that uses liquid medium instead of concave or convex molds, relying on the pressure of the liquid medium to form the sheet. This process can not only form workpieces with complex shapes but also produces parts with high precision, good surface quality, and lower processing costs compared to conventional processes.

3. Composite Sandwich Panels

A new type of composite material with color-coated steel sheets, stainless steel sheets, etc., as the face layers, and lightweight, fire-resistant, flame-retardant materials such as glass fiber wool, rock wool, polystyrene as the core layer. It has advantages such as fire resistance, thermal insulation, heat insulation, sound insulation, vibration isolation, and light weight, and is widely used in aerospace, shipbuilding, vehicles, and industrial and civil construction.

4. Hot Formed Steel Plate

Special high-strength boron alloy steel is heated to austenitize, then the red-hot sheet is sent into a mold with a cooling system for press forming, while simultaneously undergoing rapid and uniform cooling quenching. The steel plate structure changes from austenite to martensite, resulting in ultra-high strength steel plate. It can be widely used in the manufacture of automotive components such as front and rear bumpers, A-pillars, B-pillars, C-pillars, door inner panels, and door impact beams.

5. Superplastic Materials

Superplasticity refers to the ability of certain metals or alloys to elongate more than 100% under specific conditions, namely at low strain rates (ε=10⁻⁴~10⁻² s⁻¹), at a certain deformation temperature (about half the thermodynamic melting temperature), and with stable and fine grain sizes (0.5~5μm).

For example, steel with an elongation exceeding 500%, pure titanium exceeding 300%, aluminum-zinc alloy exceeding 1000%, materials with such properties are called superplastic materials. Currently, commonly used superplastic materials mainly include aluminum alloys, magnesium alloys, titanium alloys, low carbon steel, stainless steel, etc.