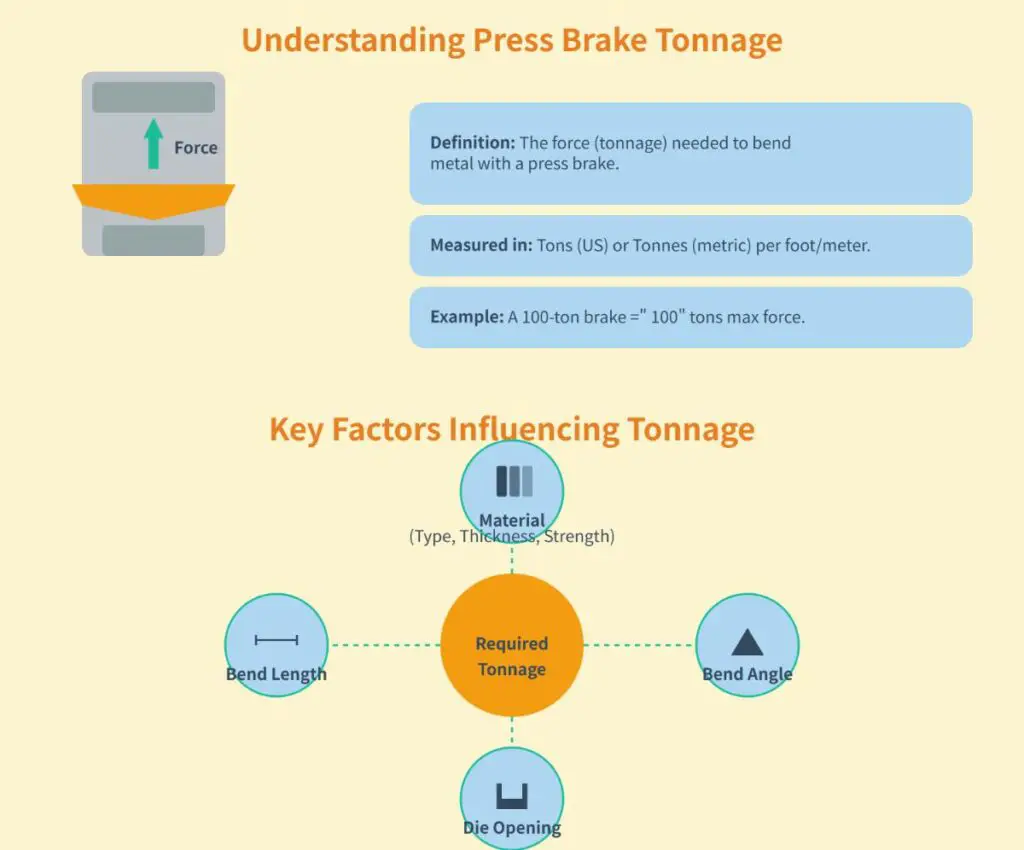

What Is Press Brake Tonnage?

Press brake tonnage refers to the force required to bend metal using a press brake machine. It is typically measured in tons (short tons in the US) or metric tons (tonnes) per foot or meter of bend length. For instance, a 100-ton press brake can exert up to 100 tons of force along its entire bed length.

The tonnage required depends on several factors:

- Material properties (type, thickness, tensile strength)

- Bend angle

- Die opening width

- Length of the bend

Press Brake Tonnage Calculator

As you know, different countries use different units, some countries use metric units and others use British units. For your convenience, the tonnage calculator of the press brake machine we made can meet the above two different needs at the same time.

If you want to know more about the calculation formula of press brake tonnage, you can refer to this article. Enjoy it.

Recommended V opening of the bottom die

| Material thickness S | 0.5-2.5mm | 3-8mm | 9-10mm | >12mm |

| Bottom die V opening | 6×S | 8×S | 10×S | 12×S |

Bending inner radius from V-die opening

| Material | V |

| Mild steel | 1/6 × V |

| Stainless | 1/5 × V |

| Aluminium | 1/8 × V |

Required tonnage for other metals

| Soft brass | Tonnage × 0.5 |

| Soft aluminium | Tonnage × 0.5 |

| Stainless steel | Tonnage × 1.5 |

| High strength steel | Tonnage ×2.75 |

Hemming tonnage mild steel

| t,mm | Tear,t/m | Full hem |

| 0.6 | 9 | 23 |

| 1 | 15 | 40 |

| 1.5 | 22 | 63 |

| 2 | 30 | 80 |

| 2.5 | 55 | 90 |

| 3 | 77 | 100 |

Related calculator: Bending Load Calculator (V, U, Wipe Bending)

The Formula for Press Brake Tonnage Calculation

Calculating the tonnage requirements for a press brake operation is essential to ensure accurate bending without damaging the equipment or the workpiece. The standard formula used for tonnage calculation is as follows:

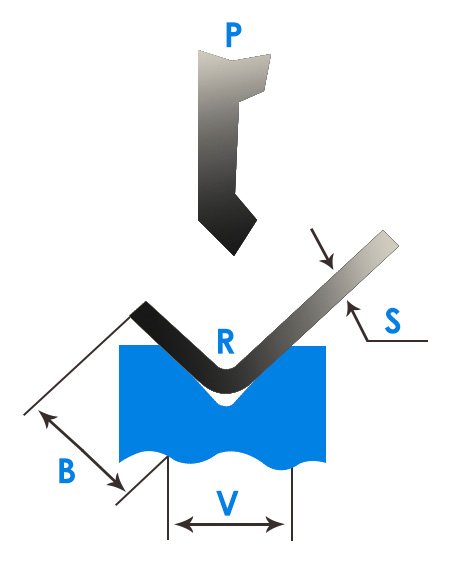

(when σb = 450N/mm²)

Here, P represents the tonnage required, S is material thickness (in mm), L is the bend length (in mm), and V is the die opening (in mm). In this formula, σb is the material’s tensile strength (in N/mm²).

Another variation of the formula for estimating the tonnage requirement is:

Both these formulas offer a reliable means to calculate the tonnage required for an air bend operation.

Calculation example:

- Material: mild steel

- Thickness: 4mm

- Bending length: 3000mm

- Die opening: 8×4=32

If we calculate by the first formula, we get:

P=650×4²×3/32=975KN

975KN=99.49Ton

If we calculate by the second formula, we get:

P=1.42×450×4²×3/32=958.5KN

958.5KN=97.8Ton

Using two different calculation methods, we obtained a bending pressure close to 100 tons. Considering the safety factor, we recommend selecting a bending machine with a bending pressure of at least 120 tons.

Key Variables in Tonnage Calculation

Accurate tonnage calculation relies on a thorough understanding of several critical variables. This section examines these variables in detail, exploring how they interact and influence the force required for precise metal bending.

A. Material properties

- Material type and tensile strength

Different materials require varying amounts of force to bend due to their unique molecular structures and mechanical properties. The key property affecting tonnage requirements is tensile strength.

- Mild steel (ASTM A36): With a tensile strength of approximately 58,000 psi, this is often used as a baseline for tonnage calculations.

- Stainless steel (304): Has a tensile strength of about 85,000 psi, requiring roughly 1.5 times the tonnage of mild steel.

- Aluminum (6061-T6): Despite its lower tensile strength of 45,000 psi, its unique properties often necessitate tonnage similar to mild steel.

A study published in the Journal of Materials Processing Technology (2021) found that high-strength steels with tensile strengths exceeding 100,000 psi can require up to 2.5 times the tonnage of mild steel for equivalent bending operations.

- Thickness

Material thickness has an exponential effect on required tonnage. The relationship is typically expressed as:

Tonnage ∝ (Thickness)²

For example, doubling the material thickness quadruples the required tonnage. This relationship was confirmed in a comprehensive analysis by the Precision Metalforming Association, which examined over 10,000 bending operations across various industries.

B. Bending parameters

- Bend length

Tonnage requirements increase linearly with bend length. A simple formula often used is:

Total Tonnage = Tonnage per foot × Bend length (in feet)

For instance, if a particular bend requires 20 tons per foot, a 5-foot bend would need 100 tons of force.

- V-die opening

The width of the V-die opening significantly affects tonnage requirements. A wider opening reduces the required force but may impact bend accuracy. The optimal V-die width is typically 8 times the material thickness for air bending.

A study in the International Journal of Machine Tools and Manufacture (2023) found that increasing the V-die width from 6 to 8 times the material thickness can reduce tonnage requirements by up to 25% while maintaining bend accuracy within ±0.5 degrees.

- Bend angle

Sharper bend angles require more force. While 90-degree bends are most common, angles can vary widely depending on the application.

- 30-degree bend: Typically requires about 60% of the tonnage needed for a 90-degree bend.

- 120-degree bend: May require up to 130% of the tonnage for a 90-degree bend.

These relationships were established through extensive testing by the Fabricators & Manufacturers Association and are widely used in industry-standard tonnage calculators.

C. Tooling factors

- Standard tooling

Standard V-dies and punches are the baseline for most tonnage calculations. However, even within standard tooling, variations can affect tonnage requirements:

- Punch radius: A smaller radius typically requires more tonnage but produces a sharper bend.

- Die shoulder radius: A larger radius can reduce tonnage requirements but may affect bend accuracy.

- Special tooling (e.g., hemming, offset tools)

Specialized tooling often requires adjustment factors to standard tonnage calculations:

- Hemming tools: Can require up to 4 times the tonnage of standard V-dies for the same material.

- Offset tools: May need 1.5 to 2 times the standard tonnage due to the complex stress distribution during bending.

A 2022 survey of metal fabrication shops by the Precision Metalforming Association revealed that shops using specialized tooling without proper tonnage adjustments experienced a 35% higher rate of tool failure and part rejection.

Optimizing Press Brake Operations

A. Selecting the right machine capacity

Choosing a press brake with appropriate tonnage capacity is crucial for efficient and safe operations:

- Matching capacity to requirements:

Ideally, a press brake should operate at 80-90% of its rated capacity for optimal performance. A study by the Precision Metalforming Association (2023) found that machines consistently operating below 60% or above 95% of their rated capacity experienced 25% higher maintenance costs over a five-year period. - Considering future needs:

When selecting a machine, factor in potential future requirements. A common rule of thumb is to choose a press brake with 20-30% more capacity than current maximum needs to accommodate future growth or unexpected job requirements. - Distributed load considerations:

For long parts, consider machines with crowning systems to ensure even force distribution.

B. Choosing appropriate tooling

Proper tooling selection can significantly impact required tonnage and bend quality:

- Die selection:

Wider die openings generally require less tonnage but may affect bend accuracy. A 2022 study in the Journal of Manufacturing Processes found that increasing the die width from 6 to 8 times material thickness reduced required tonnage by up to 18% while maintaining bend angle accuracy within ±0.5 degrees. - Punch radius:

Smaller punch radii create sharper bends but require more tonnage. For example, reducing the punch radius from 1/32″ to 1/64″ for a 90-degree bend in 16-gauge mild steel can increase required tonnage by approximately 15%. - Specialized tooling:

Consider specialized tools for complex parts. Rotational bending tools, for instance, can reduce tonnage requirements for certain geometries by up to 40% compared to traditional V-die bending.

C. Fine-tuning bending parameters

Optimizing bending parameters can lead to significant improvements in efficiency and part quality:

- Bend sequence optimization:

Proper sequencing of bends can reduce overall tonnage requirements and improve accuracy. The Amada VPSS 3i software, for example, includes an automatic bend sequence optimizer that can reduce total tonnage requirements by up to 25% for complex parts with multiple bends. - Speed and dwell time adjustments:

Adjusting ram speed and dwell time at the bottom of the stroke can affect springback and required tonnage. A study in the International Journal of Machine Tools and Manufacture (2023) demonstrated that optimizing these parameters could reduce springback by up to 30% in high-strength steels. - Back gauge positioning:

Precise back gauge positioning ensures consistent bend location and can reduce required tonnage by preventing overbending. Modern systems like the Trumpf ACB (Automatically Controlled Bending) can adjust back gauge position in real-time based on measured springback, improving accuracy and reducing tonnage requirements.

D. Springback compensation techniques

Managing springback is crucial for achieving accurate bends while minimizing required tonnage:

- Overbending:

Traditional overbending requires higher tonnage but can be optimized. - Active angle measuring systems:

Systems measure bend angles in real-time during the bending process, allowing for immediate adjustments and reducing the need for overbending. - Material-specific strategies:

Different materials require different springback compensation approaches. For instance, aluminum typically requires 2-3 times more springback compensation than mild steel for equivalent thicknesses.

Implementing these optimization strategies can lead to significant improvements in press brake operations. A case study published in the Journal of Cleaner Production (2024) reported that a medium-sized fabrication shop achieved a 22% increase in productivity, 15% reduction in material waste, and 18% decrease in energy consumption after implementing a comprehensive press brake optimization program based on accurate tonnage calculations and parameter fine-tuning.

By carefully selecting machines and tooling, fine-tuning bending parameters, and employing advanced springback compensation techniques, manufacturers can maximize the benefits of accurate tonnage calculations, leading to improved part quality, reduced waste, and increased overall efficiency.

Glossary of Tonnage Calculation Terms

To ensure a comprehensive understanding of press brake tonnage calculation, it’s essential to have a clear grasp of the terminology used in the field. This glossary provides definitions for key terms, abbreviations, and symbols commonly encountered in tonnage calculation and press brake operations.

A. Basic Terms

- Tonnage:

The force required to bend metal, typically measured in tons or metric tonnes. - Press Brake:

A machine tool used to bend sheet metal by clamping it between a punch and die. - Air Bending:

A bending method where the punch does not bottom out in the die, typically requiring the least tonnage. - Bottom Bending:

A bending method where the punch contacts the bottom of the die, requiring more tonnage than air bending. - Coining:

A bending method that uses extreme force to stamp the metal between the punch and die, requiring the most tonnage.

B. Material-Related Terms

- Tensile Strength:

The maximum stress that a material can withstand while being stretched before breaking. - Yield Strength:

The stress at which a material begins to deform plastically. - K-Factor:

A value used to calculate the neutral axis in a bend, affecting tonnage calculations. - Springback:

The tendency of metal to partially return to its original shape after bending.

C. Tooling Terms

- V-Die:

The lower part of the bending tool with a V-shaped opening. - Punch:

The upper part of the bending tool that presses the material into the die. - Die Opening:

The width of the V-die, a critical factor in tonnage calculations. - Punch Radius:

The radius of the punch tip, affecting the inside radius of the bend.

D. Calculation-Related Terms

- Bend Allowance:

The length of the arc through the bend at the material’s neutral axis. - Bend Deduction:

The difference between the sum of the flange lengths and the overall length of the flat pattern. - Bend Angle:

The angle through which the material is bent, typically measured from the inside of the bend. - Bend Length:

The length of the bend along the axis of the bend.

E. Advanced Terms

- Crowning:

The slight convex curve applied to the bed or ram of a press brake to compensate for deflection under load. - Adaptive Bending:

A process where the press brake automatically adjusts parameters based on real-time feedback. - Tonnage Envelope:

The range of tonnage a press brake can safely apply across its bed length.

F. Abbreviations and Symbols

- CNC: Computer Numerical Control

- FEA: Finite Element Analysis

- OEE: Overall Equipment Effectiveness

- HSS: High-Strength Steel

- UHSS: Ultra-High-Strength Steel

- IoT: Internet of Things

- AI: Artificial Intelligence

- ML: Machine Learning

- σ (sigma): Used to represent stress in calculations

- ε (epsilon): Used to represent strain in calculations

- E: Young’s Modulus, a measure of a material’s stiffness

G. Industry-Specific Terms

- Forming Limit Diagram (FLD):

A graphical representation of a material’s formability limits. - Minimum Bend Radius:

The smallest radius that can be bent without damaging the material. - Bend Allowance Factor (BAF):

A coefficient used in bend allowance calculations, varying by material and bend angle. - Tonnage Per Meter (TPM):

A measure of required bending force per unit length, commonly used in metric systems.

H. Emerging Technology Terms

- Digital Twin:

A virtual representation of a physical press brake used for simulation and optimization. - Predictive Tonnage Modeling:

Using AI and historical data to predict required tonnage for new parts or materials. - Force Distribution Analysis (FDA):

Advanced calculation of how bending forces are distributed along the length of a bend. - Real-Time Material Property Sensing (RTMPS):

Emerging technology to measure material properties during the bending process. - Blockchain Tonnage Verification (BTV):

Using blockchain technology to ensure the integrity and traceability of tonnage calculations.

Understanding these terms is crucial for anyone involved in press brake operations, from operators and programmers to engineers and managers. As the field continues to evolve, new terms will likely emerge, reflecting advancements in technology and methodology.

This glossary serves as a foundation for clear communication and understanding in the complex world of press brake tonnage calculation. It’s important to note that while these definitions are generally accepted, slight variations may exist across different manufacturers or regions. Always refer to specific equipment manuals or industry standards for the most precise definitions in your particular context.