Understanding Sheet Metal Gauges

Sheet metal gauge charts are indispensable tools in metal fabrication, providing a standardized numerical representation of metal thickness. These charts simplify material selection and ensure consistency across manufacturing processes by offering a unified reference system for sheet metal dimensions.

Gauge and Thickness Relationship

The sheet metal gauge system follows a counterintuitive inverse relationship where a higher gauge number indicates a thinner piece of metal. For example, a 30-gauge sheet is significantly thinner than a 20-gauge sheet. This inverse correlation is crucial for fabricators to understand when specifying materials for various applications, from lightweight consumer electronics to robust industrial equipment.

Standard Gauge Systems

Gauge sizes are not universally standardized across all materials or regions. The United States predominantly uses the Manufacturers’ Standard Gauge for sheet steel, which differs from other country-specific systems like the Imperial Standard Wire Gauge (SWG) used in the UK. To facilitate global manufacturing and trade, standard gauge charts commonly display measurements in both imperial (inches) and metric (millimeters) units, allowing for easy conversion and international compatibility.

Gauge Variation in Different Materials

Different materials adhere to distinct gauge charts due to variations in density, malleability, and typical applications. For instance:

- Stainless steel utilizes its own gauge chart, reflecting its unique properties and common uses in corrosion-resistant applications.

- Aluminum thickness is measured using an aluminum-specific gauge chart, accounting for its lighter weight and different strength-to-thickness ratio compared to steel.

- Copper and brass often follow the Brown & Sharpe (B&S) gauge system, which is tailored to non-ferrous metals.

This distinction is crucial for precision in material selection, ensuring that the chosen gauge meets the specific strength, weight, and performance requirements of a given project. Engineers and fabricators must be vigilant in referencing the correct gauge chart for each material to avoid costly errors in design and production.

Understanding these nuances in sheet metal gauges is essential for effective communication between designers, manufacturers, and suppliers in the metal fabrication industry. It enables accurate material specification, optimizes production processes, and ensures the final product meets the intended structural and functional requirements.

Commonly Used Sheet Metal Gauges

The gauge system is a standardized method for specifying sheet metal thickness, widely adopted by industry professionals for efficient material referencing. It’s crucial to note that for most metals, there’s an inverse relationship between gauge number and material thickness: as the gauge number increases, the thickness decreases.

Steel Gauge Chart

The sheet metal gauge is a standardized system used to indicate the thickness of metal sheets. Counterintuitively, as the gauge number increases, the thickness of the metal sheet decreases. It’s crucial to note that gauge numbers correspond to different thicknesses for various metal types, making it essential to specify the material when referencing gauge measurements.

For steel, the most commonly used gauge numbers range from 3 to 30. The standard gauges for steel are historically based on the weight of a standard-sized sheet rather than a direct thickness measurement. This weight-based system has been standardized over time to correspond to specific thicknesses. Below is a comprehensive chart detailing common steel gauges with their corresponding thicknesses in both inches and millimeters:

| Gauge | US Standard Gauge | Sheet Steel | Galvanized Steel | Stainless Steel | Aluminum | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | |

| 7/00 | 0.5 | 12.7 | ||||||||

| 6/00 | 0.469 | 11.908 | 0.469 | 11.905 | 0.58 | 14.732 | ||||

| 5/00 | 0.438 | 11.113 | 0.438 | 11.113 | 0.517 | 13.119 | ||||

| 4/00 | 0.406 | 10.32 | 0.406 | 10.317 | 0.46 | 11.684 | ||||

| 3/00 | 0.375 | 9.525 | 0.375 | 9.525 | 0.41 | 10.404 | ||||

| 2/00 | 0.344 | 8.733 | 0.344 | 8.73 | 0.365 | 9.266 | ||||

| 1/00 | 0.313 | 7.938 | 0.313 | 7.938 | 0.325 | 8.252 | ||||

| 1 | 0.281 | 7.145 | 0.281 | 7.142 | 0.289 | 7.348 | ||||

| 2 | 0.266 | 6.746 | 0.266 | 6.746 | 0.258 | 6.543 | ||||

| 3 | 0.25 | 6.35 | 0.239 | 6.073 | 0.25 | 6.35 | 0.229 | 5.827 | ||

| 4 | 0.234 | 5.954 | 0.224 | 5.695 | 0.234 | 5.954 | 0.204 | 5.189 | ||

| 5 | 0.219 | 5.558 | 0.209 | 5.314 | 0.219 | 5.555 | 0.182 | 4.62 | ||

| 6 | 0.203 | 5.159 | 0.194 | 4.935 | 0.203 | 5.159 | 0.162 | 4.115 | ||

| 7 | 0.188 | 4.763 | 0.179 | 4.554 | 0.188 | 4.763 | 0.144 | 3.665 | ||

| 8 | 0.172 | 4.366 | 0.164 | 4.176 | 0.168 | 4.267 | 0.172 | 4.366 | 0.129 | 3.264 |

| 9 | 0.156 | 3.97 | 0.15 | 3.797 | 0.153 | 3.886 | 0.156 | 3.967 | 0.114 | 2.906 |

| 10 | 0.141 | 3.571 | 0.135 | 3.416 | 0.138 | 3.505 | 0.141 | 3.571 | 0.102 | 2.588 |

| 11 | 0.125 | 3.175 | 0.12 | 3.038 | 0.123 | 3.124 | 0.125 | 3.175 | 0.091 | 2.304 |

| 12 | 0.109 | 2.779 | 0.105 | 2.657 | 0.108 | 2.743 | 0.109 | 2.779 | 0.081 | 2.052 |

| 13 | 0.094 | 2.383 | 0.09 | 2.278 | 0.093 | 2.362 | 0.094 | 2.38 | 0.072 | 1.829 |

| 14 | 0.078 | 1.984 | 0.075 | 1.897 | 0.079 | 2.007 | 0.078 | 1.984 | 0.064 | 1.628 |

| 15 | 0.07 | 1.786 | 0.067 | 1.709 | 0.071 | 1.803 | 0.07 | 1.786 | 0.057 | 1.45 |

| 16 | 0.063 | 1.588 | 0.06 | 1.519 | 0.064 | 1.626 | 0.063 | 1.588 | 0.051 | 1.29 |

| 17 | 0.056 | 1.43 | 0.054 | 1.367 | 0.058 | 1.473 | 0.056 | 1.427 | 0.045 | 1.151 |

| 18 | 0.05 | 1.27 | 0.048 | 1.214 | 0.052 | 1.321 | 0.05 | 1.27 | 0.04 | 1.024 |

| 19 | 0.044 | 1.113 | 0.042 | 1.062 | 0.046 | 1.168 | 0.044 | 1.11 | 0.036 | 0.912 |

| 20 | 0.038 | 0.953 | 0.036 | 0.912 | 0.04 | 1.016 | 0.038 | 0.953 | 0.032 | 0.813 |

| 21 | 0.034 | 0.874 | 0.033 | 0.836 | 0.037 | 0.94 | 0.034 | 0.874 | 0.029 | 0.724 |

| 22 | 0.031 | 0.795 | 0.03 | 0.759 | 0.034 | 0.864 | 0.031 | 0.792 | 0.025 | 0.643 |

| 23 | 0.028 | 0.714 | 0.027 | 0.683 | 0.031 | 0.787 | 0.028 | 0.714 | 0.023 | 0.574 |

| 24 | 0.025 | 0.635 | 0.024 | 0.607 | 0.028 | 0.711 | 0.025 | 0.635 | 0.02 | 0.511 |

| 25 | 0.022 | 0.556 | 0.021 | 0.531 | 0.025 | 0.635 | 0.022 | 0.556 | 0.018 | 0.455 |

| 26 | 0.019 | 0.478 | 0.018 | 0.455 | 0.022 | 0.559 | 0.019 | 0.475 | 0.016 | 0.404 |

| 27 | 0.017 | 0.437 | 0.016 | 0.417 | 0.02 | 0.508 | 0.017 | 0.437 | 0.014 | 0.361 |

| 28 | 0.016 | 0.396 | 0.015 | 0.378 | 0.019 | 0.483 | 0.016 | 0.396 | 0.013 | 0.32 |

| 29 | 0.014 | 0.358 | 0.014 | 0.343 | 0.017 | 0.432 | 0.014 | 0.358 | 0.011 | 0.287 |

| 30 | 0.013 | 0.318 | 0.012 | 0.305 | 0.016 | 0.406 | 0.013 | 0.318 | 0.01 | 0.254 |

| 31 | 0.011 | 0.277 | 0.011 | 0.267 | 0.011 | 0.277 | 0.009 | 0.226 | ||

| 32 | 0.01 | 0.259 | 0.01 | 0.246 | 0.01 | 0.259 | 0.008 | 0.203 | ||

| 33 | 0.009 | 0.239 | 0.009 | 0.229 | 0.009 | 0.239 | 0.007 | 0.18 | ||

| 34 | 0.009 | 0.218 | 0.008 | 0.208 | 0.009 | 0.218 | 0.006 | 0.16 | ||

| 35 | 0.008 | 0.198 | 0.008 | 0.191 | 0.008 | 0.198 | 0.006 | 0.142 | ||

| 36 | 0.007 | 0.178 | 0.007 | 0.17 | 0.007 | 0.178 | 0.005 | 0.127 | ||

| 37 | 0.007 | 0.168 | 0.006 | 0.163 | 0.007 | 0.168 | 0.005 | 0.114 | ||

| 38 | 0.006 | 0.16 | 0.006 | 0.152 | 0.006 | 0.157 | 0.004 | 0.102 | ||

| 39 | 0.006 | 0.15 | ||||||||

| 40 | 0.006 | 0.14 | ||||||||

| 41 | 0.005 | 0.135 | ||||||||

| 42 | 0.005 | 0.13 | ||||||||

| 43 | 0.005 | 0.124 | ||||||||

| 44 | 0.005 | 0.119 | ||||||||

Industrial Applications of Sheet Metal Gauges

Sheet metal gauge charts are indispensable in various industrial applications, providing a standardized reference for material thickness. They guide fabrication processes by specifying the appropriate thickness for different applications, ensuring structural integrity, functionality, material efficiency, and cost-effectiveness.

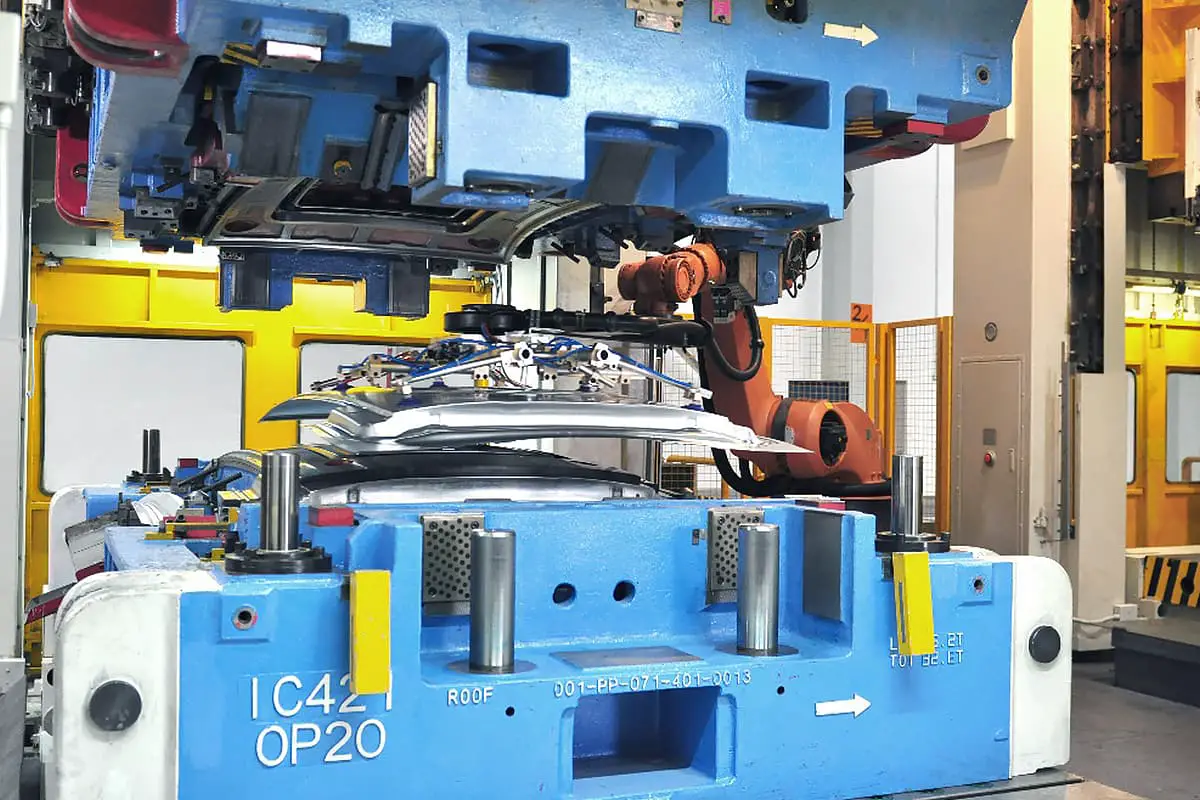

Automotive Industry Applications

In the automotive sector, sheet metal gauges are critical for precise manufacturing of vehicle components. The selection of appropriate gauges balances structural strength, weight management, and formability:

Body panels: Typically utilize 20-gauge (0.0359 inch / 0.912 mm) steel, offering a balance between strength and formability for complex shapes.

Car frames: Often constructed from 12- to 14-gauge steel (0.1046-0.0747 inch / 2.657-1.897 mm), depending on the required load-bearing capacity and crash resistance.

Underbody components: May use thicker 10-gauge (0.1345 inch / 3.416 mm) steel for enhanced durability against road debris and corrosion.

Aerospace Industry Applications

In aerospace, where weight reduction is paramount, sheet metal gauges help optimize the strength-to-weight ratio:

Fuselage: Usually constructed with aluminum alloy sheets between 18-gauge to 22-gauge (0.0478-0.0299 inch / 1.214-0.759 mm), with variations based on structural requirements and location on the aircraft.

Wings: Require a precise balance of lightness and strength, often utilizing 16-gauge to 20-gauge (0.0598-0.0359 inch / 1.519-0.912 mm) aluminum sheets, with thicker gauges used in high-stress areas.

Engine nacelles: May employ titanium sheets of 15-gauge to 18-gauge (0.0673-0.0478 inch / 1.709-1.214 mm) for heat resistance and strength.

Construction Industry Applications

In construction, sheet metal gauge charts guide material selection for durability, thermal efficiency, and cost-effectiveness:

Roofing: Typically ranges from 22-gauge to 29-gauge (0.0299-0.0141 inch / 0.759-0.358 mm), with thicker gauges for areas with heavy snowfall or high wind loads. Standing seam roofs often use 24-gauge (0.0239 inch / 0.607 mm) for optimal performance.

HVAC ducts: Commonly use 30-gauge to 24-gauge (0.0125-0.0239 inch / 0.318-0.607 mm) galvanized steel sheets. Thicker gauges contribute to better insulation, durability, and reduced noise transmission. Main supply trunks often use 24-gauge, while branch ducts may use 26-gauge (0.0179 inch / 0.455 mm).

Structural studs: Light gauge steel framing typically uses 25-gauge to 20-gauge (0.0209-0.0359 inch / 0.531-0.912 mm) for interior non-load bearing walls, and 18-gauge to 12-gauge (0.0478-0.1046 inch / 1.214-2.657 mm) for load-bearing applications.

Tools for Measuring Sheet Metal Gauges

Precision in measuring sheet metal thickness is crucial in manufacturing and engineering applications, ensuring adherence to project specifications and quality control standards. While traditional tools like calipers, micrometers, and gauge wheels remain widely used, advancements in technology have introduced more sophisticated measurement methods.

Calipers

Calipers, with their opposable arms, offer versatile measurement capabilities. Digital calipers have become industry standard due to their ease of use, rapid digital readout, and ability to switch between metric and imperial units. High-end models now incorporate Bluetooth connectivity for data logging and statistical process control (SPC) integration. For sheet metal applications, calipers with specially designed jaws for reaching into flanges or measuring rolled edges are particularly useful.

Micrometers

Micrometers provide highly precise measurements through their calibrated screw mechanism. Modern digital micrometers can achieve accuracies of up to ±0.001 mm (0.00004 inches), with some specialized models reaching ±0.1 μm (0.000004 inches). Advanced features include data output capabilities, temperature compensation, and programmable tolerance limits for go/no-go testing. For sheet metal, disc micrometers with large contact surfaces are preferred to minimize measurement errors on slightly uneven surfaces.

Gauge Wheels

Gauge wheels, or thickness gauges, offer rapid thickness assessment for sheet metal. Contemporary models integrate digital displays alongside the traditional rotating wheel, providing both visual reference and precise numerical readouts. Some advanced gauge wheels incorporate non-contact measurement technologies, such as ultrasonic or laser sensors, allowing for quick and accurate measurements without physical contact, which is particularly beneficial for delicate or coated sheet metals.

Emerging Technologies

Ultrasonic thickness gauges utilize sound waves to measure sheet metal thickness without contacting both sides of the material, making them ideal for installed or hard-to-reach components. Laser-based systems offer high-speed, non-contact measurements suitable for in-line quality control in sheet metal production. X-ray fluorescence (XRF) analyzers can simultaneously measure coating thickness and material composition, providing comprehensive material analysis in a single device.

Calibration and Maintenance

Regardless of the tool chosen, regular calibration and proper maintenance are essential for ensuring measurement accuracy. Many modern measurement devices feature built-in calibration routines and alerts, helping maintain measurement integrity in industrial environments.

By leveraging these advanced measurement tools and techniques, manufacturers can ensure precise thickness control in sheet metal fabrication, leading to improved product quality, reduced material waste, and enhanced process efficiency.

Standards and Specifications

In the sheet metal industry, precise standards established by organizations such as ASTM International and the International Organization for Standardization (ISO) guide manufacturers and consumers in determining the thickness, weight, and quality of metal sheets. These standards are crucial for ensuring consistency, reliability, and interoperability across global supply chains.

ASTM Standards

ASTM International has developed a comprehensive set of standards widely adopted in sheet metal manufacturing and related industries. These standards provide detailed specifications for various grades, materials, and processing methods, ensuring consistency across suppliers and applications. For example:

- ASTM A653/A653M: This standard specifies requirements for steel sheet, zinc-coated (galvanized) or zinc-iron alloy-coated (galvannealed) by the hot-dip process. It defines critical aspects such as coating weight, bend properties, and tensile strength for different grades. This standard is essential for applications ranging from automotive components to HVAC systems.

- ASTM B209/B209M: This specification covers aluminum and aluminum alloy sheet and plate for general-purpose applications. It meticulously defines chemical composition limits, mechanical property requirements, and permissible thickness variations. This standard is crucial for industries such as aerospace, where precise material properties are paramount.

- ASTM A240/A240M: Applicable to chromium and chromium-nickel stainless steel plate, sheet, and strip, this standard is vital for corrosion-resistant applications in chemical processing, food handling, and architectural metalwork.

ISO Standards

ISO standards provide an internationally recognized framework for metal gauge and sheet standards, facilitating global trade and ensuring consistent quality worldwide. Key ISO standards in sheet metal processing include:

- ISO 3575: This standard defines the specifications for continuously hot-dip zinc-coated carbon steel sheet of commercial and drawing qualities. It covers dimensions, tolerances, mechanical properties, and coating mass, ensuring uniformity in galvanized products across different manufacturers.

- ISO 9445-1 and ISO 9445-2: These standards specify dimensions and tolerances for cold-rolled stainless steel narrow strip and wide strip, respectively. They are crucial for maintaining precision in manufacturing processes that require tight dimensional control.

- ISO 6932: Applicable to hot-rolled steel plate, this standard outlines thickness tolerances and dimensional tolerances. It’s essential for heavy industrial applications, construction, and shipbuilding where material strength and dimensional accuracy are critical.

- ISO 16163: This standard specifies requirements for continuously hot-dip coated steel sheet products with improved formability for cold forming. It’s particularly relevant for automotive and appliance manufacturing where complex forming operations are common.

These standards not only ensure that materials meet consumers’ demands for reliability and quality across global markets but also facilitate innovation by providing a common language for material properties and performance. Adherence to these standards is often mandatory for compliance with building codes, safety regulations, and quality management systems like ISO 9001.

Manufacturers and engineers must stay abreast of updates to these standards, as they evolve to accommodate advancements in material science, processing technologies, and emerging industry needs. Understanding and implementing these standards is crucial for optimizing sheet metal fabrication processes, reducing waste, improving product quality, and ensuring regulatory compliance in diverse applications.

Safety Considerations in Handling Sheet Metal

When handling sheet metal, workers must prioritize safety due to the material’s sharp edges, potential for creating hazardous metal particles, and the risk of severe lacerations. Adherence to comprehensive safety protocols can significantly reduce the risk of accidents and injuries in metal fabrication environments.

Personal Protective Equipment (PPE): It is essential for individuals working with sheet metal to wear appropriate PPE, including:

- Cut-resistant gloves: Kevlar or high-performance polyethylene (HPPE) gloves to prevent lacerations and punctures

- Safety glasses with side shields: To protect eyes from metal shavings, debris, and potential chemical splashes

- Respiratory protection: NIOSH-approved respirators with appropriate filters for metal dust and fumes, especially during cutting or welding operations

- Steel-toed safety boots: To protect feet from falling metal sheets or tools

- Protective clothing: Long-sleeved shirts and pants made from durable, cut-resistant materials

Handling Procedures: Proper handling techniques are crucial to avoid physical harm:

- Utilize mechanical lifting devices (e.g., vacuum lifters, magnetic lifters) for large or heavy sheets to reduce manual handling risks

- Implement the “two-person lift” rule for sheets exceeding safe single-person lifting limits

- Use properly maintained and calibrated cutting and bending equipment to ensure precise control and reduce the risk of unexpected material behavior

- Employ deburring tools to remove sharp edges immediately after cutting operations

Workplace Engineering Controls:

- Install adequate local exhaust ventilation systems to capture metal dust and fumes at the source

- Use anti-fatigue mats in standing work areas to reduce musculoskeletal strain

- Implement noise control measures, such as sound-absorbing panels, to mitigate the risk of hearing damage from metal fabrication processes

Education and Training: Workers should receive comprehensive training, including:

- Proper lifting techniques and ergonomic practices to prevent musculoskeletal injuries

- Hazard recognition specific to sheet metal work, including identifying stressed or spring-loaded metal that may suddenly release

- Emergency response procedures, including first aid for common sheet metal injuries

- Proper use and maintenance of all PPE and fabrication equipment

Workplace Organization and Cleanliness:

- Implement a 5S (Sort, Set in Order, Shine, Standardize, Sustain) system to maintain an organized and safe work environment

- Regularly clean work areas to prevent accumulation of metal shavings and dust, reducing slip and respiratory hazards

- Properly dispose of metal scrap in designated containers to prevent injuries and contamination

By implementing these comprehensive safety measures, workers can significantly minimize the risks associated with handling sheet metal while maintaining productivity and efficiency in metal fabrication operations.