Key takeaways:

- The laser cutting industry is characterized by rapid technological advancements and a crowded marketplace, with top manufacturers like Trumpf, Hanslaser, and HGTECH distinguishing themselves through innovation, quality, and comprehensive solutions tailored to various industries, from IT manufacturing to aerospace.

- These leading companies not only offer advanced machinery but also emphasize strong after-sales service networks, strategic partnerships with research institutions, and a commitment to R&D, ensuring their products and services integrate seamlessly with customers’ manufacturing processes and contribute significantly to the reindustrialization trend.

- Bystronic exemplifies the industry’s move towards digitalization by focusing on the automation of material and data flows in sheet metal processing, indicating a broader shift in the sector towards interconnected, smart manufacturing environments that enhance efficiency and sustainability.

Laser cutting is a technique that uses a laser to cut materials. The basic principle of laser cutting typically involves directing the output of a high-power laser through optical devices. Laser optics and CNC (computer numerical control) are used to direct the material or the generated laser beam. The laser cutting machine first projects the laser beam onto the surface of the workpiece, melting it, and finally uses the energy released by the laser to evaporate specific areas of the workpiece.

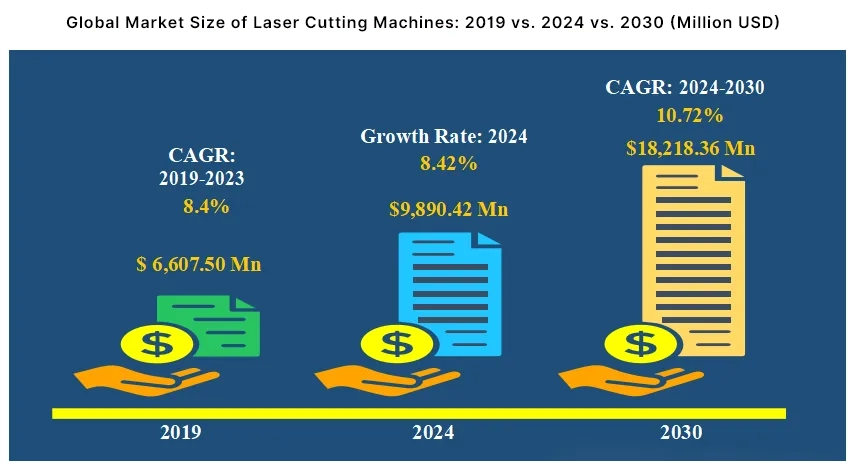

Global Market Size of Laser Cutting Machines

Research indicates that in 2023, the global laser cutting machine market size is approximately $9,122.58 million, and it is expected to reach $18,218.36 million by 2030, with a compound annual growth rate (CAGR) of 10.72% from 2024 to 2030.

In 2023, China accounted for 38.75% of the global market share, while the United States held 16.27%. Over the next six years, China’s market is projected to grow at a CAGR of 12.44%, reaching a market size of $7,776.01 million by 2030. During the same period, the U.S. market is expected to grow at a CAGR of approximately 9.54%.

On the production side, China is currently the largest producer of laser cutting machines globally, accounting for about 56.28% of production, followed by Europe with approximately 15.44% of production. The leading global laser cutting machine manufacturers include Trumpf, Bystronic, Mazak, Han’s Laser, Bond Laser, and Amada, with the top six companies holding around 36.23% of the global market share.

In terms of power range, laser cutting equipment under 1,000W is mainly used for precision cutting in the semiconductor and 3C electronics fields. Laser cutting equipment in the 1,000-6,000W range is commonly used for cutting thin and medium-thick sheets in the hardware, home appliance, and chassis cabinet industries. Equipment over 6,000W is primarily utilized for cutting thick plates in the aerospace, rail transportation, and oil pipeline sectors.

Top Laser Cutting Machine Manufacturers

As a professional in the industry, I can attest that laser cutting technology has seen significant advancements in the past few years. Consequently, the market has become populated with a plethora of companies specializing in manufacturing state-of-the-art laser cutting machines. In order to help potential buyers navigate this crowded landscape, I’ve decided to shed some light on the top laser cutting machine manufacturers.

These manufacturers set themselves apart through a combination of factors, including a reputation for quality, precision, and customer satisfaction, as well as their history of innovation and groundbreaking designs. As I delve into this topic, I will highlight the unique attributes and competitive advantages that make these companies the top choices for both hobbyists and professionals alike.

It’s important to note that the ideal laser cutting machine will vary depending on each individual’s specific needs and requirements. As I discuss the top manufacturers, I encourage readers to carefully assess your own demands and expectations to identify the ideal solution for your projects. In doing so, you can ensure you are investing in a quality product that will deliver consistent results and unlock your creativity.

1. Trumpf

Country: Germany

Founded: 1923

About the company:

Germany Trumpf is an innovative high-tech company, which is divided into three parts: machine tools, laser technology and electronics.

Since its establishment in 1923, Trumpf has developed into a leader in the international market and technology in all its business areas.

Trumpf (China) Co., Ltd. is a wholly-owned subsidiary of Trumpf Group.

Trumpf’s subsidiary in China was established in 2000.

At present, Trumpf has more than 500 employees in China.

Provide customers with innovative quality products and solutions to their problems;

These solutions involve sheet metal processing, laser production process, power supply application, etc.

Headquartered in Taicang, Trumpf China has many branches and representative offices in different cities, which have developed rapidly in recent years.

In order to support the long-term strategic development in China, Trumpf China has invested more than 20 million euros in the past decade, and further investment projects are also planned.

2. Bystronic

Country: Switzerland

Founded: 1964

About the company:

Bystronic is a world leading technology company in the field of sheet metal processing.

Bystronicl’s high-quality solutions help you achieve an efficient and sustainable future.

Its focus is on the automation of the entire material flow and data flow in the cutting and bending process chain.

The intelligent networking of Bystronic’s laser cutting system and bending machine with innovative automation, software and service solutions is the key to realizing comprehensive digitalization in the sheet metal industry.

Bystronicl is headquartered in Niederonz, Switzerland.

Other R&D and production bases are located in Sulgen (Switzerland), Gotha (Germany), Cazzago San Martino and San Guiliano Milanese (Italy), Tianjin and Shenzhen (China) and Hoffman Estates (United States).

It has opened its own sales and service companies in more than 30 countries, and has set up representative offices in more countries.

Bystronic has more than 3000 employees in more than 40 bases around the world, with net sales of 801 million Swiss francs in 2020.

Since 2021, Bystronic AG has been listed on the Swiss Stock Exchange (SIX: BYS).

3. Mazak

Country: Japan

Founded: 1919

About the company:

Yamazaki Mazak is an enterprise in the Japanese machine tool industry that started overseas production earlier.

Since the establishment of the American factory in 1974, many production bases have been established in Britain, Singapore and China.

It is one of the few machine tool manufacturers that has established a global production system.

Since its establishment, Mazak has promoted globalization by actively expanding production and support bases, and continued to make contributions to customer development and manufacturing industry around the world by providing high-quality products and technologies.

It is Mazak’s mission as a machine tool manufacturer to contribute to the society and make people’s lives more colorful.

At present, the manufacturing industry is facing various problems such as labor shortage.

Mazak will use advanced technologies such as loT and AI to accelerate the development of new products and services, and provide customers with solutions to promote automation and more intelligent production sites.

Yamazaki Mazak (China) Co., Ltd. is a wholly-owned subsidiary of Yamazaki Mazak Co., Ltd. in China.

Fully responsible for Mazak’s R&D, production, sales and services in the Chinese market.

Through long-term investment, a comprehensive customer support system covering production, sales, engineering technology, after-sales service and spare parts support has been established, mainly including a comprehensive after-sales service facility integrating spare parts, training and service – Yamazaki Mazak China Spare Parts Center;

Two advanced intelligent network chemical plants – Ningxia Xiaobairen Machine Tool Co., Ltd. (2000) and Yamazaki Mazak Machine Tool (Liaoning) Co., Ltd. (2013); Shanghai (2008), Guangzhou and Dalian (2010) three technical centers integrating exhibition, spare parts, training and technical support;

4 technical service centers in Beijing, Chongqing, Suzhou and Hangzhou and sales outlets all over the country.

4. Hanslaser

Country: China

Founded: 1996

About the company:

HansLaser Technology Industry Group Co., Ltd. provides customers at home and abroad with a complete set of laser processing solutions and related supporting facilities.

Its main products include laser marking machine series, laser welding machine series, laser cutting machine series, new energy laser welding equipment, industrial robots and other series of more than 200 kinds of industrial laser equipment and intelligent equipment solutions.

The company’s products cover many industries, such as IT manufacturing, new energy power battery manufacturing, electronic circuit, instrument and meter, computer manufacturing, mobile phone communication, household appliances, kitchen and bathroom, auto parts, precision equipment, building materials, hardware tools, clothing, urban lighting, jewelry, craft gifts, food and medical packaging.

HansLaser has a perfect sales and after-sales service network in the industry in China, covering the whole country.

It has dozens of branches and agents overseas, and has established a special industry service department to provide customers in different industries with laser processing process analysis and comprehensive laser application solutions, so that laser technology can seamlessly connect with manufacturing processes in various industries.

At present, HansLaser has a research and development team of thousands of people, and many domestic and foreign patents and computer software copyrights.

The company has established strategic cooperation relations with many famous research institutions in China, and jointly established relevant laboratories, talent training bases and other projects.

In terms of production, in accordance with the ISO9001 quality control system and ISO14001 environmental management system, HansLaser strictly controls the incoming materials, processing, complete machines and shipping of products to ensure product performance and quality, and several series of products have obtained the EU CE certification.

5. Bodor

Country: China

Founded: 2008

About the company:

Bodor Laser’s headquarters is located in Jinan, the capital city of Shandong province, China. The company boasts a substantial production base covering 60,000 square meters and employs over 3,000 people globally.

Bodor Laser manufactures a wide range of laser machines, including CO2 and fiber laser machines used for cutting, engraving, and marking various materials. Their flagship products include high-power fiber laser cutting machines and handheld laser welding machines.

Bodor Laser is recognized for its technological advancements and innovation in the laser industry. The company has introduced several groundbreaking products, including the world’s first 22,000W laser cutting machine and other high-power models up to 40,000W. They hold over 700 patents and have received more than 40 awards for their contributions to the field.

The company adheres to international quality standards such as CE, FDA, SGS, and ISO9001. They have a robust quality control system that includes the use of laser interferometers, laser power meters, and optical microscopes to ensure the precision and reliability of their products.

Bodor Laser has a dominant presence both domestically and internationally, with 70% of its turnover coming from exports. The company serves customers in over 150 countries and regions, with a strong market network and 150+ overseas service engineers providing immediate on-site support.

In April 2019, Bodor Laser established its first subsidiary in the United States, BODORLASER INC., located in Chicago, Illinois. This subsidiary aims to provide efficient and reliable cutting solutions to North American customers.

Bodor Laser offers extensive customer support, including a three-year warranty, free maintenance for three years, and 24/7 online service. They also provide consumable parts at agency prices and have 30 overseas spare part centers to ensure timely replacements.

The company provides professional laser cutting consultation both online and offline. Their senior engineers offer tailored product solutions based on customer requirements, ensuring a high level of customer satisfaction.

Bodor Laser is committed to the well-being of its staff and society. The company aims to gain global recognition with its “Made-in-China” products and to transform human life through advanced laser technology.In summary, Bodor Laser stands out as a leader in the laser cutting industry, known for its innovative products, stringent quality control, and exceptional customer service. The company’s global reach and commitment to technological advancement position it as a key player in the market.

6. AMADA

Country: Japan

Founded: 1946

About the company:

AMADA., LTD is a large multinational company specializing in the production of sheet metal processing machinery.

From the aspects of market size, product structure, product technical performance and comprehensive management system, it has gradually formed a group listed company integrating product development, design, manufacturing, education and training, and after-sales service, and has a marketing network.

The company has 83 branches in all continents of the world, and its products are marketed in more than 100 countries and regions around the world.

It produces sheet metal processing machinery with many varieties, good performance and advanced technology, and is the first in the industry of sheet metal processing machinery in the world.

The 21st century intelligent automatic sheet metal processing center developed and manufactured by the company in the 1990s has set a precedent for intelligent processing in the world sheet metal industry.

The reason why AMADA’s products are welcomed by users all over the world is that they have a reasonable mechanical structure, can provide users with high quality assurance, have effective pollution-free operation characteristics, can create benefits for users, and can provide users with assurance of use.

The products have the advanced technology of imitative town automation, which can provide users with simplified processing guarantee, so that AMADA’s products can spread all over the world, and the company’s annual sales reach 200 billion yen.

Since the founding of the People’s Republic of China in 1949, AMADA opened its office in Beijing in 1983, and established three local legal persons engaged in sales and services, Beijing Tiantian Machine Tool Mold Co., Ltd., Tiantian International Industry and Trade (Shanghai) Co., Ltd. and AMADA International Trade (Shenzhen) Co., Ltd. respectively in 1993, 1996 and 2001.

In addition, in 1996, AMADA (Shanghai) Machine Tool Co., Ltd. was established in Shanghai to produce punch, bending machine and other products.

At present, a manufacturing plant including a technical center is being built in Qingpu District, Shanghai.

In 2003, AMADA (Lianyungang) Machine Tool Co., Ltd., a company engaged in the production, sales and service of band saws and saw blades, was established.

AMADA will set up a regional company in Shanghai with a registered capital of 2.5 billion yen, which will govern the business in China.

In the future, AMADA will develop and manufacture products that can meet the needs of Chinese customers, give full play to the financial strength of AMADA Group, carry out manufacturer financing, lease sales and other businesses, and study and implement the sales strategy that will make it easier for customers to purchase AMADA equipment.

7. Penta laser

Country: China

Founded: 2007

About the company:

Founded in 2007, Penta Laser is a group company specializing in the R&D, manufacturing and sales of laser cutting and welding equipment.

The company is headquartered in Wenzhou Economic and Technological Development Zone, Zhejiang Province.

It has four manufacturing bases in Wuhan, Wenzhou, Linyi and Florence, Italy.

In 2021, the sales contract amount of the group will exceed 2.5 billion yuan.

It is an advanced enterprise of high-power laser cutting and welding equipment in China.

Penta Laser is a national green factory, a deputy director unit of Laser Processing Special Committee of China Optical Society, a member unit of China Optical Radiation Safety and Laser Equipment Standardization Branch Committee, a director unit of Laser Processing Special Committee of Zhejiang Machinery Industry Federation, and a chairman unit of Wenzhou Laser Industry Association.

At present, Penta Laser has 960 employees (including about 100 Italian employees), and the plant area exceeds 100000 square meters.

Penta Group has more than 5000 customers in China. CRRC Group, CIMC Group, Sany Heavy Industry, Zoomlion Heavy Industry, XCMG Group, Shanzhong Group and other large enterprise groups use Pentium laser products in large quantities.

Penta laser cutting and welding equipment is exported to the United States, Britain, Germany, France, Australia, Japan, South Korea and other developed countries and regions.

It is an excellent enterprise for the export of high-power laser cutting equipment.

Cutlite, a wholly-owned subsidiary of the Group, is an advanced laser cutting machine company in Europe.

Penta Laser is an innovation driven enterprise.

The company has a research and development team of more than 200 people, including more than 20 foreign research and development personnel, and more than 30 master’s and doctoral research and development personnel.

5% of the annual sales amount is invested in new product development.

It has more than 100 laser technology patents, and is specialized in developing high-end high-power laser cutting equipment and processes, large, medium and small laser pipe cutting equipment, large gantry 3D laser cutting and welding equipment, laser blanking automation production line and other products, as well as control systems, laser cutting and welding heads and other core components.

It has R&D platforms such as Zhejiang Enterprise Research Institute, Provincial Enterprise Technology Center, and Provincial Engineering Research Center.

The 8000W laser cutting machine won the second prize of Zhejiang Science and Technology Progress Award, the groove laser cutting equipment won the gold medal of China Laser Golden Yao Award, the 20KW laser cutting equipment won the first set of national major technical equipment products, and the 30KW laser cutting equipment won the first set of international major equipment products.

At the end of 2021, the 40KW laser cutting equipment independently developed by Penta has been successfully developed and put into use.

Penta Laser is a digital factory.

The company has comprehensive software management platforms such as ERP cloud operation system, MES intelligent manufacturing system, PLM R&D system, and remote operation and maintenance CRM service system.

It realizes data sharing with suppliers and customers, whole process monitoring of quality and progress during product manufacturing, and real-time monitoring of equipment running at customers.

It took the lead in entering a new stage of intelligent manufacturing of laser equipment.

8. PrimaPower

Country: Italy

Founded: 1977

About the company:

As a leader in sheet metal processing machinery and systems, PrimaPower’s products cover all applications such as laser processing, stamping, shearing, bending and automation, and is one of the manufacturers with a wide range of products in this field.

The company’s manufacturing plants are located in Italy, Finland, the United States and China, and the equipment and systems are sent to all parts of the world from these countries.

The sales and service network directly led by our company or composed of professional dealers covers more than 80 countries around the world.

The company’s product lines include The PUNCH, The LASER, The COMBI, The BEND, The SYSTEM and The SOFTWARE, covering all stages of sheet metal processing.

The company has a wide range of highly sophisticated servo electric solutions for stamping, bending and integrated processing in the world. Its marketing slogan is “effective use of energy”.

As an unquestionable leader in the field of 3D laser equipment, the company is also one of the world’s major players in the field of 2D laser;

Its two-dimensional laser equipment has outstanding performance and ultra-high efficiency, and is widely used in many fields around the world.

Service is a very important part of PrimaPower’s activities.

PrimaPower is dedicated to providing professional, dedicated and effective support to every customer in the world.

The development of all products of the company always adheres to the concept of green and environmental protection, and fully considers the coordinated development of sustainability and productivity.

9. Messer

Country: Germany

Founded: 1898

About the company:

Messer is a global solution provider for the metalworking industry.

The company is engaged in the design of oxygen and gas, plasma and laser cutting systems, which can help users better achieve the goal of producing high productivity, flexibility and high-quality products.

The research and development of Messer cutting system has always been based on the needs of customers and customers, hoping that customers can experience the quality, accuracy, durability, reliability and innovation strength of Messer cutting system from contact with our sales team and machines to after-sales service.

The company hopes that customers can feel the experience of Messer.

Therefore, the company is cooperating with customers and partners to develop and test cutting-edge and high-quality technologies under realistic conditions.

In this way, when the company’s machines, software and services are involved, customers around the world can benefit from excellent solutions.

10. HGTECH

Country: China

Founded: 1999

About the company:

As a high-tech enterprise, Huagong Science and Technology Industry Co., Ltd. was founded in 1999 and listed on Shenzhen Stock Exchange in 2000.

It is a listed enterprise with a university background in central China and a high-tech enterprise with laser as its main business in China’s capital market.

Taking “laser technology and its application” as the main business, Huagong Technology, based on the formed industrial pattern of laser equipment manufacturing, optical communication devices, laser holographic counterfeiting, sensors and information tracing, focuses on superior resources to develop key products and solutions for intelligent manufacturing in accordance with the global “re industrialization” development trend and its own characteristics.

Adhering to the enterprise mission of “higher honor for manufacturing”, the products of the company’s enterprises, including Huagong Laser, Huagong Zhengyuan, Huagong Gaoli, Huagong Image and Huagong Saibai, are widely used in important fields such as machinery manufacturing, aerospace, automobile industry, iron and steel metallurgy, shipbuilding industry and communication network.

Huagong Science and Technology is committed to providing cost-effective products and services to global users, and has established partnerships with many global top 500 enterprises.

The company strives to create an innovative environment that is pioneering and tolerant of failure.

It has introduced and trained more than 1000 excellent domestic technicians, accounting for about 18% of the total number of the company.

Relying on the Enterprise Technology Center, the National Key Laboratory of Laser Technology of the National Laser Engineering, the National Engineering Center of Laser Processing, and the Sensitive Ceramics Engineering Research Center of the Ministry of Education, Huagong Science and Technology has carried out multi-level technical exchanges and cooperation with domestic and foreign scientific research institutes and research institutions, zero distance docking with advanced technologies, and has successively undertaken more than 50 major projects.

The company invests 6% – 10% of its sales revenue in R&D every year.

Since its establishment, it has developed more than 263 new products and technologies, with an average annual contribution rate of 35.2%, applied for 168 patents, and participated in drafting and presiding over the formulation of 7 national standards.

In 2000, Huagong Technology acquired Farley Laserlab, a famous global cutting system company, to start the international journey.

Relying on the three-level model of “branch+office+agent”, Huagong Technology competes with international outstanding enterprises in high-end mainstream markets and sells its products to more than 50 countries and regions around the world, changing the landscape of the world’s laser industry.

Factors to Consider When Choosing a Manufacturer

Cutting Quality and Precision

When choosing a laser cutting machine manufacturer, I consider the cutting quality and precision of their machines. I look for manufacturers that consistently deliver clean and precise cuts, ensuring a high standard of quality in my finished products. Additionally, I take into account the technology and materials used in the machines, as these can affect the cutting performance.

Pricing

As pricing can significantly impact my budget, I research various laser cutting machine manufacturers to compare their prices. I weigh this against the features and benefits offered by each manufacturer to ensure I’m getting the best value for my money. Transparency in pricing is also essential, as hidden costs can quickly add up and affect my bottom line.

Service and Support

When selecting a manufacturer, I prioritize those that offer exceptional service and support. This includes proper communication, reliable customer service, and timely assistance in addressing concerns or solving issues. It’s crucial for me to partner with a responsive manufacturer that values my time and helps me keep my operations running smoothly.

Machine Compatibility

Finally, I assess each manufacturer’s machine compatibility with my production needs and processes. This involves considering factors such as the machine’s size, power, and operational capabilities. Additionally, I check for compatibility with the materials I work with and any software requirements that may be necessary for efficient production.

By factoring in cutting quality and precision, pricing, service and support, and machine compatibility, I can make an informed decision when choosing a laser cutting machine manufacturer to partner with in my business.

Emerging Trends in Laser Cutting Machine Manufacturing

Fiber Lasers

In recent years, I have observed a significant shift towards fiber lasers in laser cutting machine manufacturing. These lasers have proven to be more efficient and reliable than their traditional CO2 counterparts. They offer a faster cutting speed and lower operating costs, which has made them increasingly attractive to manufacturers and buyers alike. Their compact size and lower maintenance requirements have further boosted their popularity.

Automation

I have also seen that automation is playing a more prominent role in laser cutting machine manufacturing. This development is driven by the need for higher output rates and better process control. Automated loading and unloading systems, for instance, are becoming more common, streamlining the production process and reducing labor costs. Additionally, advanced software solutions are enabling more precise control of cutting parameters and better monitoring of machine performance.

Environment-Friendly Solutions

Lastly, it’s essential to recognize the emerging trend towards environmentally friendly solutions in laser cutting machine manufacturing. Manufacturers are increasingly designing machines to reduce their overall energy consumption and use more eco-friendly cooling systems. Some companies are also looking into alternative energy sources, such as solar power, to further minimize their environmental impact.

Conclusion

In my research on top laser cutting machine manufacturers, I have found that several companies stand out among the rest. These manufacturers produce high-quality, reliable machines that are popular among professionals and hobbyists alike.

Some of the key companies include:

- Trumpf: A German company known for their advanced technology and precision laser cutting machines, offering a wide range of models for various industries.

- Bystronic: A Swiss manufacturer that focuses on producing high-performance machines for sheet metal processing with a focus on automation and efficiency.

- Amada: A Japanese company with a long history of providing reliable and versatile machines, suitable for various industries and applications.

These manufacturers excel in creating machines that cater to various needs, while continuously working to improve their technologies and customer satisfaction. Choosing the right laser cutting machine requires careful consideration of factors like budget, materials, and intended applications. For those who prioritize reliable, high-quality machines, companies like Trumpf, Bystronic, and Amada are top contenders in the market.

If you want to buy fiber laser cutting machine with good quality as well as affordable price, please contact us right now to get FREE quote.